Custom Masking Helps Hixson Soar

Boosts productivity at aerospace finishing shop

#masking #aerospace

Hixson Metal Finishing Inc. (Newport Beach, CA) is a full-service anodizing, plating and painting company known for its ability to produce high-quality parts with rapid turnaround times. The company specializes in coating of parts for the aerospace and other high-precision industries. Customers include giant aerospace OEMs as well as their tier suppliers.

The ability to provide a wide array of process capabilities is one advantage Hixson has over some of its competitors. The company offers “one-stop shopping” for a variety of anodizing, plating, painting and nondestructive testing processes.

Featured Content

“At any one time, we’ve got 460 to 600 active jobs in our shop,” says CEO Doug Greene. “Many of these are parts we haven’t even seen until they show up at our door.”

According to Greene, Hixson is anything but immune to the decreasing lead time pressures felt by many finishing job shops. “Our average turnaround time is 3.1 days,” he says. “That’s down from 8.5 days five years ago.”

One of the elements that has enabled Hixson to keep up with customer demands for faster turnarounds is better use of personnel according to production manager Greg Gannon. “We’ve brought in some new people, we’ve adjusted our management style and we’ve empowered our department lead personnel based on their talents. By doing this we’ve been able to focus on efficiency.

Another weapon is Hixson’s home-grown job tracking system, which Gannon feels gives the company a competitive edge. “It’s a system like I’ve never seen in any other shop,” he says. “Our owner created it. In every department there’s a computer terminal, and workers can call up data on the customer, job number, priority, when it came in, when it’s supposed to ship, how many hours it’s been in the department, etc.

“If you go deeper into a job, you can find out about past performance, see a ‘report card’ of what we’ve done for the customer in the past, find out how many pieces we’re making per hour and who worked on the job, see how long it was in a particular area, learn how it’s supposed to be shipped--anything and everything you might need to know about a particular job,” Gannon says.

Hixson managers also use close relationships with some vendors to help them keep up with accelerated production schedules. A case in point is the company’s relationship with Shercon Inc., a supplier of custom masking products based in nearby Santa Fe Springs, CA. Shercon maintains Hixson’s mask inventory, replenishing as needed. Shercon personnel also work with Hixson managers to target repeat jobs with sufficient volume to possibly justify a custom masking solution.

Complex Masking Job

“Many of our parts require masking,” Gannon explains. “We have a separate department with two shifts running and 20 employees. We use various methods: tape, wax, custom masks.”

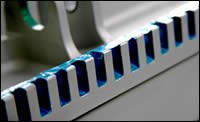

On a walk-through of the masking department—Hixson has 20 employees, working in two shifts, who only do masking--Shercon engineer Jimmy Rodriguez noticed workers using tape to mask slots on an aluminum alloy hinge. Destined to be part of an aircraft wing assembly, the part requires a multi-step process that includes multiple masking operations.

“The part is ‘cut up’ in various angles,” Gannon explains. “If you were to picture a fine-tooth comb, we’d be masking all those teeth individually.” It was a tedious and time-consuming process—120 minutes per part.

The components are first checked for defects using dye penetrant inspection, then masked and sulfuric acid anodized, according to Gannon. This is followed by masking and application of a dry lubricant to the hinge areas, then masking and application of a liquid organic primer.

“The dry lubricant is a spray application that’s used in part wear areas,” Gannon explains. “Then we apply the primer. There’s quite a bit of masking between the teeth and between operations.”

Even with the multi-step finishing required, masking accounted for the lion’s share of processing time and creating significant production bottlenecks. And, Gannon says, the company runs the parts pretty regularly—three or four lots per month, each with anywhere from 30 to 60 pieces.

Molded Solution

Rodriguez worked with Hixson personnel to design a custom molded plug that simply inserted into the teeth of the hinge without interfering with the coating process on the outside faces of the hinge.

After producing a prototype mask design that used multiple plugs to accommodate hinges with differing numbers of teeth, Shercon sent the design to Hixson and awaited feedback. The only request was for a slightly softer rubber.

“We fine-tuned the hardness so operators could more easily insert the plugs,” Gannon explains. “It was about a three-month project to get the thing the way we wanted it.”

Shercon substituted a softer material and put the mask into production. “Because the process used on this part required several coats and wash steps, we used our Ultrabake material,” explains Rodriguez. “It’s resistant to shrinkage and compression sets, so it was easy to accommodate Hixson’s request for a softer plug.” Used in powder coat, e-coat, plating and anodizing applications, the material can withstand processing temperatures to 600°F, according to Shercon.

Productivity Boost

The custom-molded masks dramatically reduced prep time for the aerospace hinges, eliminating a significant production bottleneck. “Masking prep time for each part went from two hours to less than 20 minutes,” Gannon says.

The plugs were also very durable, he adds. “We still have the original plugs,” he says. “We just clean the coating off with a little acetone, and they go right back in onto the line.”

Gannon sees Hixson’s relationships with Shercon and other vendors as one of the ongoing keys to the company’s success. “I can leverage their brainpower, and they’re constantly showing us new stuff,” he says. “They’re always improving the quality of their products, and that’s important to us given our customers’ quality demands.

“Shercon was a big help on this project, but it’s just one project. Think about that times 20,” he concludes.

RELATED CONTENT

-

Anodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

-

Painting a Boeing 737: See The Video

The cost is between $100,000 to $200,000 to prep and paint each plane, depending on which colors are chosen, and how many colors.

-

Evaluation of Hexavalent Chromium Free Bond Primers for Aerospace and Defense Applications

Three hex chrome free bond primers demonstrated that they can surpass the 960 hour threshold before exhibiting panel corrosion away from the scribe.