A Refresher Course on Ultrasonic Cleaning

A close look at the intricacies of this technology helps with understanding how it is most effectively applied.

Ultrasonic cleaning is a means of preparing surfaces for finishing and processing operations. Sonic energy produced by industrial ultrasonic cleaners quickly removes contaminants from almost any surface that can be safely immersed in a cleaning solution. The challenge is selecting the correct ultrasonic cleaner, along with its accessories, cleaning solution formulations and cleaning procedures, to efficiently accomplish tasks.

Ultrasonic cleaners are fitted with transducers attached to the bottom and/or sides of a tank filled with a cleaning solution. Transducers, powered by generators, cause the tank bottom to serve as a vibrating membrane at frequencies measured in thousands of cycles per second (kilohertz), sending sound waves pulsing through the cleaning solution. These waves produce millions of tiny vacuum-filled bubbles that shoot out a powerful jet of liquid—on the order of 15,000 to 150,000 psi—when imploding. The force of the implosions, called cavitation, lifts contaminants from workpieces.

Featured Content

Ultrasonic cleaners are fitted with transducers attached to the bottom and/or sides of the tank filled with the cleaning solution.

Ultrasonic Cleaner Frequencies

Ultrasonic cleaners are available in several frequencies (37 and 45 kilohertz are ideal for a majority of cleaning tasks). Low frequencies (around 25 kilohertz) produce relatively large cavitation bubbles that implode more violently against surfaces than smaller bubbles produced at higher frequencies. High-frequency cavitation bubbles penetrate and clean small openings and blind holes.

Approximate bubble diameter is calculated by dividing 3.28 by the frequency of the ultrasonic cleaner in Hertz and multiplying by 2. For example, a frequency of 80-kilohertz is equal to 80,000 Hertz, or cycles per second. Divide 3.28 by 80,000 to get 0.000041 meters, or a cavitation bubble radius of about 41 microns. According to this calculation, high-frequency 130-kilohertz cleaners have cavitation bubbles with radiuses at approximately 25 microns.

Ultrasonic cleaner frequencies should be selected based on the part being cleaned. Machined, welded and stamped steel or alloy parts are safely cleaned at lower frequencies, while parts with complex configurations, softer metals and highly polished surfaces should be cleaned at higher frequencies.

If a shop produces or finishes a variety of products, a dual-frequency ultrasonic cleaner, such as Tovatech’s Elmasonic X-tra basic operating system (25 or 45 kilohertz), can be used. Some dual-frequency models can be set to automatically switch frequencies at 30-second intervals.

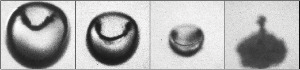

This photomicrograph shows stages of an imploding cavitation bubble.

Tank and Basket Dimensions

Cleaning tank dimensions must be larger than the largest part being cleaned. Parts cleaning baskets, used in the majority of cases, are smaller than the tank’s internal dimensions. Another important consideration is the working depth of the cleaning solution, which is the distance from the inside bottom surface of the basket to the surface of the liquid in a filled tank. Parts being cleaned must be fully immersed in the liquid. Working depth data are available on equipment specification sheets, or can be obtained from the equipment manufacturer.

Some basket upper rims are immersed in the solution while others may not be. Still others may be equipped with rubber-coated feet positioned near the corners of the tank bottom where there is minimal vibration. Fine mesh baskets for small parts can be positioned in beakers or standard baskets. Industrial tanks may be equipped with a bottom rack to support large parts. In these cases, the working depth is the distance from the surface of the rack to the surface of the liquid.

An alternative to baskets or racks is suspending parts in the solution using an overhead support. In such cases, parts coming in contact with the tank’s internal surfaces could lead to equipment damage.

Effective ultrasonic cleaning is dependent on a number of factors, including basket size and tank dimensions.

Operating Modes

Ultrasonic cleaners range from those with a simple on/off switch to highly sophisticated programmable units with features for efficiency and thoroughness. The following variations can provide advantages in certain applications:

Degas mode is engaged to quickly remove cavitation-inhibiting trapped air from fresh cleaning solutions. Units without a degas mode can, instead, operate a cleaner without a load, which can require an excessive amount of time in large-capacity cleaners.

Sweep mode provides a slight variation in ultrasonic frequency to prevent hot spots, or areas of intense cavitation, and dead zones, areas with low or no cavitation. Parts are cleaned more uniformly with sweep mode operation.

