Published

Just Peachy in South Carolina as Palmetto Plating thrives on ingenuity, automotives

More than 1 million of them pass through tanks each year at Palmetto, which specializes in anodizing, black oxide, chromate conversion coatings, decorative and hard chrome, electroless nickel, pickling, and passivation.

#pollutioncontrol #masking

Contributor

The first time John Cutchin tried his hand in the plating business, he was still in high school and a little wet behind the ears when it came to the science and chemistry of surface finishing.

“I plated a pair of baby shoes for someone,” Cutchin says. “It was just something I wanted to try, and it was interesting.”

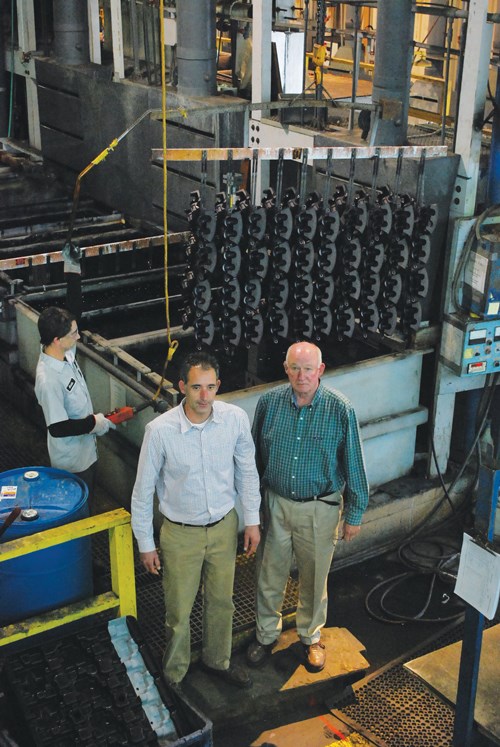

Several decades later and now the owner of Palmetto Plating in Easley, S.C., Cutchin is still plating shoes, albeit the casings for brake shoe pads for the stylish Chrysler 200 and 300 vehicles.

More than 1 million of them pass through tanks each year at Palmetto, which specializes in anodizing, black oxide, chromate conversion coatings, decorative and hard chrome, electroless nickel, pickling, and passivation.

Cutchin and his staff—which includes his heir apparent, son Hunter, who serves as vice president of purchasing and customer service—run three shifts at their plant, plating protective coatings on a variety of parts. But the auto industry in particular has been very good to Palmetto and other platers in the Atlantic Coast and Southeast region.

A BMW plant opened in nearby Spartanburg, S.C., in 1994 and plans to expand again by 2014 and hire 1,200 more workers. A $1-billion Volkswagen plant opened in Chattanooga, Tenn., in 2011 with the hope of selling 1 million cars in the U.S. by 2018 and helping to create nearly 10,000 supplier jobs in the region.

The U.S. Department of Commerce says that, based on the 2011 value of exports from its Spartanburg facility, BMW is the largest automotive exporter from the U.S., producing more than 1,000 vehicles each day and exporting about 70 percent of them to 130 countries.

“We call this stretch of I-85 the Autobahn,” Cutchin says of the highway running alongside the BMW plant. “The automotive industry has really been a good thing for all of us.”

But car parts are not what made a name for Cutchin and his Palmetto Plating plant in the industry. In fact, Palmetto is known throughout the eastern seaboard of the U.S. as a resource for plating, passivating or electropolishing very large piece of equipment and components. Vessels, tanks, heat exchangers, pipes and other components seem to find their way to Palmetto’s Easley plant or to its sister company just up the road that specializes in black oxide finishes. Being centrally located to cities such as Atlanta, Charleston, Columbia and Charlotte has been a big plus.

“That, and I just can’t say no to anybody,” laughs Cutchin, who started his company in 1964 fresh out of college at Clemson University.

For example, the Patterson Pump company in Georgia called Cutchin about passivating several pipes for a water project it was working on. The pipe sizes were huge—between 48 and 66 inches in diameter. Several larger platers had passed on the project, but Palmetto was able to use a little ingenuity to get the parts plated and back to Patterson Pump.

A stair-making company called Palmetto about electropolishing a unique staircase that was 4-ft wide and 24-ft long. At roughly two tons and made up of several hundred parts, the job scared off more than a few job shops, but Cutchin embraced the task.

“One thing that I have learned during my time in business is that things are always changing,” he says. “Customers change, processes change, even employees change, but you have to move forward and continue to meet your customers’ expectations.”

A big benefit for Palmetto is its partnership with suppliers who weigh in with technical advice and expertise on tricky projects, or on new specifications being asked of Palmetto.

Over the past year, Palmetto and Metal Chem, Inc. of Greer, S.C., have been working closely to design a cycle to blacken medium-phosphorous, electroless nickel plating for several existing and potential customers. Hunter Cutchin and Metal Chem’s Jordan Beavers have tested and optimized a process to blacken electroless-nickel-plated copper for heat shield parts for one of Palmetto’s customers.

“Their objectives were clear, which were to achieve a non-smutty, uniform black coating that maintained its color despite some wear,” says Marc Aleksinas of Metal Chem. The company’s Meta-Black EN was developed as a room-temperature post dip designed to blacken mid-phos Metal Chem electroless nickel.

Aleksinas says Meta-Black EN creates a thin black nickel oxide film that is free of loose smut and maintains integrity for more than 50 hrs neutral salt spray exposure (ASTM B117). A typical process cycle includes:

- Electroless nickel plating using Meta-Plate Ultima MP EN, 0.5-1.0 mil

- 2x clean rinse (DI preferred)

- Meta-Black EN, 75°F for 45-150 sec

- 2x clean rinse (DI preferred)

- Dry

“Adding a baking step can improve hardness and wear resistance of the Meta-Black EN,” Beavers says. “Also, clear topcoats can provide better corrosion protection and wear resistance as needed.”

Beavers and Hunter Cutchin discovered during testing that the black coating can be affected by substrate metal and surface conditions. “However, length of immersion time in Meta-Black EN along with a clean, active deposit prior to blackening can aid in developing a consistent, black deposit,” Beavers says.

The entire heat-shield-parts project was a testament to John Cutchin’s years of experience and know-how.

The customer used the heat shield to cool down fiberglass strands as they emerged from a formulation process. When the customer mentioned to Cutchin that the heat shields worked best after a few hours and days of use, when they would turn black from the heat source, Cutchin recommended the blacken electroless nickel process to get the desired result from the beginning.

Walking around the Palmetto Plating shop and strolling through its parts staging area reveals the story of how the company got to where it is today and where it is headed when Hunter takes over for his father, John. Large, irregularly bent pipes from the first nuclear energy plant to be built in the U.S. in 30 years await coatings on Palmetto’s loading dock. Large, oversized vessels are getting a coating in the Palmetto “Rubber Room,” an outdoor plating facility layered with rubber walls that Cutchin built several years ago to handle projects with odd sizes and shapes.

“A lot of what we do is thinking outside the box,” Cutchin says. “To that end, we are constantly looking for new ways to better serve our customers by improving efficiency and investing in new technology.”

For more information on Palmetto Plating, please call 864-859-9314 or visit Palmettoplating.com. For information on Metal Chem, please call 864-877-6175 or visit Metalchem-inc.com.

RELATED CONTENT

-

Nickel Electroplating

Applications, plating solutions, brighteners, good operating practices and troubleshooting.

-

Aluminum Anodizing

Types of anodizing, processes, equipment selection and tank construction.

-

Choosing and Troubleshooting Copper Electroplating Processes

Learn more on this inexpensive and highly efficient process.