Anodized Bright; Anodized Tough

At Fort Wayne Anodizing it's not how it's made; it's how it's made to last...

Many parts benefit from anodizing, particularly hard anodizing, including automotive, military, culinary and medical parts. Even castings benefit from anodizing. Ft. Wayne Anodizing (Ft. Wayne, IN) can make diecastings, pressure casting and sand castings look bright and shiny even without anodizing. What's the secret? Just ask William Branstrator, vice president of operations.

"We developed a process called Metabrite that provides all types of cast parts the same bright, high-luster finish," stated Mr. Branstrator. This proprietary chemical/mechanical process can be used as an alternative to painting, powder coating, buffing and polishing. When combined with anodizing, the resulting parts meet or exceed ASTM and military standards for strength and corrosion resistance. The finish meets a minimum salt spray of 336 hr per ASTM B117.

Featured Content

During the process, contaminants that inhibit anodizing, such as silicone, are brought to the surface. Mechanical finishing is used to remove the contaminants, resulting in bright, shiny parts. As a finishing process it can be a stand-alone final production step; however, it can also undergo additional finishing such as anodizing and chromate conversion coating.

"Usually, an anodized part looks like a piece of charcoal," commented Mr. Branstrator. "With the Metabrite process we can take a diecast or even a sand cast part and anodize it, dye it black and it looks as though it is plastic or painted. Or we can take a sand cast part and a diecast part and make them look enough alike that they can be put together in the same component and you cannot tell the difference."

Still, the toughest coating Ft. Wayne Anodizing (FWA) offers is hard anodizing. "I get a charge out of telling a group of engineers that I can make the surface of aluminum 30-35 points from being as hard as a diamond. You can't cut it with a file. It is about 65-70 Rockwell hard. That is one of the reasons it is used in so many critical applications," Mr. Branstrator claimed.

Hard-coated aluminum is non-conductive to electricity to 2,000v. Because the hard coat anodized aluminum is non-conductive, you can bolt it to brass or steel and not worry about generating a galvanic reaction; therefore, it is qualified for use in salt/corrosive atmospheres. These applications include automotive as well as those you may not consider such as replacement joints for hips and knees. Typical hard-anodized coatings pass the 1,000-hr 5% salt spray test, ASTM B117. If a duplex seal is applied, the coating has been known to resist corrosion in excess of 50,000 hr.

Mr. Branstrator also compared hard-anodized aluminum to stainless steel. It is less expensive than stainless steel. It machines twice as fast and doesn't weigh as much. This saves on shipping costs. "And it is more durable than hard chromium plating because the coating is integral to the part, not just on the part," explained Mr. Branstrator (see Fig. 1).

"Hot brake fluid is one of the most oxidizing fluids known. Human blood is another. These fluids could break down most coatings, but not hard anodizing. That is why most ABS brake systems use hard coat anodizing," he continued. Components for ABS brake systems are some of the highest volume jobs FWA runs on its new multi-million dollar hard coat line.

When FWA installed the fully automated, computerized line from Jessup Engineering, Inc., it did not have a job ready and waiting. "We did not make any ‘widgets' here that we were going to run on it," stated Mr. Branstrator. "We went out and sold the system's capabilities to our customers." And the work came in.

The first job run on the line was for Ford Motor Co. It was a component for a vibration damper on the crankshaft for its 3-liter engine. Ford had opted to use diecast aluminum instead of cast iron to eliminate massive weight on the end of the crankshaft. Although that job is gone due to engineering changes, FWA is now running the vibration damper on the Corvette engine, which is the option engine for the Trans Am (which is in its last year of production).

However, if the Ford engineers return to the original design, FWA would have no problem running it. The advanced computerized program allows pre-programmed job sequences, written up by FWA based on the alloy, surface area to be finished and specifications. The automated system will control tank temperatures and the drying system. These programmed specifications are stored and may be recalled for future production needs, enabling FWA to maintain exact tolerances . . . even years later! This automation eliminates human handling once the components are racked, resulting in increased capabilities and greater efficiency in both high- and low-volume production.

Microhardness is nearly independent of coating thickness, up to 1.5 mils. An aluminum coating with a hardness value of 450VPN exhibits the same wear characteristics as tool steel that has twice the microhardness of aluminum hard coatings.

