Becoming an Approved Aerospace Anodize Supplier

Fabrication of aerospace structure requires rigorous standards due to the high cost of rework and the severe consequences of in-flight failure. To become a supplier for aerospace anodize, an approval process which is not readily understood must be followed.

#aerospace

By W. J. Fullen, Boeing Company; Gary M. Kriesch, Walgren Company; Earl W. Turns, Earl W. Turns & Associates

Featured Content

Presented at the 19th Annual International Anodizing Conference & Exposition, October 5-7, 2010, Montreal, Quebec, Canada. For more information, please visit Anodizing.org

Fabrication of aerospace structure requires rigorous standards due to the high cost of rework and the severe consequences of in-flight failure. To become a supplier for aerospace anodize, an approval process which is not readily understood must be followed. The purpose of this article is to provide clarification of the steps needed to become an approved aerospace anodizer for the most prevalent anodize processes in the aerospace industry: Chromic acid anodizing (CAA); Sulfuric Acid Anodizing (SAA); Thin Film Sulfuric Acid Anodize (TFSAA); Phosphoric Acid Anodizing (PAA); and Boric Acid – Sulfuric Acid Anodizing (BSAA).

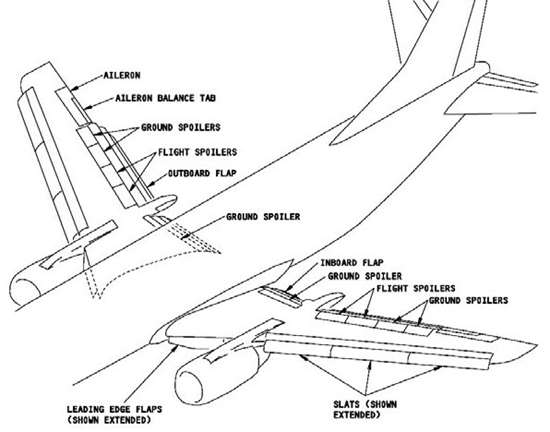

As summarized by Juhl1, most aerospace anodizing is performed to improve the adhesion of paint, adhesives and provide corrosion protection (i.e. CAA, BSAA, and TFSAA) and to provide abrasion resistance (i.e. SAA). PAA is a process developed by the Boeing Company which is used to prepare aluminum surfaces for structural adhesive bonding (i.e. flight control surface applications). Adhesive primer is applied to unsealed PAA, and bonding is then performed using filmed adhesive. The bonds formed are environmentally durable and robust, as evidenced through wide spread application and continued use for over four decades. Figure 1 shows the locations of areas where structural adhesive bonding with PAA is performed.

The first realization that a prospective anodize supplier needs to understand is that the procurement group of Aerospace OEM’s (original equipment manufacturers) do not purchase anodize services, they purchase finished parts. Thus a prospective anodize supplier is best served by identifying aerospace part suppliers who either do not have in-house anodize capability, do not have the tanks large enough for a specific part size, or have the anodize process as their production bottleneck.

Aerospace part suppliers need anodize suppliers who are capable of applying primer. Since the anodize structure has a porous morphology (Figure 2), transporting a freshly anodized surface outside of controlled conditions is not a practicality that is ever employed. And, since aerospace primers are typically chromated epoxy primers, suppliers must be knowledgeable of and prepared to comply with the local environmental regulations.

And, since aerospace primers are typically chromated epoxy primers, suppliers must be knowledgeable of and prepared to comply with the local environmental regulations (Figure 3).

After aligning with an Aerospace part supplier, the next step is to contact the Aerospace OEM procurement group or focal for the purpose of presenting how this new prospective alliance can add benefit to the OEM supply chain. Typically, OEM’s are seeking suppliers of parts that: a) cost less, b) have a quicker “turn time”, c) have better quality, and d) no one else can provide.

