Medical Coatings Can be the Cure for Plating Shops

Medical Coatings Help Artistic Plating in Milwaukee Focus on the Future, and the transformation has also coincided with the emergence of John Lindstedt’s son, Matt, as the future leader of the company.

#medical

History has a funny way of repeating itself, and that’s especially true at Artistic Plating, a 4th-generation- owned finishing job shop in Milwaukee.

John Lindstedt took over the family business in 1989 when his father, James, retired from the company he founded with his own father, Harry, back in 1948. John Lindstedt began moving the company into the “future,” shifting the focus from retail refinishing into more decorative industrial accounts. It eventually became one of the largest platers within the plumbing sector as well as other high-end decorative markets.

Featured Content

But when the plumbing industry shifted to physical vapor deposition (PVD) and began to move the majority of the finish work offshore, Artistic Plating had to transition its focus to new industrial accounts. This required becoming even more flexible with its processes to accommodate a wider spectrum of difficult-to-plate substrates and meet the needs of a growing industrial customer base.

“We decided we weren’t going to focus on the plumbing market anymore,” Lindstedt says. “So we had to take the direction of the company from being a high-end decorative finisher to a flexible job shop capable of servicing a wide industrial base of customers. This brought about a much greater diversity of basis materials and many difficult-to-plate alloys.”

Business Transformation

Whereas at one time the plumbing market accounted for as much as 65 percent of the company’s business, it is now less than one percent of Artistic Plating’s sales. The transformation has also coincided with the emergence of Lindstedt’s son, Matt, as the future leader of the company.

An Air Force veteran with a background in mechanical engineering, Matt joined the company full time in 2003 as the engineering manager. After working in this position for several years, he transitioned into the sales manager position to succeed the retiring sales manager who had been with the company for 15 years.

Matt admits it was a big change.

“I wasn’t comfortable with this new position at first,” he says. “It took some time to realize that what we had been doing in the past had to be the past. We needed to refocus as a company on markets that fit our core competencies and were not as prone to offshoring. We also had to be willing to stretch as a company to gain processes, certifications and capabilities to service the needs of those markets.”

Just as his father had learned some 15 years earlier, Matt had to look to the future at what markets and process capabilities were needed for Artistic Plating to continue to grow as a successful business.

“One of the things I knew we had to do was move into markets that were not easily outsourced overseas,” Matt says. “Focusing on non-commodity markets and working to be a value-position finishing company that brings surface engineering expertise to our customers is where we have been successful.”

Recession Takes a Toll

It wasn’t an easy road, though. The recession of 2008-2009 hit everyone hard, and Artistic Plating was no different. A 41 percent drop in sales between the first quarter of 2008 and 2009 resulted in a 10-percent pay cut for salaried employees, mandatory reduction in hours for hourly staff and significant reductions in capital spending.

During this time, margins on any job became tighter and tighter as companies were underbidding work just to cover their overhead.

“We had to continually find ways to do more with less during that period,” John Lindstedt says. “I couldn’t have been prouder of the way our people responded to work through the greatest recession of our lifetime.”

It was during this time that it became even clearer to Matt that the company had to grow into a diversity of markets that were not as affected by economic fluctuations.

“During the recession we really began to market as a company and look at what we had to do to offer best value to our targeted markets and customers,” he says. “We didn’t want to be the cheapest plater but rather the company that offered best value and brought over 60 years of surface engineering expertise to our customer’s specific designs and applications.”

One of the key markets that Artistic is committed to is the medical market.

“Our first medical customer actually dates back to the 1960s,” Matt says. “Our wide range of finishing capabilities, coupled with the ability to plate very small parts on the wide range of exotic materials used in the industry, are a great fit.”

Targeting Medical Coatings

Using a targeted marketing approach as well as John’s metallurgical skills to further the company’s progressive plating chemistries and techniques, Matt has positioned Artistic Plating as one of the top sources to provide medical metal finishing services on nearly any alloy, including nickel-cobalt, tungsten, Inconel, Monel, Hastalloy, Kovar, beryllium and tellurium copper, most any stainless steel, lead, molybdenum, and tantalum, among others.

“Currently, our biggest finishes within the medical market are electroless nickel, gold, powder coating and passivation,” Matt says. “We continue to keep an eye towards finishes such as electropolishing and are very interested in a potential alternative to hard chromium, as this finish is used extensively within orthopedic applications.”

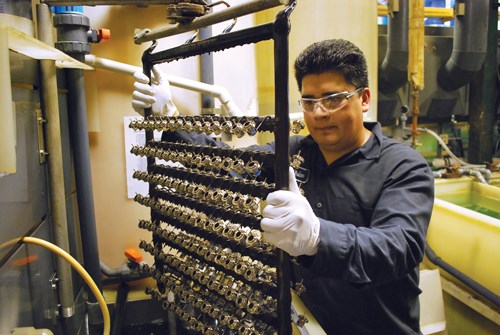

One of the capabilities that Artistic Plating continues to focus on has been the niche of smaller medical parts.

“We’re continually pushing in that direction and developing techniques and tools to continually handle smaller and smaller medical parts,” Matt says. “The other advantage we have is that we can plate on a wide range of alloys, and we are extremely flexible as a company willing to install chemistries as they are needed for specific applications and customers. We also have focused extensively on handling, cleaning and packaging of parts, which is a key requirement for most of our medical customers.”

Working with unique substrates in demanding applications can be a challenge for even the best job shops, which is why a good team of suppliers and advisors is often the key to success.

Artistic Plating has a good working relationship with the team at OMG Electronic Chemicals, LLC, which consults with John and Matt Lindstedt on what works best for certain alloys and other unusual call-outs for specific medical coatings.

