Gema Adds Service Employees

Gema is adding two ServiceNet technicians to its North American team, Jacob Argyelan and Jerry Croy.

Jacob Argyelan. Photo Credits: Gema USA

Continuing with its commitment to provide high quality and application expertise to its customers, Gema USA Inc. welcomes two employees who are joining its North American service team — Jacob Argyelan and Jerry Croy.

Argyelan formerly worked on the Gema operations team before transitioning to the service team as a ServiceNet technician. In this role, Argyelan is responsible for supervising installations and providing service for Gema customers throughout North America.

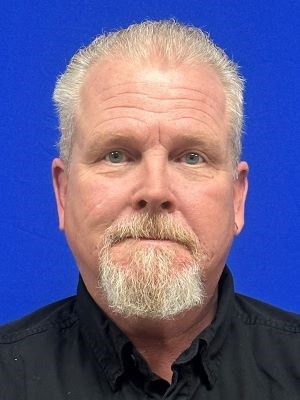

Jerry Croy.

Croy is new to the Gema team but not to the finishing industry. He also joins the company’s service team as a ServiceNet technician. Jerry will be responsible for supervising installations and providing service for Gema customers throughout North America.

Related Content

-

12 Ways to Improve Your Powder Coating Quality

Often overlooked powder coating procedures that can help you elevate your quality, streamline your operations and improve your profitability.

-

Calculating the Cost of Powder Coating

How can you calculate the cost of powder coating a component if you only know its surface area? Powder coating expert Rodger Talbert has the answer.

-

The Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.