Suppliers seeking opportunities for aerospace anodizing should also be prepared to meet applicable engineering and manufacturing requirements that are often fully described in the OEM’s process specifications. Consequently, the candidate anodizer should study the process specifications of interest and take note of all requirements pertaining to: 1) Facilities Control, 2) Manufacturing Control, 3) Maintenance Control, and 4) Test Methods. These requirements are covered in greater detail in a paper to be presented during the Focus Session.

The next major realization that a prospective anodize supplier needs to understand is that Nadcap (National Aerospace and Defense Contractors Accreditation Program) accreditation is a required element to be considered as a candidate for aerospace anodizing. Nadcap is an independent organization comprised of technical experts from prime contractors, suppliers and the government. The Nadcap program gives accreditation for Chemical Processing, of which anodizing is a part. The PRI (Performance Review Institute) administers the Nadcap program and has a searchable website that provides details on how to achieve accreditation:

http://www.pri-network.org/Nadcap/aboutNadcap/process.htm

Essentially, PRI will schedule an audit and assign an approved auditor. The audit will be conducted per an industry agreed standard method and checklist. When working towards Nadcap accreditation, one of the most important first steps is to perform a thorough self audit per the PRI available checklist. There are many items that are covered, however, the ten most identified Findings typically relate to aspects of:

- 1) Training, Qualification and Evaluation of Personnel

- 2) Test and Data Review

- 3) Test Failure, Replacement, Testing and Retesting

- 4) Statistical Methods

- 5) Job Documentation

- 6) Solution Control

- 7) Oven Control

- 8) Thickness Verification

- 9) Equipment Maintenance

- 10) Continuous Process Improvement Plan

Identified non-conformity issues will be clearly communicated verbally and by a report. PRI administers the closeout of the non-conformance items and then provides a report of the completed audit package to the chemical processing task group. It is this group that then reviews the report and collectively votes on a candidate supplier’s acceptability for approval. The Nadcap process is not easy and does require supplier funding. For this reason, it is re-emphasized that a potential anodize supplier be aligned with an aerospace part supplier and the OEM Procurement group before pursuing a Nadcap approval.

Once Nadcap chemical processing accreditation has been achieved, the next step is to submit a request, through the OEM procurement group/focal for a “Supplier Quality” audit to be performed. If the request is accepted, the Procurement focal assigns the audit request to the applicable OEM Division and a Supplier Quality focal is assigned the task. At this point, the supplier can coordinate logistic details with the Supplier Quality focal directly such as when the on-site visit will occur. However, any cost related inquiries need to be coordinated with the Procurement focal directly.

The on-site visit usually consists of a representative from the OEM Supplier Quality group and from the OEM Engineering group. These on-site visits have a pre-arranged agenda dependent on the specific processes involved. Generally, a process specific checklist is employed and is based on the Engineering, Facility, and Quality requirements specific to the applicable process specifications. The main process specification numbers of most interest at Boeing are:

- BAC5632 - Boric Acid – Sulfuric Acid Anodizing (BSAA)

- BAC5019 - Chromic acid anodizing (CAA)

- BAC5555 - Phosphoric Acid Anodizing (PAA)

- BAC5022 - Sulfuric Acid Anodizing (SAA)

At Bell Helicopter (Textron), the process specification of most interest is:

- BPS 4555 – Thin Film Sulfuric Acid Anodizing (TFSAA)

At Lockheed (Ft Worth) where the F-16 and F-35 are assembled, the process specifications used are: FPS-3090 and FPS-8628 T IIB respectively.

The conclusion of the on-site visit is summarized in a “de-brief” meeting where action items are presented to the supplier. These action items are assigned to responsible Supplier individuals along with estimated completion dates (ECD). Resolution and status of action items may require follow-on conferences but are not typically conducted on-site. Once all action items have been successfully resolved, the OEM Supplier Quality focal informs the OEM Procurement focal that the candidate Supplier can be listed as an approved supplier for the target process. The OEM Procurement focal then electronically lists the Supplier details into a database. At Boeing, this electronic database is known as D1-4426 (Approved Process Sources). Being on this list, for the target process, then opens this supplier to be engaged by any OEM procurement person.

