February 2013 ISSUE

CCAI Presents "Basics of Powder Coating" in Spanish on April 16 in Miami

Conceptos Básicos de Pintura en Polvo en Español, to be held on Tuesday, April 16 at the American Welding Society Headquarters Conference Center in Miami, FL.

#basics #curing #masking

FEATURES

Parts CleaningBASF building new automotive coatings plant in Shanghai

New production facility is scheduled to commence operation in early 2014; complements the company’s existing plant in Shanghai, which has been operating for more than 15 years.Parts Cleaning

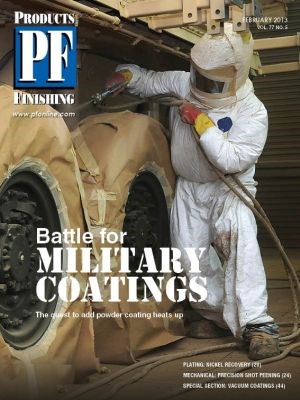

Battle for CARC Powder Coating

Sherwin-Williams and PPG were awarded research grants by the Department of Defense in June 2012 to develop a zero-volatile organic compound, zero-hazardous air pollutant exterior topcoat to replace the military’s current generation of liquid-applied chemical agent resistant coatings (CARC) by 2015.

Bringing You the Future of Coatings with PVD

Products Finishing partners with Society of Vacuum Coaters

Powder Coating

CCAI Presents "Basics of Powder Coating" in Spanish on April 16 in Miami

Conceptos Básicos de Pintura en Polvo en Español, to be held on Tuesday, April 16 at the American Welding Society Headquarters Conference Center in Miami, FL.Powder Coating

CCAI SoCal Chapter Partners with Marines on 'Toys for Tots' Event

Nearly 190 toys collected to help disadvantaged kidsEmployment Inches Forward, Factory Production Rises

NASF Economist Ken Mayland says total nonfarm payrolls rose 155,000 for December, according to the Bureau of Labor Statistics; the two previous months were revised a net 14,000 higher as the unemployment rate for the last month of the year stood at 7.8 percent.Anodizing

Haviland Announces 100% Employee Ownership

Prior to this sale, Haviland Enterprises was owned 54 percent by the Haviland family and 46 percent by Haviland employees.Mechanical Finishing

Microabrasive Precision Shot Peening

Precision shot peening brings an entirely new concept to the field of microabrasive blasting, and it is complementary to its larger cousin. Using glass bead media, several companies have been shot peening for years with microabrasive blasting technology.Electroplating

NASF's AESF Foundation Awards Scholarship

Sudarshan Narayanan is currently focusing on transparent conductors for optoelectronic applications and is expecting to complete his doctorate in 2013Liquid Coating

New Chromium Electroplating Housekeeping Requirements

Alert for Platers: Your Deadline is March 19, 2013 as EPA finalized the residual risk and technology review for the national emission standards for hazardous air pollutants (NESHAP) for hard and decorative chromium electroplating and chromium anodizing tanks under 40 CFR Part 63

Anodizing

New USGA Stimpmeter Shines in Anodized Blue

Day Tool & Mfg. in Whitehouse, NJ and B&M Finishers in Kenilworth, NJ work to get the blue anodized look just right.Electroplating

Nickel Saved is Nickel Earned

Those in the plating industry are continually working on the development of a process to recover valuable nickel from spent electroless nickel solutions. Now there is a two-stage method to do just that.Powder Coating

Painting Over Powder Coating

Can powder coating be used on top of another coating?Electroplating

Plating Q&A: Low Stress Nickel Deposit

Plating expert Art Kushner answers a question about parts that specify a “low stress” nickel deposit, and whether there are numerical ranges for high- and low- stress nickel deposits.Parts Cleaning

Powder Coat Q&A: A Good System Gone Bad

Rodger Tallbert answers a question about a problem with light coating on an automotive product, where the coater is not getting the kind of coverage they got when the system was new.Powder Coating

PPG Also Wins $1.5 Million Through DoD’s SERDP

PPG will work with ARL to develop a powder topcoat that will meet military standards for ultraviolet durability, matte finish and resistance to chemical agents.

Progress in Replacing Decorative Electroplating Chrome Coatings on Plastics with Physical Vapor Deposition Coatings

Decorative electroplated chrome coatings on plastics have been produced for decades. For environmental reasons, there has been a shift away from hexavalent chrome (Cr6) to trivalent chrome (Cr3) with increased investments towards elemental chrome PVD coatings to maintain the true chrome appearance.Mechanical Finishing

Taking the (Oxide) Edge Off

Metal fabricators that laser-cut with oxygen take steps to prepare parts better for powder coating.Vacuum Deposition and Coating Options

This overview takes a look at vacuum deposition technologies as processes that may be used to create coatings that can be substituted for or enhances the properties of electroplated coatings. Initially, this work discusses trends in metal finishing and environmental regulation.Why Vacuum Coating?

There is common interest among platers and vacuum coaters.

Electroplating