NASF Nov. 2010 ISSUE

Validation of New Generation Tooling Concept for Electroplating of Copper on Printed Circuit Boards

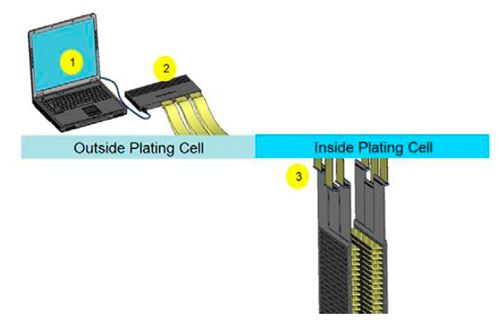

A dynamically software controlled electroplating tooling concept has been developed to compensate the pattern dependence of the deposited layer thickness on different substrates. In this paper a validation of this new tooling concept on industry relevant printed circuit boards is presented. Simulations are compared with experimental results as obtained in a prototype electroplating cell. A quantitative improvement of the plating thickness uniformity between a standard electroplating cell and the advanced tooling approach is given. The influence of the conductivity of the electrolyte on the deposit distribution is studied and indicates a way to obtain a significant improvement in uniformity.

#electronics

FEATURES

Electroplating: An Alternative for Producing Low Magnetic Loss Amorphous Alloys

In recent years, Hydro-Québec’s Research Institute has developed, through technological innovation, a program to improve energy efficiency in the generation, transmission and distribution of energy.Functional Trivalent Chromium Electroplating

This paper will discuss recent research work on the development of a functional trivalent chromium plating process from a single, simple-to-control trivalent-based electrolyte to replace hexavalent chromium plating. Hexavalent chromium plating has been used for many years to provide hard, durable coatings with excellent wear and corrosion resistance properties. However, hexavalent chromium baths have come under increasing scrutiny due to the toxic nature of the bath, effects on the environment and worker health. In this work, we are updating accomplishments to achieve properties comparable to existing hexavalent chromium plating for functional applications. Work on achieving desirable thickness, uniformity, adhesion, porosity and corrosion resistance, as well as other material properties, will be discussed.Tanks and Liners: Is Conventional Wisdom or Reliance on Internet-Based Answers Putting your Company at Risk?

Finishing companies face an array of unprecedented challenges. Decision-making is affected by these pressures. Conventional wisdom and/or the reliance on internet-based answers can lead to procurements that create unnecessary downtime, safety risks and loss. Factors compounding the pain of inadequate options and poor choices are aging plants and equipment, a shrinking manufacturing workforce and legal/policy/regulatory costs. Topics covered in this article include: (1) an overview of tanks and liners, (2) the true costs of downtime, (3) results from a recent tank and liner market survey, (4) the plastic paradox (including fires), (5) spark testing and leak monitoring technologies, (6) drop-ins, (7) what to look for from a supplier and (8) new advancements.Validation of New Generation Tooling Concept for Electroplating of Copper on Printed Circuit Boards

A dynamically software controlled electroplating tooling concept has been developed to compensate the pattern dependence of the deposited layer thickness on different substrates. In this paper a validation of this new tooling concept on industry relevant printed circuit boards is presented. Simulations are compared with experimental results as obtained in a prototype electroplating cell. A quantitative improvement of the plating thickness uniformity between a standard electroplating cell and the advanced tooling approach is given. The influence of the conductivity of the electrolyte on the deposit distribution is studied and indicates a way to obtain a significant improvement in uniformity.Michael Siegmund, President, NASF: Message from the President