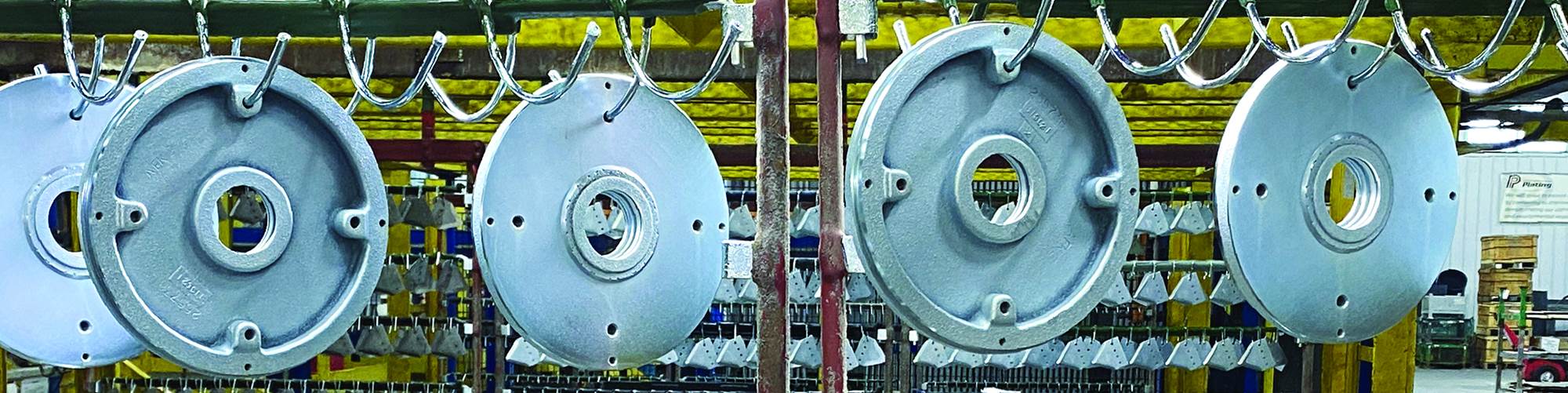

Professional Plating’s facility in Brillion, Wisconsin, comprises 200,000 square feet and multiple buildings with a variety of processes and systems. All photost: Professional Plating

Products Finishing recently embarked on a journey around the Midwest to visit a number of shops, which included a stop in Brillion, Wisconsin, to tour the facility of Professional Plating, a company that specializes in zinc plating, electrocoating and powder coating. The company, which serves a range of markets and industries, boasts its status as a one-stop-shop with solutions for most finishing needs. The expansive facility and its processes, as well as the teamwork-oriented dynamic on the shop floor, are two aspects that set Professional Plating apart and solidify its status as one of PF’s Top Shops.

Professional Plating’s operation, which started in 1979 with a zinc plating line and a barrel line, has drastically grown since it began. Over the years, the company has expanded its site into a 200,000-square-foot campus that now features a Cyclemaster rack line, an acrylic e-coating line, powder coating lines, wastewater treatment systems, a lab with precision testing equipment, storage and shipping areas and even a lounge and wellness center. Professional Plating’s General Manager, Larry Dietz, says, “We own everything from the storage buildings down to the woodlands.” And future additions are planned, with another barrel line being considered next. Dietz adds, “Right now, our barrel lines are probably our busiest capacity.”

The cleanliness and organization of Professional Plating’s facility enables its operations to run smoothly.

One aspect of Professional Plating’s facility that stood out most on the visit, aside from the impressive amount of processes and systems the company has packed onto its campus, is just how clean everything is. It would be impossible for a shop to run an operation of this scale without a keen sense of organization, and Professional Plating has it in spades. Walking into its facility is like stepping into an IKEA, where everything is neatly packed, racked or boxed up and ready to ship. Dietz says, “The system has to be strong, the processes have to be strong and the team has to believe in it.”

