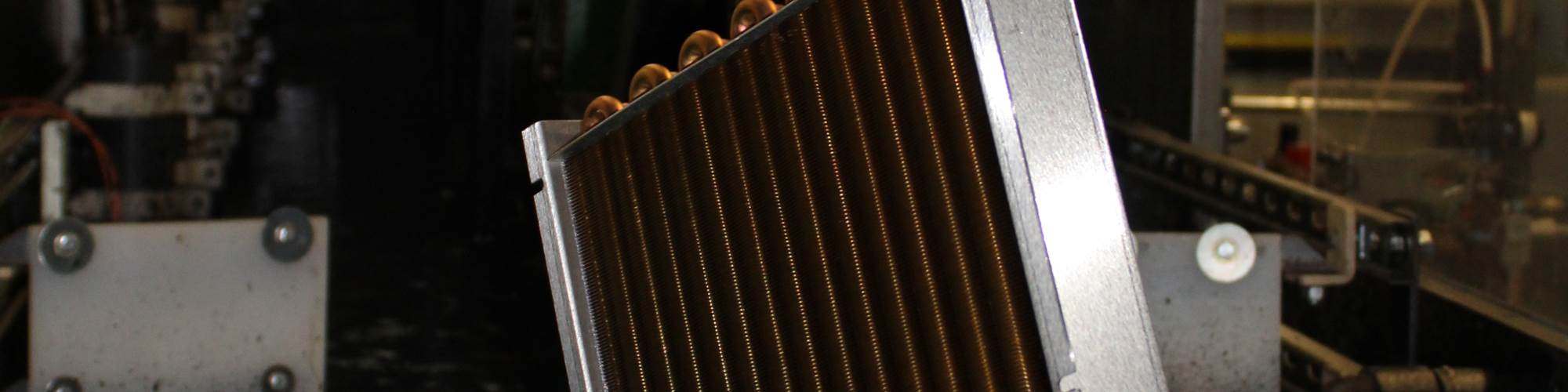

Giering Metal Finishing’s work on heat exchangers for chest X-ray systems has been an area of growth for the company during the COVID-19 pandemic. Credit: all photos Giering Metal Finishing

Giering Metal Finishing (Hamden, Conn.) is one of those family-owned shops that has been around for decades and coated parts through some pretty interesting times. What started out as a side job painting dental chairs in the late 1930s eventually became an electrostatic finishing shop for the armed forces during World War II. Giering Metal Finishing incorporated in 1954 and, as time marched on, the company expanded into a range of finishing services, from degreasing and pretreatment to plating and anodizing and liquid coatings. Since then, the company has zeroed in its focus on ecoating, powder coating, liquid paint, conversion coating, silk screening, masking and packaging. Today, the third-generation company’s president, George Giering Jr., finds himself steering the company through yet more interesting times during the COVID pandemic.

“We’ve been very fortunate,” Giering says. “We’ve stayed busy throughout this entire thing. It’s very interesting to see which sectors are staying busy and which are not.”

Featured Content

Overall business has been good for Giering Metal Finishing despite the pandemic, in part due to the company’s diverse customer base. Giering thinks smaller shops have the advantage of being nimble, making pivots from slower markets and putting additional focus in other areas more easily than some bigger operations might be able to.

Not surprisingly, one area that has remained steady for Giering Metal Finishing is medical. The company’s work in the medical sector amounts to roughly 15% of its business. Some of the projects the company has in the works include ventilator housings, centrifuge bases, parts for the DaVinci surgical system and X-ray machine components.

In the early days of COVID, it was all about ventilators. With an uptick in the beginning of the pandemic, Giering Metal Finishing’s ventilator business has remained consistent and is currently around 30% above normal levels. Working on ventilators isn’t a new business for the company — it was applying liquid coatings to housings for the machines well before COVID increased demand.

A cosmetic liquid coating is applied to ventilator housing panels.

“Ventilators and respirators have always been important — if you can’t get oxygen into the bloodstream, you’re in trouble. One of the ABCs of life-saving techniques is making sure oxygen is getting to the body,” he says.

Giering is speaking from experience. In addition to running the family company, he serves as a volunteer EMT. He’s been paying close attention to how the coronavirus situation has evolved.

“I think that a lot of the initial knowledge [about COVID-19] when we were first talking was that it was all pulmonary. As things have evolved, I think that people have realized it’s more vascular now,” he says. “At least for our business, the largest growth has been with a customer who manufactures chest X-ray systems.”

Electrocoating complex components

Heat exchangers for a chest x-ray system are put through a rigorous cleaning operation and the final finish is a black cathodic epoxy electrocoat.

Giering Metal Finishing’s work on heat exchangers for chest X-ray systems has doubled or tripled, depending on the month. According to Giering, the heat exchanger is a complex assembly made up of multiple metals including aluminum, copper, brass fittings and stainless steel. The parts are put through a rigorous cleaning operation and the final finish is a black cathodic epoxy electrocoat. The product’s assembly involves welding, slip fit parts and good deal of masking.

“Because it’s a heat exchanger, you have fluid going in and coming out,” explains Giering. “We have to make sure to protect the internal tubing by masking off the inlet and you cannot have any leakage.”

Giering says it took almost a year to dial in the process, adjusting temperatures, cleaner concentrations, etch time and rinse water quality. Agitation in the bath was important for penetration throughout the part.

“You want good chemical changeover on all surfaces — not only on the outside of the product, but also inside,” says Giering “When you’re ecoating, you want to make sure that you have good fluid motion throughout the entire part.”

Other coatings were tried for the heat exchanger, but conventional spray guns aren’t effective for uniform coating in hard-to-reach areas and plating doesn’t have the throw power that electrocoat does. “That’s why ecoating was such a great application for this product,” says Giering. “It deposited such a nice uniform finish on every single nook and cranny of the part that you would never be able to achieve with any other finish.”

The right finish for the application

A liquid coating works well for the casting quality of this centrifuge base.

Giering Metal Finishing’s work in the medical sector touches each of the areas they specialize in. The company is liquid coating centrifuge bases. The bases are large castings, and because the castings are so porous, painting the part was the best option because of the cure requirement.

“We tried powder coating, but we had so much outgassing that it just was not feasible,” says Giering. “So a nice liquid coating with a nice texture on the outside to kind of hide that casting quality worked perfectly.”

As for powder coating, the company processes a component for the DaVinci robotic surgical system for Intuitive Surgical Inc. (Sunnyvale, Calif.). “It’s a highly cosmetic powder. We put it through a sieve but the cosmetics are qualified using a magnifier. So we’re taking a really zoomed-in look at the finish.”

Work for the medical industry is only one part of what has enabled Giering Metal Finishing to navigate challenging times. Giering attributes the company’s success to its ability to quickly adapt and take on a diverse range of projects.

“I think that this is probably kind of a hard thing to quantify,” he says. “But the smaller the business, the busier they’ve been. I think when you’re small, you’re able to make key business decisions much easier and change your direction.”

RELATED CONTENT

-

Applications Innovation Leads to Better Masking Solutions

When masking product failures are costing you money, it pays to work with an expert that can select or engineer the most efficient solution.

-

Painting a Boeing 737: See The Video

The cost is between $100,000 to $200,000 to prep and paint each plane, depending on which colors are chosen, and how many colors.

-

Are TGIC-Free Powder Coatings Right For You?

This alternative to TGIC-based polyester powder coatings offers similar performance and enhanced transfer efficiencies.