An example scenario might unfold as follows. An anodize house has a desire to be a potential supplier to the aerospace industry. They take stock of their current process capability, functional equipment potential, existing supply chain proficiency and laboratory competence. The Sales or Marketing departments use their existing industry contacts and identify a machining part supplier or an assembly fabricator. These preliminary inter-company discussions help forge how a business case might exist before significant resources and capital are expended to gear up to be an aerospace anodizer. Once this anodizer-part manufacturer is established the OEM procurement organization is contacted and they are convinced how this new supplier relationship creates a set of benefits that are advantageous and sustainable. The OEM procurement focal engages a group on Engineers that work closely with new and existing suppliers. If the anodizer is not well known to the OEM, then an OEM Field Engineer schedules a visit the anodize house facility to perform a capability assessment. Once a the OEM procurement group receives a favorable capability assessment from the OEM Field Engineer, the anodizer prepares for NADCAP accreditation. Study of the NADCAP criteria and performing an internal audit using a NADCAP website downloadable checklist is performed. Based on the internal audit results, corrective action is implemented. Corrective action based on internal audits is very possibly an iterative process. Having performed sufficient homework, preparation, a NADCAP audit is scheduled. NADCAP accreditation is achieved after formal corrective actions are resolved. With accreditation in hand, the OEM procurement group is contacted again and an OEM audit request is submitted. The OEM Supplier Quality group schedules a time to be on-site and provide rigorous assessment of ability to perform the anodize and priming processes of interest. The OEM Supplier Quality team conducts a “debrief” meeting (at the end of the week) to discuss required action items. Over the agreed upon time period each action item is resolved upon which the new anodizer can be listed on the approved supplier list (e.g. Boeing D1-4426, Bell QPS 101, and Lockheed QCS-001). Now (at long last) the part suppliers can use the newly listed anodizer at will.

Summarily, the basic steps needed to become an approved aerospace anodizer are:

- 1) Realize that aerospace anodize and aerospace painting go together

- 2) Align with a machining part supplier or assembly fabricator

- 3) Align with OEM procurement group/focal (discuss tentative work packages, e.g. part numbers)

- 4) If needed OEM Supplier Quality group may perform a Capability Assessment

- 5) Prepare for applicable NADCAP accreditation

- 6) Obtain NADCAP accreditation

- 7) Submit audit request to OEM

- 8) Coordinate with OEM Supplier Quality group

- 9) Resolve any resulting action items

- 10) Receive applicable listing (e.g. Boeing D1-4426)

- 11) Coordinate with OEM Procurement on formal bid process

Summary

Becoming an approved aerospace anodizer is an arduous task that requires a dedicated and talented staff to achieve this goal. However, the rewards are more than just a business scope expansion. Having gone through the approval process an approved aerospace anodizer will be challenged and undoubtedly make improvements to one, some or all of: 1) operations, 2) quality systems and 3) facility. The aerospace industry appears to be on a near term upswing and may provide new anodize suppliers opportunities that are very exciting with significant abilities for growth.

REFERENCES

1) Juhl, Anne Deacon, Metal Finishing, February 2010, Vol. 108, No.2; Overview of Anodizing in the Aerospace Industry.

2) Pate, Kevin D. Applications of Adhesives in Aerospace; Adhesion Science and Engineering, Vol. 2: Surface Science, Chemistry and Applications”

RELATED CONTENT

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.

-

Smut and Desmutting

Question: I am new to this industry and have heard about smut and desmutting operations.

-

Fixing Corrosion Between Anodized Aluminum and Steel

Anne Deacon Juhl, Ph.D., with AluConsult, says Galvanic corrosion is due to an electrical contact with a more noble metal or a nonmetallic conductor in a conductive environment.