‘Non-Traditional’ Goes Mainstream

Once unusual mechanical finishing processes are becoming more common

Less than 20 years ago, the Burr Edge & Surface Finishing Group of the Society of Manufacturing Engineers (SME, Dearborn, MI) recognized three types of mechanical surface finishing and deburring processes: Buff, Brush, and Polish; Vibratory Burnishing; and Barrel Tumbling. Centrifugal deburring and chemically accelerated centrifugal deburring had been around long enough to be accepted in this group; anything else was lumped under the umbrella of “non-traditional.”

Of course, these older, accepted techniques have served our industry well up to the present. They have constantly incorporated improvements including fixture control, precision burr and stock removal, use of computer electronics, innovative and improved media and chemistries, and in-process quality control. Like machining and metal forming and casting techniques, these finishing processes have continued to develop to meet the demands of both society (ie: worker safety and environmental regulations) and a constantly improving end product.

Featured Content

But processes formerly classified as “non-traditional” have quietly moved into the mainstream, at least in some applications. Some of the factors that have brought this about include the need for longer mold life in both metal casting and plastic injection applications, longer tool life, faster job change-overs and small batch processing with shorter delivery times. Another factor is more wide-spread adoption of Lean Manufacturing philosophy and techniques. Wastewater management, water usage and recycling are additional driving forces.

But probably the largest boost to adoption of these formerly “non-traditional” processes has been the birth of micro-manufacturing and miniaturization. Major segments of industry that have accepted and welcomed the non-traditional processes include aerospace/aviation, electronics and medical device manufacturing.

Even in these industries, surface roughness requirements as low as 0.5µm average roughness (Ra) with tolerance needs in the area of ±0.0001–0.00005 inch, plus reproducibility for production runs, may not be the norm, but several of the newer finishing processes can deliver that kind of precision. These include abrasive flow machining (AFM), orbital abrasive flow machining, electro-chemical machining (ECM), electro-chemical deburring (ECD), micro-electro-chemical machining, thermal energy method (TEM) and thermo-diffusion, waterjet and laser machining and cryogenic processing. Here’s a look at the current state of some of these finishing technologies.

Abrasive Flow Machining

Anyone who has ever seen a ball of Silly Putty bounce can readily grasp how combining this material with assorted varieties of fine abrasives could result in development of a controlled polishing and burr removal tool.

Of course, the current carrier material science for abrasive flow machining is a bit more sophisticated than the “Silly Putty” carriers available in the beginning, and is much more readily removed from finished parts. Selecting the polymer carriers used to move the chosen abrasives over surfaces, in and out of holes or back and forth inside tubes is in itself a science. Developments in carrier density, and the size and shape of the abrasive media chosen, have allowed AFM to expand its range of work materials to include aluminum alloys, zinc die-cast alloys and even plastics.

At the other end of the spectrum, high-strength alloys for aerospace and automotive applications are viable targets for surface smoothing. Used to smooth the IDs of fuel system components, AFM can provide improved fuel efficiency—a key driver of both automotive and aerospace technology. The process can also remove surface stresses and improve fatigue life while providing surfaces with improved resistance to hydrogen embrittlement from any follow-up wet processing requirements.

Abrasive materials used for these applications are usually silicon carbide, boron carbide, or diamond. Suppliers of AFM technology include in their products the cleaners and methods needed to treat part surfaces for subsequent chemical and electrochemical operations such as plating.

Currently, use of AFM is limited to holes with depth:diameter ratios of 8:1 or less. The process can improve the surface finish of investment castings from 120 to 16 µin. A Ra of 2µin. is typical, not a rarity.

Into Orbit

Combining newer AFM carrier and abrasive technologies with circular and/or back-and-forth motion has resulted in wider applications for the technique, which is called Orbital Abrasive Flow Machining.

As the name implies, the process uses polymers with sufficient elasticity and plasticity to handle the circular or other movements. It can provide even better surface roughness reduction than AFM alone—in some cases, 20-30× better. Average roughness of 0.01 μm have been achieved.

In the medical industry, the life of an artificial hip has been extended dramatically using orbital AFM. The canopy of a jet fighter that once required thousands of man-hours of precision polishing is now polished in 80 hr to a Ra of 2 μm, and the canopies are interchangeable!

At the other end of the manufacturing scale, fine finishing of molds used for blow molding tens of millions of plastic water bottles has been reduced from hours to minutes. The required surface finish is 4 μm Ra.

Electro-Chemical Processes

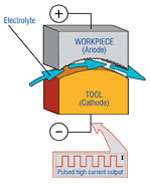

Electro-chemical machining (ECM) is based on the principle that using controlled conductors of voltage (higher than those found in electroplating, and more in the range of electro-polishing) along with advanced tooling in both the metallic source of the electrode and fixture/masking, can result in the ability to process many parts rapidly.

ECM technology has progressed from just being able to knock off large burrs from castings and forgings to providing precision stock removal in the 0.0005–0.02 inch range. At the same time, the process improves surface roughness by factors of 5-10× or better. It also deburrs internal passages with accurate and repeatable edge conditions.

ECM cells with the capability of reaching production rates of hundreds of parts/hr are readily built into the equipment. An example of this is a system that removes burrs from 44 holes on eight passenger-side air bags in less than 10 sec.

