Mechanical Finishing Q&A: Blasting Steel Parts to Clean and Profile for Coating Adhesion Specifications

How do we achieve these coating adhesion specifications and automate our process?

Q. We are a machining manufacturer and have an upcoming hot rolled welded steel pipe part. The print calls out an SSPC-SP5, 3 Mill profile, with adhesion testing, but we are not familiar with these specifications. How do we achieve these specifications and automate the process?

A. The Society for Protective Coatings (SSPC) and mill profile specifications are standard for surface preparation for paint and coating adhesion. Many coating manufacturers have the specification recommendations in the preparation instructions for each product. Wheel or air blasting the surface with various blast media will clean and profile to achieve both specifications. One blast process will accomplish both at the same time.

Featured Content

Blast equipment automation recommendations are hard to make without seeing the part or knowing the production rates. Media selection would also help determine what systems to recommend. Wheel or air automated blast systems could include J-belt or basket tumble blast, in-line conveyors, rotary tables or spinner hangers.

Wheel blasting

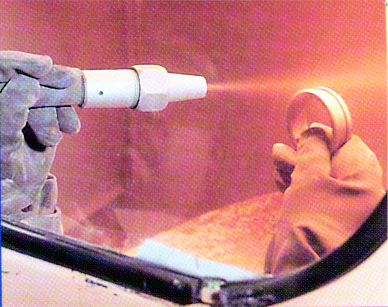

Air blasting

Common industrial recoverable blast media that achieve the specifications are: wheel blast medias; air blast medias; ceramic grit or shot; aluminum oxides; steel or stainless grit; silicon carbide; steel or stainless cast or cut wire shot; ceramic grit or shot; steel or stainless grit; or steel or stainless cast or cut wire shot.

Cleaning (SSPC specifications) is the removal of contaminants. Blasting with angular-shaped abrasives, rather than round particles, chip away and remove contaminants on the peaks and valleys of the surface profile, quickly creating a contaminant-free surface.

Profiling (mill profile), on the other hand, is the term used for surface roughness. The depth of surface profile is specified in micrometers (mills). The mill range for most pre-coat adhesion applications is between 1–4 mills. Larger blast media create higher profiles and increase surface area, resulting in higher adhesion or anchor pattern capabilities.

Specifications

Cleaning. SSPC is a non-profit association concerned with surface preparation, coating selection and coating applications. The National Association of Corrosion Engineers is a credited standards developer for practices and methods of surface preparation when corrosion is a factor.

The SSPC-SP5 and NACE 1 specification is a white metal blast. It is the complete removal of all visible oil, grease, dirt, dust, mill scale, rust, paint, oxides, corrosion and other foreign matter that must be blasted.

Other specifications are SSPC-10 or NACE 2 near white metal blast; SSPC-SP6 or NACE 3 commercial blast; and SSPC-7 or NACE 4 brush-off blast. The ISO8501-1 and SSP-Vis 1-89 specification shows visual samples of the SSPC finishes. The visual samples are not intended to replace the specification, but, instead, to visually assist.

Mill Profile. ASTM D2651-0 (2008) is the standard guide for mechanically preparing surfaces for adhesion bonding. Surface profile mill depths are accomplished by blasting various types and sizes of media. Non-specifications, but the estimated examples of the type and size media that will achieve different mill profiles are below:

|

2 Mill Profile |

3–4 Mill Profile |

|

24–36 grit aluminum oxide |

14–16 grit aluminum oxide |

|

24–36 grit garnet |

16 grit garnet |

|

24–36 grit silicon carbide |

16–24 grit silicon carbide |

|

G-40 steel grit |

G-25 steel grit |

|

S-230 shot |

S-330 shot |

Paint Adhesion. Common tests for coating adhesion are: Cross Cut Pattern test (covered in specification ASTM D 3359-07), Pull-Off test (covered in specification ASTM D4541-09E1) and Scrape Adhesion test (covered in specification ASTM D2197-98).

Originally published in the February 2016 issue.

RELATED CONTENT

-

Mastering Sanitary Stainless Steel Finishes

Here’s a primer on the types of finishes required for equipment used in sanitary applications.

-

How to Select the Right Flap Disc

Consider these five variables to determine what fits your application.

-

Polishing vs. Buffing: What's the Difference?

Is polishing the same as buffing? Mechanical finishing expert, Pat Wenino, explains the differences between the two processes.