Liquid Clinic: Flushing a Fluid Line, Cutting Costs

Justin Hooper from Carlisle Fluid Technologies talks cutting costs for flushing a fluid line using a solvent flush.

Featured Content

Q. How can we lower our costs when changing colors or flushing a fluid line?

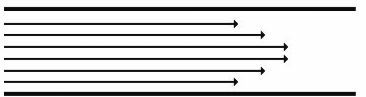

A. One of the major uses for solvent in a spray finishing system is flushing out a paint line when changing colors or cleaning the system. This is typically done with a straight solvent flush. Solvent flowing through a hose will travel in what is termed a “laminar flow” (see Figure 1). Since the path of least resistance is down the middle, it takes a lot of solvent to clean the inside perimeter of the hose.

Figure 1 – Laminar Flow

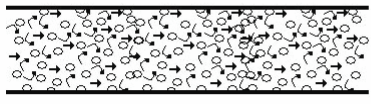

By injecting air into the solvent supply, the laminar flow changes to a turbulent flow (see Figure 2). This turbulent flow gives us the following benefits:

- Solvent savings (typically around 75 percent)

- Time savings (typically around 38 percent)

- Lower solvent costs

- Lower disposal costs

- Cleaner equipment

- Fewer color-matching problems

Figure 2 – Turbulent Flow

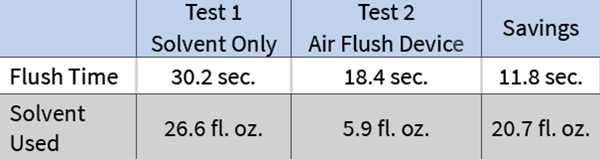

Air Solvent Mix Device Test - 25' ¼" ID Hose

An example of annual savings would be:

- 20.7 fl. oz. × 8 color changes/flushes per day × 240 days/year = 39,744 total fl. oz. saved per year

- 39,744 total fl. oz. ÷ 128 oz. per gal = 310 gal. per year

- 310 gals × $9 per gal = $2,790 solvent savings

- Multiply above times total qty. of guns

- 310 gals. × 8 lbs. VOC per gal = 2,480 lbs. saved per year

This does not include permits, disposal costs, filters, etc. To better understand how much money could potentially be saved in your facility, investigate how long it takes to fill one drum of waste. Spend the time to better understand what is filling up that drum of waste, and work to reduce the solvent and paint going into those waste drums.

What if you just have a pressure tank, hose, and a gun? The cost of many modern coatings are in the area of $100 per gallon or more. If one can recover the coating from the fluid hose before flushing the hose with solvent, the amount of money saved can be considerable over a period of time. A 25-foot length of 5/16" fluid hose contains approximately 12.7 fluid ounces. Flushing the hose 10 times would waste (or save) about 1 gallon of coating. Safety warning: do not use the following method to flush out high-pressure equipment. This method is designed to back flush operations using pressure pots.

Typical recommendations for back flushing a pressure pot are to hold a rag tightly over the air cap with the fluid pressure off and the air pressure on.

Note that the tank pressure has been relieved and the tank is open to atmosphere either by opening the tank vent or leaving the tank lid ajar. Holding a rag against the air cap with air cap in “operating” position results in no fluid being back flushed. The rag not only blocks the center annular hole of the air cap; it blocks the fluid tip opening preventing the air from entering the fluid tip.

Loosen the air cap retaining ring approximately two turns before applying the air pressure. This position raises the air cap above the fluid tip allowing the air to flow into the fluid tip, pushing the coating back to the pressure pot.

Back flushing your fluid lines results in lower coating costs, lower solvent costs and lower disposal costs.

For more tips on how to reduce waste for your facility, have a conversation with any equipment representative in the industry. You are paying for paint and solvent every day. Work with experts on how you can reduce these large costs and save your company money.

Justin Hooper is the strategic IoT manager and product manager at Carlisle Fluid Technologies. Visit Carlisleft.com.

Originally published in the October 2016 issue.

RELATED CONTENT

-

Drivers of Change

Is your metal finishing software ready for an upgrade?

-

Preventing Solvent Pop

Preventing solvent pop on an industrial paint line...

-

Is Your Electroplating Waste Hazardous?

Some that bears precious metals is, and there are a host of regulations to consider when recycling.