Coating Really Small Parts - A Finisher's Perspective

Until recently, finishers did not have many options when coating small parts. But, MetoKote, an organic finishing job shop, has developed a conformal coating process as an alternative to bulk coating systems that can be used to coat small parts and metal powders...

Most of the finishers and suppliers in the organic finishing industry have focused on the coating of medium-sized parts. For good reason too—that's traditionally been where the money is. Even in the various trade magazines little is written about coating small to almost impossible-to-see parts.

Until recently, MetoKote had focused its development efforts on powder coating, electrocoating and liquid spray coating where parts are loaded onto automated coating lines. These processes are cost effective for medium to large parts. However, as parts become smaller, the ratio of coating cost to total part cost increases until coating them often becomes economically prohibitive.

Featured Content

So, what do you do if you need an economical, polymeric coating for a part smaller than a shirt button? How about a metal powder? Well, at MetoKote, we took it upon ourselves to develop just such a process, known as the MicroPart coating process.

Microcoating vs. Bulk Coating

There are several bulk organic coating systems available that serve the small parts market. Most of these systems involve dipping parts into a container filled with the coating and then rapidly spinning the container to remove the excess coating. This process is commonly known as dip-spin coating. While this coating system has its advantages, there are some disadvantages: small holes are covered by the cured coating; coating buildup in areas, such as inside corners, where the coating can't be spun off; and the coating flows away from the edges of the part.

However, the microcoating process that we use at MetoKote is a conformal coating system. What is a conformal coating process? Conformal coating is a process that allows the coating to "conform" closely to the shape of the part. It maintains the part's dimensional uniformity whether you are coating an edge or inside a blind hole. The conformal coating process fluidizes the parts to be coated in air so that all surfaces are coated with micron-sized droplets of the coating. A variety of coating materials can used in this process, including epoxies, polyesters, polyvinyl chlorides, polyurethanes, acrylics and alkyds, just to name a few.

The benefits of this process include the precise control of coating thickness, without excessive buildup in recessed areas, and the application of several different coatings, one on top of the other, during the same process. These benefits are possible because the micron-sized droplets of the coating begin to setup as soon as they impinge the surface of the part, minimizing migration. Statistically, all surfaces see the same number of droplets, and, therefore, the same coating thickness. To apply multiple coatings, you simply atomize the next coating after applying the first coating to the desired thickness.

MicroPart Process

The MicroPart coating process is able to apply multiple coatings on a single small part or particle because the object to be coated is fluidized in air and passed through a coating chamber at high velocity. The coating is atomized to micron-sized droplets and sprayed so that these droplets collide in the coating chamber with the parts being coated. As the parts continue through the coating chamber, the coating forms a dry film through solvent evaporation or a crosslinking mechanism. The fluidization air velocity, coating rate, coating droplet size and temperature are optimized so that the parts are kept separate until the coating is in a "non-tacky" state. Film build is achieved by passing the parts through the coating chamber as many times as necessary. Once the desired coating thickness is achieved, the next coating can be applied.

MicroPart Coating Capabilities

The coating process we developed is capable of coating parts ranging in size from approximately 0.5 inch (depending on part geometry) down to metal powders only 0.0002 inch (5 microns) in diameter. Coatings can be applied at less than one micron to several hundred microns without excessive buildup, even in blind holes. A unique advantage of this coating process is the ability to apply multiple thin coatings in discrete layers during the same process, which reduces process time and labor and ultimately saves money.

A multilayered coating provides properties impossible to duplicate with a single coating formulation. This is true because each layer in a multilayered coating can provide unique benefits. However, a part with a single coating that needs to serve two or more functions requires the blending of these coatings, assuming they are compatible. When materials are blended together, they generally lose the properties that made them desirable in the first place. The resulting coating is a compromise between the two independent coatings. For instance, if you wanted a coating that would protect a part from corrosion and surface abrasion, you might mix a good corrosion resistant material with a good lubricant. But, as soon as these materials are mixed the resulting coating is not as corrosion resistant (small amounts can have dramatic effects) or as abrasion resistant as the original materials. But, with a microcoating process, you can apply the coating with corrosion protection as the first coating and the coating with abrasion resistance as the second, preserving the optimal properties of both materials.

Microcoating Small Parts

Many parts that are difficult to coat using conventional bulk coating methods can be coated using a microcoating process. The part in the picture (see photo) requires a coating that must protect the part from corrosion and reduce its surface friction. During the process, the coating is applied to the part as a thin uniform film without covering the hole. Economic constraints require that the coating on this part be applied at an extremely low cost. A microcoating process successfully meets these coating objectives.

Microcoating Metal Powders

A microcoating process can also be used to apply uniform, thin coatings to metal powders. Some coating applications improve the flow and compressibility characteristics of metal powders, which ultimately improve manufacturing. Other applications change the surface morphology to improve physical characteristics or simply add a binder to hold the powdered metal together when pressed into a part.

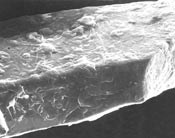

The picture to the left shows a scanning electron micrograph at 1,500 times magnification of a neodymium-iron-boron particle coated using the MicroPart process. This particle was coated using four thin coatings in layers to obtain performance objectives not possible with a single coating formulation.

Ultimately, these coated particles are pressed into high-energy bonded magnets. The goal of the coating was to produce a press-ready powder that would protect the finished magnets from corrosion, serve as a binder to hold the magnets together once they were formed, improve the finished magnet's performance by increasing the powder's compressibility and improve manufacturing by increasing the powder's flow characteristics. The first coating applied is a thermoplastic barrier coating to protect each particle from corrosion. The second coating, applied over the barrier coating, is an epoxy that is crosslinked after the powder is pressed into its final form. The third coating contains a lubricant to improve the powder's compressibility. The final coating is a film-forming polymer that improves the powder's flow characteristics, yet is readily broken during the manufacturer's pressing operation to allow the epoxy binder to flow and crosslink during the final forming operation.

Economics

In addition to providing many unique opportunities for the application of coatings to small parts, this process often enables these parts to be coated for a fraction of the cost of conventional methods. This is due to the ability of the process to handle large volumes of small parts or particles and to coat them at almost 100% transfer efficiency. Consequently, small parts or particles are coated economically and consistently. This process and others currently being developed at MetoKote provide us coating options for small parts or particles not previously available.

To learn more visit PPG Coatings Services.