Greaseless to Greatness for Structured Surface Finishes

The conversion from greaseless abrasive compounds and buffs to nonwoven technology for textured satin finishes without the mess.

For many years, skilled finishers around the world found a way to take simple cloth buffs, bundle them together and apply a greaseless abrasive compound to make beautiful, textured satin finishes on home furnishings and other products.

However, it is difficult to maintain the consistency of the finish, keep the output high and constant and train personnel to deal with the difficult environment created by the greaseless compound. With the need for an additional greaseless compound to be added to the buff to ensure the textured finish is maintained, inconsistency within the process is a significant concern. Oftentimes, the greaseless compound ends up not just on the buff, but on the walls, floors and even the finishers, whose uniforms and aprons often show the most wear. Additionally, eye safety is a concern when working with airborne compounds. Skilled finishers are known to have left the industry because they could not continue to deal with the mess and safety concerns inherent with the greaseless procedure.

Featured Content

Today, nonwoven manufacturing technologies are available to offer finishers a beautiful, textured satin finish without the mess and safety hazards that greaseless compounds produce.

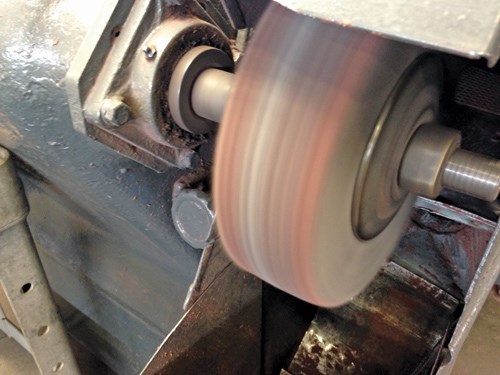

A nonwoven, very fine finishing flap wheel used on a robot installation.

Nonwoven Nylon

New surface finishing products, made of a nonwoven nylon web impregnated with abrasive grain and resin, have been found to save time and money, and are safer for operators

to use.

There has been some reluctance on the part of finishers and company leadership to migrate from the old greaseless compound technology. Some of this reluctance is based on the need not only to find a way to match the current finish, but also to ensure value in the nonwoven technology versus the cost of the old method. Total cost analysis has motivated some to make the switch.

In addition to this nonwoven technology, a no-smear resin technology is also available. This technology offers exceptionally smooth, smear-free finishes, eliminating rework process steps and improving productivity by delivering between 25 and 50 percent savings compared with the greaseless compound process. These savings are generated by a combination of significantly shorter cycle times per workpiece, due, in part, to the elimination of the application time of the greaseless compound, and a more effective abrasives design to make consistent and higher structured satin finish. Another important advantage of the nonwoven technology is the ability to automate nearly any current process that uses the greaseless/buff method.

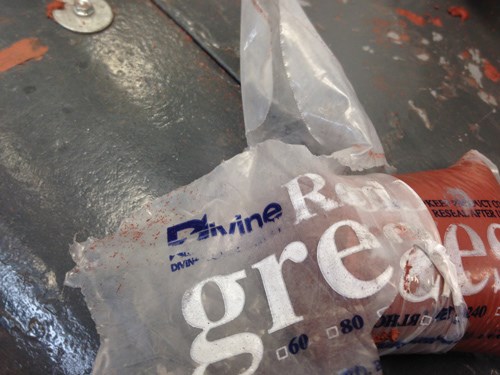

Greaseless compound is applied to center sewn buffs for structured satin finish. This requires constant reapplication of the greaseless compound and is nearly impossible to keep consistent from part to part.

Straight and Structured Finish

Certain varieties of nonwovens fit different parts and finish requirements, depending on what is being produced. For flat parts, a nonwoven belt has been developed that can be used for a straight and structured finish. For areas that have a tight radius, wheels of different densities are effective, while nonwoven flap wheels or interleaf wheels are a better approach for smooth-structured finishes. The interleaf wheel is a combination of nonwoven material and coated abrasives in a nearly endless configuration. The ability to customize nonwoven material with various coated abrasive grains and grit sizes means nearly any current finish can be matched with the nonwoven method.

This customization makes automation possible. No matter the expected final finish, the interleaf technology and capability can create a finish that enables a robotic/automated operation to function better than the traditional manual process with full repeatability and consistency, which has not been possible with the greaseless compound and buff method.

With the improvements made by robot integrators, such as Acme Manufacturing, Applied Controls Technology and Pinnacle Technologies, the ability to “read” the size of the wheel as it wears enables wheel speed and pressure adjustments. These capabilities enable the end user to create an exact finish for each and every part.

Due to the constant need for additional greaseless compound, cost savings add up when converting to nonwoven technology. The need to keep the greaseless compound cool at all times is an additional cost, as well as a logistical issue. And once the application time is factored in, a total cost savings of more than 50 percent can be realized.

Greaseless compound bar that would have to be applied to a center sewn buff repeatedly in order to give a structured finish.

An example of this savings is a manufacturer that was working with die cast aluminum using a buff and greaseless compound as a method for putting a textured satin finish on the surface of its die-cast aluminum parts. This process was slow due to constantly adding the greaseless compound to each part, then allowing it to dry before moving to the next step. In addition, it was inconsistent because there was grit coming off the buff during the process, making one side of the part coarser than the other. And it was messy because the greaseless compound would get on everything when applied to a spinning buff.

When the company began using one of the nonwoven technology products, it was able to achieve a consistent textured satin finish. The grit was impregnated onto the nonwoven surface and no longer had to be reapplied to the part. This kept the finish consistent through the life of the wheel, and the operation was faster and cleaner without the need for reapplication. With the nonwoven technology method, cycle time improved by 50 percent with a yearly savings of $185,000.

Mike Shappell is a senior application engineer for coated abrasives. For more information, please visit nortonabrasives.com.

Norton

Originally published in the May 2016 issue.

RELATED CONTENT

-

Polishing vs. Buffing: What's the Difference?

Is polishing the same as buffing? Mechanical finishing expert, Pat Wenino, explains the differences between the two processes.

-

Achieving a Mirror Finish

New buffing technology minimizes clean-up and improves quality, cycle time and finish on automatic/robotic applications.

-

Glass Bead Blasting as Plating Pretreatment

What are the best practices for using blasting in preparation for plating? Angelo Magrone of Bales Metal Surface Solutions discusses the ins and outs of glass bead blasting.