Cultivating a supportive shop culture

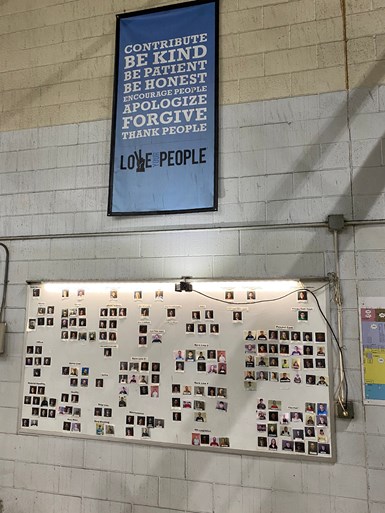

Facility aside, Professional Plating’s leadership sees its team as the company’s greatest asset, which is evidenced by the communal culture on the shop floor. As the company has grown and focused on continuous improvement, it has invested energy and resources not only in its finishing operations, but in the team that keeps everything running. Walls around the facility are decked with banners that advocate for open communication, honesty, community, positivity and patience. While these sentiments could easily just become empty, yet pleasant words to fill space on the walls, it is apparent that they mean more than that to Professional Plating’s team; rather, they are a mission statement.

Over the past few years, Professional Plating’s leadership has pursued growth in ways it hadn’t considered before, which was largely due to downtime and slower periods during the height of the COVID-19 pandemic. The shop began to experiment with cross training its team members, which has proved to be a great way to keep its team engaged and invested in the work they are doing, while also picking up new skills. Kerry Behnke, Professional Plating’s zinc business team manager, says, “Cross training developed all of these people and made them much more valuable and versatile. It also gave them an opportunity to see areas of the company that maybe they've been interested in working in or transferring to.”

Professional Plating specializes in a variety of finishing processes, including zinc plating, electrocoating and powder coating.

In addition to cross training, Professional Plating has grown its team and built connectedness in its shop by creating several community programs and adopting an online communication platform. The Beekeeper app, which the shop adopted over the last four years, enables the entire shop to communicate with each other via chat and message boards, as well as keep track of progress on different jobs, store documents and more. The app enables people to stay organized and communicate directly, rather than playing a game of telephone, where the story changes the further it gets from the source. Dietz explains that the app “makes it easier for people to know what's going on with each other. We wouldn’t have made it through COVID without it.”

The Applause program enables Professional Plating’s team to recognize each others’ hard work and efforts.

Professional Plating also invests in its team by incentivizing referrals for new hires. Dietz says, “At least 50% of our new hires probably come from a referral from somebody in this company. And we have a referral bonus program, [which means] they have skin in the game.” In addition, Professional Plating enables team members to motivate each other via the monthly Applause program, where team members can thank each other for helping with jobs or recognize each other for their hard work. Reflecting on the team dynamic in the shop, Jessica Moskow, Professional Plating’s powder coating manager, adds, “I think [our team members] know that we’re invested in them, and they feel the small-company feel even though we do have close to 200 team members.”

Trusting in the home-field advantage

With the amount of growth Professional Plating has experienced since opening, Dietz says he is often asked why Professional Plating doesn’t expand and grow its operation into other states, such as Ohio or Indiana. “A lot of people ask, ‘Well, why don't you have another plant in, say, Tennessee?’ Our big answer is that you can't do what we do without the culture of Brillion, Wisconsin,” Dietz says, adding, “You need strong home knowledge, good hearts and good heads to run the product.”

The team is the core of Professional Plating’s story and growth potential, and its shop leadership is keenly aware of this. Prioritizing its people over its process has enabled both facets of the shop to grow organically. “We can find new equipment and invest in new processes,” Dietz says, adding, “but investing in our team and in our people is huge to us.”

Related Content

Conveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read More12 Ways to Improve Your Powder Coating Quality

Often overlooked powder coating procedures that can help you elevate your quality, streamline your operations and improve your profitability.

Read MoreImproving Transfer Efficiencies in Coating Operations

There are many methods for addressing electrostatic grounding in metal painting processes, and Tim Ulshafer from Mueller Electric says the best method for your process is a simple and worthwhile exercise.

Read MoreAdjusting Current and Voltage When Powder Coating

Which manual powder coating gun setting is better to adjust, voltage or current? Jeff Hale of Gema USA discusses when to use different settings on your powder gun to achieve optimal results.

Read MoreRead Next

Episode 42: An Interview with Robin Deal, Hubbard-Hall

Hubbard-Hall wastewater treatment specialist Robin Deal discusses the latest trends in wastewater management.

Read MoreThe 2024 Ford Mustang: All the Colors Available

Although Chevrolet has announced the end of the Camaro and Dodge is offering “Last Call” editions of the Charger and Challenger, the Ford Mustang is launching to its seventh generation.

Read MorePowder Coating 4.0: Smarter, Faster, More Efficient and Connected

New tools reduce cost and waste, lower manufacturing footprint of powder coating operations.

Read More