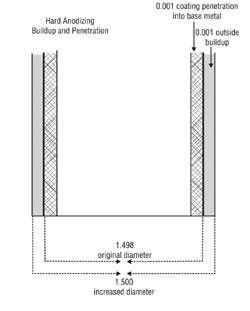

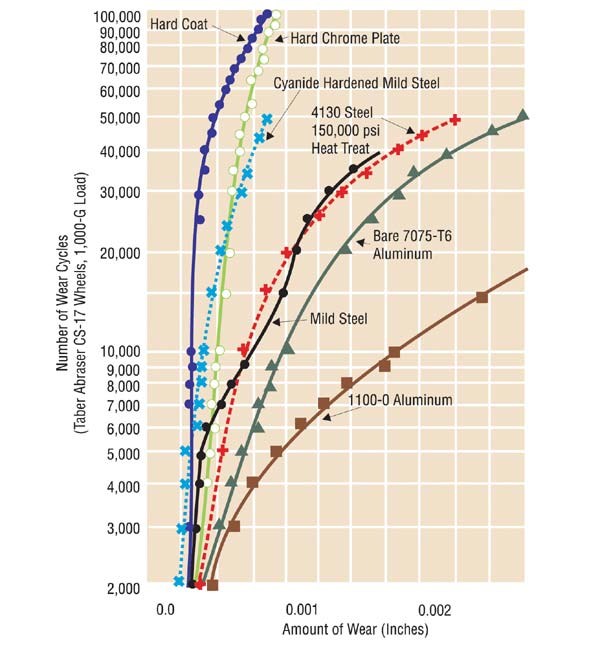

Wear Resistance. Wear resistance is measured by the weight of an abrasive required for a controlled pressure jet to blast through the coating. Hard coatings exhibit a wear resistance greater than 10 times that of ordinary anodized aluminum. In the standard Taber abrasion test, hard-anodized aluminum exhibited only half the wear that cyanide case hardened steel showed after 50,000 cycles. When the test was extended to 100,000 cycles, the surfaces of 4130 steel, mild steel and chrome hardened steel showed greater wear than hard-anodized aluminum (see Fig. 2).Appearance. As coating thickness increases, color varies from colorless to light brown on pure aluminum at 1-5 mils thickness. Alloys vary in color depending on alloy composition, usually ranging from tan to jet-black for 1-3 mils thickness.

Uniformity. In the hard anodizing process, the coating follows the contour of the part. Hard coat builds up in holes to the same thickness as on the part's exterior. This allows for precise control of very close tolerances in critical applications.

Surface roughness, which increases depending on individual applications, alloy and coating thickness can be honed smooth. Due to excellent throwing power of the process, it can effectively coat unusually shaped parts.

Heat Resistance. The inert nature of the anodic coating provides excellent heat resistance. Hard-anodized parts show no effect after short exposure to temperatures as high as 2,000C. Although coating thickness is not a major factor in heat resistance, exposure to direct flame has shown that thicker coatings provide a longer life for the exposed part.

Thermal Properties. Hard-anodized coatings exhibit low thermal conductivity and expansion. Pistons for internal combustion engines are hard anodized to minimize the amount of thermal expansion in relation to possible thermal expansion of the engine block.

Electrical Properties. Aluminum oxide and its alloys can be used as electrical insulators. The high temperature stability of the coating permits operation up to 500C. Anodic coatings typically exhibit a voltage breakdown of 2,000-3,000 v/mil, a dielectric constant of 7.4-7.6 and resistivity from 1014 ohm cm to 200C. This resistivity is of the same order of magnitude as glass and porcelain.

These properties make the coating excellent insulation for mounting electronic components.

Lubricity. Any hard-anodized surface has a high degree of lubricity. In certain applications, hard-anodized surfaces can run against other hard-anodized surfaces without lubrication. Impregnated with solid lubricants such as PTFE, hard-anodized aluminum surfaces have an even lower coefficient of friction.

FWA offers vacuum impregnation of diecastings and sand castings. Vacuum impregnation is a way of sealing the porosity in the casting, since untreated porosity can lead to fluid and gas leaks, plating defects, reduced machine tool life and a high scrap ratio.

During vacuum impregnation, a vacuum system is used to draw air and volatile materials from the castings' porosity. Once the vacuum is drawn, a liquid sealant is drawn into the pores of the casting, creating an airtight seal. Impregnation is the fastest and most effective method of eliminating porosity and interior corrosion in metal castings, forgings, powdered metal parts and plastics. FWA claims it can recover up to 95% of rejects using this method. The company has both dry (vacuum and pressure) and wet (vacuum only) processes.

In addition to vacuum impregnation and hard coat anodizing, FWA offers sulfuric acid anodizing, dying, chromate conversion coating and its new Metabrite process. And the company is always growing. "When I started here in 1974, we had 4 employees, maybe 3 customers and did about $150,000 in business. In 2000, we did $6,000,000 worth of business with 656 different customers across the United States," noted Mr. Branstrator. "We are an ISO 9002 certified job shop. We handle small runs; we handle jobs with millions of pieces. If it needs anodizing, we can do it."

Each customer of Fort Wayne Anodizing, large or small, is unique and poses its own challenge. The company welcomes the challenge of meeting each customer's requirements with on-time delivery and competitive prices. An on-line tracking system is integrated throughout the plant to provide instant product traceability. Using this system, the company can schedule and consistently monitor the status of production to meet the demanding deadlines of its customers, including the automotive manufacturers.

To learn more visit Jessup Engineering, Inc. and Process Technology.

RELATED CONTENT

-

Test Methods For Evaluating Anodized Aluminum

Benefits of anodizing include durability, color stability, ease of maintenance, aesthetics, cost of initial finish and the fact that it is a safe and healthy process. Maximizing these benefits to produce a high–performance aluminum finish can be accomplished by incorporating test procedures in the manufacturing process.

-

Understanding Corrosion and Salt Spray

How it’s produced, NSS testing and how to get the best results possible.

-

Aluminum Anodizing

Types of anodizing, processes, equipment selection and tank construction.