In Pursuit of Precision Blasting

A look at the state of abrasive blasting technology

Blast cabinets are a familiar sight in many finishing shops, but “precise” isn’t a word many finishers would pick to describe how they’re used. However, blasting is an essential process in making many precision components, from aircraft engine parts to metal cutting tools, medical instruments and orthopedic implants.

The more critical the surface finish requirements, the greater the need to tame the blasting process, control the sources of variation and take measures to ensure consistent quality results. To identify blast system features that increase the precision of the technology, it’s helpful to look at the types of blasting equipment and blast media that are in general use and focus attention on aspects that impact process control.

Featured Content

The reason blast machines are found in so many finishing shops is the wide variety of tasks they can handle using different blast media. Blast cleaning is a fast and effective way to remove dry surface deposits from metal components. Even tough scale, oxidation and rust can be pulverized and taken off by more aggressive shot or grit blasting. Bead blasting can blend in superficial scratches and minor surface imperfections, and it’s also used to produce an attractive, semi-reflective finish.

Grit blasting is a common technique for removal of organic coatings. It’s an essential method of increasing surface area and generating specific surface texture or roughness for promotion of adhesion and bonding of coatings. Blast treatment is a recommended or required step in numerous OEM process specifications. This list of blasting applications clearly demonstrates its versatility in practice.

Suction-Feed Delivery

In simple terms, precision in blasting depends on control of blast media and media delivery. A brief review of the fundamentals of cabinet-blast media delivery will highlight some of the most important ways to improve control and consistency.

The most common blast cabinets are of the suction-feed type, in which blast media particles are drawn into the blast gun by an induced vacuum and accelerated within the gun by a metered stream of compressed air. Suction guns have two hoses, one to supply compressed air at regulated pressure and another, a vacuum hose, to feed abrasive to the gun. Particle velocity, vacuum and media flow all increase as air pressure is increased. The volume of air used by a suction gun operated at the desired blast pressure is determined by the bore size of the metering air jet.

In most suction-blast equipment, the loading of media particles in the air stream and the volume of media flowing to the gun are adjusted using a vented pick-up tube that allows varying amounts of air to be mixed with the abrasive until maximum media flow is achieved with no overloading or surging. If this adjustment cannot be positively indexed and locked-in, reliable control of media flow is compromised and a significant source of variation in performance is introduced into the blasting process.

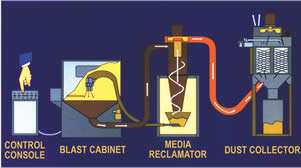

The simplest cabinet blasting machines consist of a vented enclosure with a sloped hopper at the bottom where the media pick-up tube is located. A blower-powered dust collector maintains negative pressure in the cabinet, extracting airborne dust. After impacting the work, media particles fall back into the feed hopper by gravity. In this most basic of blast cabinets, the entire contents of the media hopper are emptied out and replaced with new media when the media mix exhibits an excessive percentage of fractured particles and contaminants.

Obviously, there are problems with such a “no frills” blast system when viewed from the perspective of process control and consistent finish. Dust can reduce visibility in manual blast cabinets, making it difficult for operators to see the work. Because only light dust particles are extracted, the media mixture becomes increasingly laden with undersized particles and material that has been removed from the work. With every few minutes of use, composition of the media mix essentially changes, leading to noticeable differences in appearance between identical components blasted at different times throughout the day.

The only way to get some semblance of consistency from such primitive blast cabinets is frequent media change-out. To maintain repeatable results, it might be necessary to empty and refill the media hopper more than once per hour.

Suction-Feed Media Delivery

Pros: Simplest design, low up-front costs

Cons: Frequent media changes, limited repeatability

Pressure-Blast Delivery

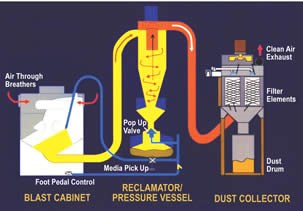

Direct pressure-blast systems enable faster coverage of large components and more energy-efficient media delivery. In pressure-blast equipment, the media is held in a pressurized vessel and metered into a flow of compressed air in a single, heavy-gauge hose where the blast particles are accelerated throughout its length.