Processes similar to ECM include micro-ECM and electrochemical deburring (ECD). The ECD process actually predates ECM—20 years ago, the precision electrochemical process was specialized for deburring. Technical advances in fixture versatility, miniaturization of tools to match the hole sizes involved and new masking materials has made the term ECD inadequate for describing the capabilities in and around not just a hole but scores of holes. Electronic control is such that spacing of 0.0002 inch between part and fixture are commonplace.

Both ECM and ECD use similar simple components. These include a machine housing, a control system, a DC power supply, an electrolyte system, tooling and a filter. The footprint for these components is surprisingly small. Barring use of some exotic metal or plastic work material, waste disposal and/or waste treatment are a minor requirement or, more often than not, nonexistent.

Yet another cousin to these processes is micro-ECM, which has been enabled by improved filtration processes, chemical formulations and electrode metallurgy. The major application for micro-ECM is machining grooves in fluid dynamic bearings. Grooves from 3-30 µm thick are produced accurately and repeatably in a few seconds, while the workpiece is not subjected to any thermal or mechanical stress. As a result there is no physical or chemical change to the properties of the material. The only limit is the ability to produce or procure the cathode tool needed to do the job.

Production of internal passages a few microns deep by 10-100 μm wide is also possible using micro-ECM. In one application, grooves 3-30 μin. are produced in a 4-sec cycle time. In yet another application, micro-ECM produces more than 40 grooves in a 0.200-inch diameter bore in 3.5 sec.

ECM, and similar processes such as electro-chemical deburring (ECD) and Micro-ECM, have no tool wear and consume no chemicals. They can deburr and smooth many features on complex parts, such as internal edge radii, tapers, and rifling not separately, but rather at the same time.

Thermal Energy Method

The thermal energy method (TEM) removes burrs and flash from all part surfaces. Blind holes, intersecting surfaces, and bulk manufacturing of conductive small parts are all candidates for TEM.

In TEM, a pressurized mixture of oxygen and a combustible gas (methane, for example) is added to a chamber with parts. The gas mixture is ignited by a spark mechanism, and a short (0.1-0.2 sec) shock heat wave literally vaporizes the thin metallic flash or burr. Meanwhile, the main body of the part soaks up the superheat resulting from the process and diffuses it into the mass of the part.

The reaction is thus limited to the thin metal that is vaporized. The location of the thin metal as a burr, external or internal has no bearing on the ability of the process to perform.

How high do temperatures go in TEM? In the area of 3,000-4,000ºF. And where does the vaporized metal go? It is deposited as a loosely adherent and uniform molecular layer skin on the rest of the surface of the parts. The good news is that the manufacturers of this type of process have worked with surface cleaning specialists to develop technology that results in parts that are cleaner than when the operation started.

Initially, the engineering minds that developed this technique worked with a turntable and rigid fixturing that limited the number of pieces per cycle. Equipment is so encased that there is little more than a “pop” when ignition occurs. Today, TEM is an excellent tool for bulk processing miniature parts that would be distorted or bent out of shape if subjected to other methods of stock removal.

Thermo-Diffusion

The simple act of incorporating heat into the sherardizing process (a form of mechanical plating) has resulted in development of another process tool for metal finishing engineers.

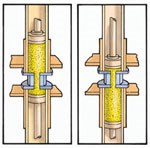

Like sherardizing, the process starts when zinc powder and the parts to be coated are sealed into a cylinder. This cylinder is loaded, on rollers, into a heat treat oven, at approximately 450°C for 3–4 hr. During this time, the zinc vaporizes and penetrates into the smallest cracks, while evenly coating the part with the desired, coating thickness.

The developers of thermo-diffusion say the corrosion protection thus given to parts far exceeds that of either hot-dip or electro-galvanize coatings. Vacuum and filtration systems make the recycling of unused zinc an appealing bonus.

Waterjets and Lasers

Making deep, small-diameter holes accurately and cutting small parts without generating a heat-affected zone are just two of the possibilities available with waterjet cutting. The current crop of waterjet machines use improved control software, fine nozzles and considerable improvements in high-pressure pump technology to cut, for example, 1.2-mm diameter holes in 4-mm thick stainless steel. This same technology allows cutting of a 1.3-mm hole in aluminum.

Precision turbine blades, nozzle guide vanes, shrouds and combustors from the aerospace industry with a need for not only holes without subsequent metal finishing but also a need to produce odd-shaped ports has made both waterjet and laser machining viable options for workpiece manufacture. Thin parts are the most frequently considered a target for precision laser with the same capability of production repeatability and speed.

Cryogenics

Generation of surface heat from the interaction of the part and the tool can have detrimental chemical and/or mechanical side effects on very delicate parts. In these cases, parts can be deflashed or deburred using cryogenics— freezing either the tool or the part using liquid nitrogen to temperatures of approximately -320°F.

Two factors that limited use of cryogenics for part processing were handling of both the part and the tool and finding a material that would house and hold the tool itself. Both of these elements are fast disappearing as an obstacle.

In cryogenic deburring, parts are placed in a chamber, exposed to liquid nitrogen temperatures, tumbled and blasted with a polycarbonate media. Burrs “freeze” very quickly and become brittle. The tumbling action, combined with the impact of the media, removes the burrs without damaging the part itself. The process is said to be well-suited for die-cast metal parts, complex plastic or rubber parts, medical components parts and micro-electronics parts.

Far from damaging workpieces with heat, cryogenic processing can actually create beneficial effects in some work materials. Cryogenic tempering uses liquid nitrogen temperatures to modify the microstructure of metal for more stable, wear-resistant parts with fewer residual stresses.