February 2012 ISSUE

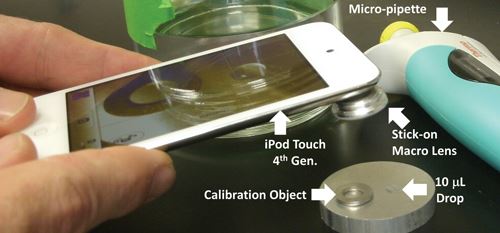

Just How Clean Is Clean?

Most finishing consultants have lost count of the number of times that inadequate cleaning and pretreatment was the cause of defective painting or plating. Skip plating, blistering, delamination—these are just some of the commonly found defects caused by poor cleaning.

FEATURES

ElectrocoatingAdding E-Coat to an Existing Powder Coating Line

If sales for your finishing business have been declining, you may need to consider adding a new coating line to bring in new business. An option may be to add an electrocoat system to your current powder line to increase your coating capabilities.

Electroplating

Alternative Bath Control Practice

Your finishing operations can improve quality and lower cost by a change from the standard process control practice to add material following bath analysisAnodizing

Ask An Expert: Blistering of Anodic Coating on 7075 Alloy

Q. We are facing a blister problem on 7075 alloy inside the bore diameter of our cylinder base. We noticed that this problem is occurring during dyeing process and not after hard anodizing. Can you please advise us what could be the reason? S.C.Powder Coating

Bernard Downey, Coating Pioneer, Passes Away at 88

Founder and president of B.L. Downey Co., a 325,000sf2 facility that specialized in e-coat and powder coating.Mechanical Finishing

Deburring Change Earns 'Find-It Fix-It Challenge' Award

Award recognizes and rewards simple and effective workplace solutions that result in increased productivity, improved worker morale, and fewer workplace injuries and illnesses.Electroplating

Electronic Precision Specialties Wins 'Metal Finishing Model Shop Award'

The California/EPA Department of Toxic Substances and Control has recognized Electronic Precision Specialties, Inc., with the "Metal Finishing Model Shop Award," only the fourth shop to receive the award.Liquid Coating

Just How Clean Is Clean?

Most finishing consultants have lost count of the number of times that inadequate cleaning and pretreatment was the cause of defective painting or plating. Skip plating, blistering, delamination—these are just some of the commonly found defects caused by poor cleaning.Liquid Coating

Military “STARs” Are Born With Paint Facilities

The Yermo Annex Marine Corps. Logistics Base in California and the Corpus Christi Army Depot Aviation Center in Texas have acquired new systems to help train and enhance employees’ painting abilities.Electroplating

NASF Connecticut Chapter Holding Supplier Exhibition March 6

All proceeds at the event are used to sponsor the Connecticut Branch’s College Scholarship, which is given to a child of a Connecticut Branch member.Powder Coating

Navy Is Full Steam Ahead On Powder Coating

With the military increasing its use of powder-based coatings to cover vehicles, equipment and ships—the Army has recently announced that it will allow the use of powder coatings in its CARC coverings that are normally e-coated—more assets are getting the powder coating treatment than ever before, much to the joy of the powder manufacturers.

Electroplating

NEWS: Water Company Finds Source of Hex Chrome: Itself

The Louisville Water Co., which serves about 850,000 residents with water in the Kentucky region, found the source of its hexavalent chromium issues: its own equipment.Parts Cleaning

Solvon Meeting Military Inspection

Poly Systems in Deer Park, NY has released an updated version of its Solvon FB cleaning solvent blends consisting of a high-purity, patented combination of n-propyl bromide and pentafluorobutane.

Liquid Coating

The EPA’s Common Sense Initiative and Its Legacy on the Finishing Industry

The Common Sense Initiative was the centerpiece of the U.S. Environmental Protection Agency’s much-touted regulatory reinvention in 1994. Called a “bold experiment,” the EPA developed the Common Sense Initiative to address claims that its regulatory process had become burdensome, inefficient and costly.Liquid Coating

A “Bizarre” Approach: Using Moisture to Cure CARC Coatings

When veteran inventors Mike Bunnell and Daryl Bruischat put their minds together to build a better mousetrap for the drying and curing of waterborne CARC paints, they both hoped to come up with a system that might change the industry somewhat.