The grit or metering valve at the head end of the pressure-blast hose enables adjustment of the volume of media loaded into the air stream. As with the suction-blast pick-up tube, the design and positive adjustability of the grit valve is a key feature for maintaining the consistency of the pressure-blast process.

At a given pressure level, particle velocity exiting the nozzle is higher with direct pressure than with suction-blast media delivery because media is accelerated through the entire length of the blast hose, not just in the body of the blast gun and the nozzle. The higher-energy particles can accomplish more work in a shorter time. A large-bore pressure nozzle also creates a bigger blast pattern and can be positioned at a greater distance from the target surface, allowing the spray of media to fan out and cover a larger area.

Pressure-blast systems typically work about four times faster than suction-blast. They also make more efficient use of costly compressed air because all of the air is used to accelerate blast media. In a suction gun, some air is used to generate the vacuum for media pick-up.

But these advantages come at a price. In addition to higher purchase cost, the more complex equipment will require somewhat higher maintenance expenses for both the blasting apparatus and the parts of the cabinet-blast system exposed to the powerful blast.

Pressure-Blast Delivery

Pros: Higher-energy particles, larger blast pattern

Cons: Higher initial cost, maintenance expenses

Media Reclamation

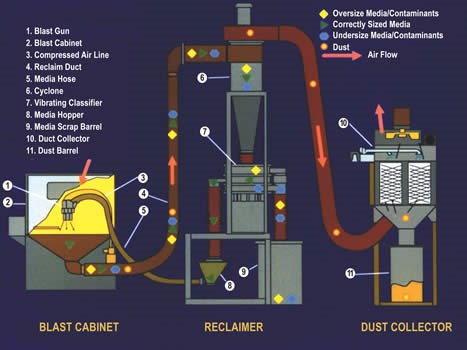

Regardless of delivery system, more efficient cabinet-blast systems include a cyclone separator or cyclonic media reclaimer positioned between the blast chamber and the dust collector. Equipped with a blower or using the air flow created by the dust collector blower, the cyclone draws a strong flow of air from the blast cabinet, carrying media, fractured particles and dust out of the chamber through a duct hose or pipe.

Inside the body of the cyclone, media and dust are separated by mass. The heavier particles stay to the outside, traveling in a spiraling motion down the cone of the cyclone to a media hopper, while the lighter dust is suspended in the extraction zone at the center, from which it’s ducted to the dust collector. Separation efficiency can be tuned by adjusting the air flow into and out of the cyclone by means of a blast gate or butterfly valve at the inlet of the dust collector and by adjustable vents on the cyclone itself.

Fine adjustment of air flow through the cyclone is required for effective separation of lighter fractured media particles. Too little air flow will result in a slower, dustier operation; too much will carry good media particles off to the dust collector. Inspection of dust collector waste provides evidence of the cyclone’s performance. In a properly adjusted system, 5–10% by weight of the material in the dust bin should be “good” media particles. If the contents are purely dust, it’s certain that fractured, ineffective particles are abundantly present in the blasting mixture.

Cyclone media reclamation offers numerous advantages. It eliminates batch media changing—new media must be added to the system only in small amounts to compensate for attrition. Cabinets equipped with a cyclone are less dusty in operation, and visibility within the blast enclosure is improved. Tunable separation offers some degree of control over blast particle size, enabling more consistent results and uniform finish.

It is important to note that the size and proportions of the cyclone, as well as duct diameters and the extraction value of the dust collector, must be engineered to match the number and type of blast guns in the cabinet. Also, equipment designs that don’t enable accurate and positive adjustment of the cyclone and dust collector air flows will be less reliable in performance.