Pulse mode provides intermittent spikes of high ultrasonic power to remove stubborn contaminants. Pulse mode also aids the degassing process.

Cleaning efficiency for parts contaminated with coolants and other oily substances increases when the tank is equipped with heaters. Heaters may be thermostatically adjustable to a maximum of 176°F, above which cavitation is inhibited and cleaning efficiency levels off.

Ultrasonic power is a complicated subject, especially with the lack of industry standards regarding how power is expressed. More power (in the same size tank) usually indicates faster and more effective cleaning. However, too much power can damage soft metal surfaces and other delicate items. For cleaning a variety of surfaces, including extremely sensitive items, adjustable power is a useful feature. One example is the dual frequency Elmasonic TI-H and P series, with adjustable power from 10 to 100 percent and 30 to 100 percent, respectively.

Parts agitation during ultrasonic cleaning increases cleaning speed and efficiency. Gentle vertical oscillation of the cleaning basket ±2 centimeters increases cleaning speed by 10 to 20 percent and improves cleaning uniformity in the Elmasonic Flex models.

Ultrasonic Solutions

Cleaning solution chemistry is as important as ultrasonic frequency, power and so on. The most commonly used chemistries fall into three categories—alkaline, acidic and neutral—which are usually supplied as concentrates, so a little goes a long way. When formulated with non-toxic biodegradable ingredients, disposal concerns are eased. Manufacturers can provide dilution and cleaning temperature recommendations. Because most ultrasonic solutions are water-based, rusting may be a concern, so rust inhibitors can be added to the solution.

Cleaning solution volume is also important. Most ultrasonic cleaners have a fill line to specify the maximum solution level. The best cleaning results are performed with a full tank. Another important consideration is the service volume, or the amount of solution needed to accommodate displacement by parts being cleaned when fully immersed. Specifications for service volume are provided in user manuals. Overfilling the tank does not improve efficiency, and under-filling the tank does not intensify cleaning and can damage the tank. The service volume statistic is important because it enables safe solution mixing, degassing and heating when the baskets are empty.

When solutions are maintained, cleaning is more effective. Oily contaminants that float to the surface should be skimmed off and set aside. Spray bars and weirs can handle this function on large tanks. Filtration systems trap contaminants that damage the tank if settled and remain on the bottom, but eventually solutions must be replaced by draining the tank. The tank should be cleaned following user manual instructions.

Rinsing spray stations, rinsing tanks and hot air dryers can be employed for product rinsing and drying, which may be required to remove solution residues prior to painting, plating, anodizing or subsequent finishing steps.

The challenge is selecting the correct ultrasonic cleaner, along with its accessories, cleaning solution formulations and cleaning procedures, to accomplish tasks in the most efficient manner.

Explosion-Proof

Flammable solvents such as acetone, isopropyl alcohol, methyl ethyl ketone and toluene may be required to clean products that require a total absence of residues. In such cases, use explosion-proof ultrasonic cleaners (such as the Electrowave) that comply with OSHA standards and NEC and NFPA guidelines.

These units completely isolate potential spark-generating system electronics from contact with solvent vapors or spilled solvent and are available with tank capacities from less than a gallon to as large as 90 gallons, though they are not equipped with heaters. Because solvents evaporate quickly, operators must maintain a solvent level of more than half the tank capacity or risk damaging transducers.

While Electrowave ultrasonic cleaner equipment is explosion-proof, operating it creates a hazardous area because of cleaning solvent fumes, which must be vented using approved ventilation systems. All electrical equipment, wiring, lighting fixtures, outlets and similar equipment must be rated as intrinsically safe by the National Electric Code, NFPA-70 Articles 500–503. Production machining applications may have various levels of cleaning requirements, and ultrasonic cleaning systems can, generally, meet these needs. Once equipment is in place, plant personnel will gain experience preparing the correct amount of cleaning solution, optimum cleaning solution temperatures and cleaning times for specific applications. Once routines are established, ultrasonic cleaners can be programmed by time, temperature, frequency and other variables, depending on features that the equipment offers.

Robert Sandor is a director at Tovatech. Contact him at 973-913-9734 or tovatech.com.

Tovatech LLC

Originally published in June 2016.

RELATED CONTENT

-

Preparation for Electroplating

What you should know about cleaning and electrocleaning.

-

Powder Coat MDF for an Enviable Finished Product

Cabinet maker says powder coating on wood offers more benefits.

-

Top Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.