January 2011 ISSUE

7 Changes to Reduce Spray Costs Immediately

Jon Barber of Spraying Systems Co. in Wheaton, IL, says that the sluggish economy often causes manufacturers to convert their “cost management” programs into “cost reduction” programs.But Barber warns that cutting costs can have a negative impact on products and process quality, and can actually lead to higher scrap rates, costlier product recalls and unhappy customers.

#economics

FEATURES

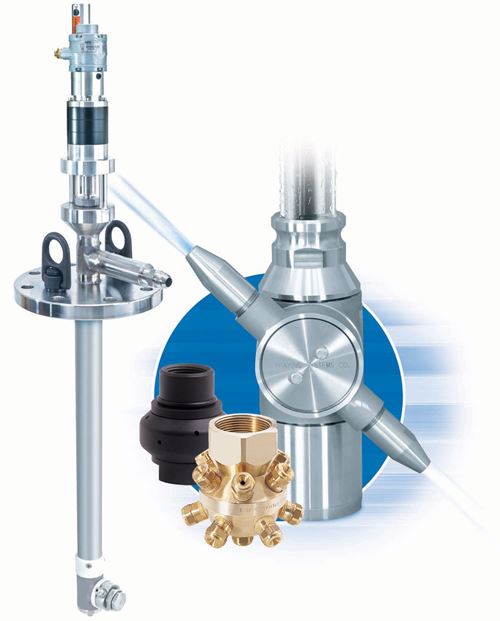

Parts Cleaning7 Changes to Reduce Spray Costs Immediately

Jon Barber of Spraying Systems Co. in Wheaton, IL, says that the sluggish economy often causes manufacturers to convert their “cost management” programs into “cost reduction” programs.But Barber warns that cutting costs can have a negative impact on products and process quality, and can actually lead to higher scrap rates, costlier product recalls and unhappy customers.

Electroplating

Electroless Nickel Solution Adds Chemical Marker

The day may have arrived when finishers can now grab a small electronic device and test to see if the rejects coming back to them were actually finished in their shop, and not, say, in the customer’s second-source finisher.

Parts Cleaning

Questions and Answers for Painting Anodized Aluminum

We paint parts made of anodized aluminum. Suddenly, we are having a problem with paint adhesion. Is this an adhesion problem? What are the pros and cons of painting anodized aluminum?Electroplating

The Challenge of Electroplating Cast Iron Components

Manufacturing from cast materials is a cost-effective method to form complex shaped components.

Powder Coating

Seeing Inside Nooks and Crannies for Auto Corrosion Protection

Fischer Technologies (Windsor, CT), a manufacturer of coating thickness, material testing and material analysis instrumentation, has introduced a new, non-destructive flexible probe which they say can get inside normally inaccessible cavities to get measurements.