Advanced Reclamation

Some applications need to allow for more precise control over the blast particle mix. Deburring and deflashing operations, for example, generate significant quantities of media-contaminating debris. Another situation that requires precision control of media is processing of parts that require a specific surface roughness.

In these cases, cyclone reclamation alone cannot be expected to perform satisfactorily, especially in an automated system that must keep pace with production. A vibrating-screen classifier in the cyclone reclaim stack-up to continuously sieve 100% of the material extracted from the blast chamber before the media recirculates can dramatically improve system performance.

Besides separating foreign matter removed from the work, media classification provides the highest degree of control over the size of the blast particles themselves. High media uniformity optimizes blasting effectiveness and keeps process control within tight limits.

A typical vibrating-screen classifier consists of three screens. The top screen captures material larger than the specified media size and removes it to a scrap bin. The middle screen retains media particles that are the correct size and returns them to the blast machine. The lower screen collects under-size media and fine debris, which is normally considered scrap.

Automated Blasting

Even with the most advanced manual blast equipment, practiced technique and constant operator attention are required to avoid uneven coverage and over-blasting of sensitive features. The quality of the results can vary widely between users and from part to part. Besides the labor cost and inconsistency of manual processing, you may also be concerned about worker injury due to repetitive motion in hand blasting operations.

Automated blasting equipment operates on the same basic principles described above, but eliminates many opportunities for human error, reduces processing time and makes possible a repeatable finishing process. Automation of blasting is practical for components that are processed in volume or for high-value work where stricter quality standards apply.

From the many types of automatic blast machines available, including tumble-blast, through-feed conveyor, rotary table and spindle-blast systems, an experienced equipment manufacturer can recommend an automated system that matches your production and finish requirements.

When an application requires the highest degree of precision for a critical surface preparation requirement, a robotic blasting machine is a reliable and flexible alternative. In addition to machine-tending robots for part loading/unloading, there are two ways a robot and blast system can be integrated.

In the first, the robot not only loads and unloads components but also reaches into the blasting chamber and presents them to the blast from one or more fixed nozzles. The robot can be programmed to constantly maintain the correct angle, distance and surface speed relative to the blast, allowing flawless coverage of target surfaces. Needless to say, this mode of component handling requires that the materials and design of the robot’s end effector or gripper withstand direct exposure to the potentially harsh blasting abrasive.

In the other type of integration, the robot is mated to the blast cabinet as a nozzle manipulator. A custom-tailored skirt seals one wall of the blast cabinet and fits tightly around the end of the articulated arm to protect the robot from dust and blast media.

While programmed robotic motion often mimics the technique of the most skilled human operators, robots can produce some movements people can’t make. The robot also can tirelessly duplicate exactly the same blasting routine. In many cases, motion of the blast machine, such as table rotation, is servomotor-driven and synchronized by the robot controller as an additional axis of motion. Once a program has been developed for a particular component, it can be recalled and repeated at any time.

In robotic blasting installations, it’s vital that the blast machine be capable of the same level of accuracy as the robot itself, and that the controls of the blast system be fully compatible with those of the robot. With the increasing use of robotics in painting, thermal spray coating and other finishing operations, we can expect to see more robot blasting machines in the future.

Automated Blasting

Pros: Shorter cycle times, highest repeatability

Cons: High initial cost, requires accuracy and control compatibility

RELATED CONTENT

-

Preparation of Stainless Steel for Powder Coating

Should type 316 stainless steel castings be sandblasted before powder coating, or can they be chemically etched? Should the parts be pre-heated in an oven before coating?

-

Calculating Oven Heat Load Capacity

Please explain how to calculate the heat load capacity of a paint baking oven, using aluminum alloy wheels as an example.

-

Understanding Infrared Curing

Infrared cure is gaining increased attention from coaters as a result of shorter cure cycles and the possibility of smaller floor space requirements when compared to convection oven curing.