Low-Vapor-Pressure Solvents Can Reduce VOC Emissions

Smog Alert!

#vacuum-vapor

Smog Alert! Ozone Action Day!

Until recently, most of us probably associated these terms with California, but their use has become more widespread as federal and state environmental regulators have become increasingly concerned with air quality.

Featured Content

This increased concern has led to a growing list of restrictions on air emissions. States are limiting the emission of Volatile Organic Compounds (VOCs) in their efforts to reduce smog and improve overall air quality. And, as more states enact tougher, wider-reaching regulations, companies selling cleaning products containing VOCs are forced to innovate to meet the new restrictions without compromising performance. One alternative that has shown promise is the utilization of low-vapor-pressure (LVP) solvents.

Regulations, Regulations

The 1990 Amendments to the U.S. Clean Air Act identified consumer and commercial products as sources of Volatile Organic Compound (VOC) emissions. In 1998, the U.S. EPA established the National Volatile Organic Compound Emissions Standards for Consumer Products. These standards also apply to industrial general-purpose cleaning and degreasing products.

Since 1998, several states have established expanded, and more exacting, standards regarding VOC emissions. Many of these state standards took effect on January 1, 2005. The trend toward more stringent state standards will no doubt continue.

Volatile Organic Compounds

VOCs are very effective at dissolving and removing oily, greasy soils, which is why they have traditionally been used in many cleaning solutions. Two of the most widely used VOCs in aqueous cleaning products are 2-butoxyethanol (Butyl Cellosolve) and d-Limonene. The cleaning performance of these substances is well-documented and beyond dispute; but, as already noted, products containing these solvents are facing more regulation and restriction by federal and state environmental agencies.

With each new regulation, companies are pressured to switch to environmentally friendly “green” cleaners, and this trend is influencing new cleaning product formulations. A large effort is now underway at many suppliers of cleaning chemicals to develop “no-VOC” technology to replace these conventional solvents without compromising degreasing performance.

Identifying Potential Alternatives

Our first step in this effort was to define the term VOC, to give us some criteria for screening potential raw materials. 40 CFR chapter 1, part 59, 59.203, part F defines VOCs, and outlines which compounds are and are not considered volatile. The pertinent part of the definition specifies that a compound is non-volatile if its vapor pressure is below 0.1 mm Hg at 20°C. The challenge, therefore, was to identify low-vapor-pressure (LVP) solvents that fit this definition and still provide the required degreasing power.

Testing Potential Alternatives

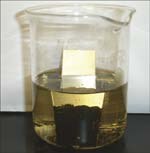

Technicians identified solvents fitting this definition, and began performance testing to characterize each solvent’s degreasing ability. The method consisted of soiling stainless steel panels with gear grease and weighing them on an analytical balance. The amount of grease and surface area exposed to the solvent on each panel was maintained as consistently as experimentally possible.

After being soiled and weighed, the panels were immersed in the test solvent for five minutes with no agitation, then removed and allowed to air-dry overnight. Once dry, the panels were reweighed and the percentage of grease removed calculated. Results were then compared with those obtained using Butyl Cellosolve and d-Limonene.

The candidate solvents outperformed Butyl Cellosolve but were unable to match the performance (90+% removal of grease) of d-Limonene. Because none of the solvents alone matched the performance of d-Limonene, the next step was to test some solvent blends. Two-component solvent blends were tested, but did not perform any better than the straight solvents.

As a final effort, some three-solvent blends were tested, and yielded a significant improvement in degreasing performance. The results were so surprising that tests were repeated multiple times for confirmation. The three-solvent blend represented on the graph removed almost 95% of the grease, performing better than d-Limonene.

Formulating a Final Product

Once we identified the synergistic degreasing performance of the patent-pending blend of LVP solvents, work began to incorporate the LVP solvent blend into a general-purpose cleaner. This task also entailed overcoming some daunting obstacles. For example, we found that one of the solvents degraded in water over time, and once degraded, its degreasing performance suffered significantly. Therefore a water-based product would have a significantly shortened shelf life.

On the other hand, LVP solvents are not water-soluble, so they could not simply be added to water at the point of use without emulsifiers. These factors required us to formulate a highly concentrated product that is almost 100% active with emulsifiers, thus enabling dilution with water at the point of use and ensuring an acceptable shelf life.

Solutions to these technical obstacles led to one additional obstacle: the high price per gallon of a concentrate compared to typical water-based general-purpose cleaning products. As always, success in overcoming this obstacle depends on the ability of sales personnel to explain, and prospective customers to understand, the need to consider the ultimate “use-cost” of a product versus the up-front cost per gallon.

In this case, the difference in the amount of product used offsets the difference in price. For example, the projected use concentration for the new LVP product is a 1% dilution, compared with the 5-10% use concentration typical of an industrial general-purpose cleaner. The bottom line is the LVP product, while priced more per gallon than a traditional general-purpose cleaner, provides superior cleaning, no VOCs, and ultimately costs about the same. Many industrial customers in the market for a general-purpose cleaner should find this compelling.

Conclusion

Chances are, VOC limits will continue to be lowered until they are zero. Given that assumption, instead of taking existing products and reducing their VOC levels to current allowances, our company took a zero-VOC approach to formulate new products utilizing LVP technology. As a result, we are now ahead of existing VOC regulations.

That being said, if a product doesn’t work, customers will not buy or use it, even if it does meet U.S. EPA and state VOC regulations. It has now been established that LVP solvents work. They are a viable alternative to traditional solvents, and, in fact, can outperform them in degreasing. The LVP solvent-blend product innovation path has been arduous, but has yielded some significant improvements. The no-VOC blend identified in this discussion allows a customer to use effective degreasing products without emitting VOCs to the air, thereby meeting and exceeding the new environmental regulations.

DuBois Chemicals, Surface Finishing

RELATED CONTENT

-

Plastics and Plating on Plastics [1944]

This republished 1944 AES convention paper presents an historic perspective of the early days of plastics in surface finishing - using them and plating on them, in the waning years of World War II. The discussion reviews the uses of plastics in plating equipment and processing at that time, as well as the coating of the plastics themselves, with accompanying application photos. You will note that today’s conventional plating-on-plastics processes lay far in the future. Surprisingly, CVD processes are discussed.

-

Reproducible Decorative PVD Coatings

Anytime and anywhere, PVD coatings on brass, zinc, stainless steel and ABS plastic can be reproduced...

-

Progress in Replacing Decorative Electroplating Chrome Coatings on Plastics with Physical Vapor Deposition Coatings

Decorative electroplated chrome coatings on plastics have been produced for decades. For environmental reasons, there has been a shift away from hexavalent chrome (Cr6) to trivalent chrome (Cr3) with increased investments towards elemental chrome PVD coatings to maintain the true chrome appearance.