Critical Service Needs

John Lindstedt, who has served the plating industry at various local and national levels with his work with the National Association for Surface Finishers, says he never chooses a supplier or vendor based solely on price because of how critical service and consultation from the vendor is for the company’s applications.

“To me, it’s about the service a supplier can provide” he says. “We have an extensive analytical lab at Artistic Plating with two full-time graduate chemists, and we do nearly all of our analytical work in-house. But the day often comes when we get things that are really bizarre. It’s always helpful to have a second perspective on a finishing problem.”

That’s when John and Matt ring up their partners at OMG to throw around ideas.

“I’ll call OMG and explain what I have and ask for their thoughts and ideas,” John says. “That’s the time when I expect that supplier to be here. That’s when they earn my business.”

It’s often a case of getting a second opinion, which is appropriate when working in medical coatings. The Lindstedts want to validate what they think will work best, and suppliers like OMG often give them their best, honest opinions.

R&D Facilities

Artistic Plating has working R&D relationships with several tooling manufacturers that have resulted in numerous patented designs, including specialized techniques in medical plating services such as oscillatory, minimum-part-movement (MPM) and vibratory plating barrel techniques.

The company also offers specialized packaging as an integral component of its medical plating services, including vacuum seal, nitrogen backfill, packaging for breathing circuit gas (BCG) service, customized boxes and partitioned trays.

Matt believes that the company’s continuing focus within the medical industry will help ensure that Artistic Plating can weather future economic storms, because demand for medical components is consistent, regardless of the state of the economy.

Artistic Plating also has focused on other key markets, including the defense market and the power transmission industry, expanding its base to companies outside its geographical areas.

“We have serviced the power transmission market to varying degrees since the 1960s, but we never focused specifically on growing our work in that industry outside of the Milwaukee and Chicago regions,” Matt says. “As we have continued to gain focus on what we do best, we have expanded our growth within the power market outside of our local region.”

Two Companies in One

Matt says Artistic Plating has basically become two companies in one.

“In our commercial division, we continue to grow our industrial base in power transmission/distribution, defense, ammunition and other industrial markets,” he says. “Whereas within our medical division, we continue to focus on expanding our capabilities and processes to better align with the specific needs of that market.”

One of the changes Matt has brought to the table is sitting down regularly with Artistic Plating group leaders and analyzing the company both tactically—what do they need to do immediately on the jobs they have in the pipeline—and then strategically, focusing on where the company is headed and how to get new business.

“It’s too easy in the metal finishing job shop to get caught up in the day to day,” he says. “We have changed the culture within our company to realize that strategic thinking is the most important part of what we do. I could not be more excited today about how far we have come as a company, the direction we are headed and the future expansion that is on the horizon.” n

For more information on Artistic Plating, please visit Artisticplating.net; for information on OMG Electronic Chemicals, please visit OMGi.com.

Gaining Control with Plating Automation

While Artistic Plating’s John and Matt Lindstedt have years of first-hand knowledge on running their shop, they still decided to build a sophisticated software program to help them and their staff control the plating operations at their plant.

Tapping into his college degree in mechanical engineering, Matt worked with the company’s partners at Honeywell to build a centralized Supervisory Control and Data Acquisition (SCADA) system that ties in all the plant’s programmable logic controller units for a single “point of control.”

“We were tired of stand-alone PLCs and programmable controllers not functioning properly and of the time that was required by our maintenance department to keep those systems working and in control of our processes,” Matt says. “When we overhauled our primary waste treatment system in 2005, we started looking at a better way to control all of the points within the system. That is when our eyes were opened to the capability of modern PLC and SCADA systems.”

Once they saw how well it worked in their waste treatment system, they began to branch the system out to control more and more of their facility.

“That trend continues today as we are constantly finding new ways to automate and control more within our facility,” Matt says. “The concepts of control are completely based on our design, but they are often worked out through iterative steps until the final product works in the exact manner that we want it to.”

Artistic Plating primarily uses Honeywell HC900 PLCs but also have some Omron and Allen Bradley (Rockwell) SLC50 units tied in. The access to the system is through a Windows server either locally, through remote PCs throughout the plant, or through a VPN session with screens that are customized to display the data and information that the company chooses.

Currently, the system does the following:

Controls the temperature set points and scheduling of all of the lines.

Monitors bus bar temperatures, facility HVAC controls (make-up air, exhaust settings, facility temperature), the main plant boiler, air compressors and bake ovens, and controls of automated lines.

Monitors all aspects of waste treatment systems, such as level control, automated pump control, and ORP and pH controls, among others.

The biggest benefits of the system, besides the automated controls, are the history trends.

“We now have extremely tight process control and maintain history on exactly where any of the control points were in the past,” Matt says. “This is not only a huge factor for many of our more sophisticated customers, but also for troubleshooting by our maintenance department.”

For example, Artistic’s staff gets real-time status updates on all process values in its facility, and they are available from anywhere in the world through a VPN session, which can be alarmed as needed for critical components. The team can receive email alerts if any of the make-up air units have a flame-out condition in the winter.

Matt Lindstedt also likes that history trends are available for any control point within the system, and that it has excellent flexibility for expansion of additional set points within the facility, such as integrating EN controls into this system for trending.

“We have true and accurate control of critical operational parameters such as tank temperature, and we have saved tens of thousands of dollars on energy and chemistry since switching to this system,” he says. “Set points are maintained rather than overshooting and undershooting constantly. This saves energy for heating and chemistry in waste treatment.”

RELATED CONTENT

-

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.

-

Sizing Heating and Cooling Coils

Why is it important for you to know this?