Some Buffing and Polishing Basics

Some general information and pointers on polishing and buffing...

#basics

Buffing and polishing using wheels and compounds is somewhat like using wet and dry sandpaper, only much faster. Instead of using elbow grease, you use the power and speed of an electric motor. The face of the wheel is the "sanding block," which carries a thin layer of compound (sandpaper) to the part.

The objective of buffing is to make a rough surface smooth; however, every part does not have the same finish and will need to be worked differently. Some divide buffing into satin finishing; cut-down buffing for preliminary smoothness; and cut-and-color buffing for smoothness and luster.

Featured Content

Satin finishing produces satin, brushed or butler finishes on metals. Satin finishes are produced by first buffing the work piece to a bright finish and then dulling it to give it a softer, brushed look. These finishes are applied using an abrasive and glue mix or greaseless compounds.

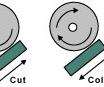

Cut-down buffing makes surfaces smoother by removing scratches and other marks caused by previous operations. The workpiece should be moved against the direction of the wheel, using a medium to hard pressure.

Color buffing further refines the surface and brings out maximum luster. The workpiece should be moved toward the direction of the wheel using medium to light pressure.

Buffs are created from cotton (muslin), canvas, chamois, sisal or string. They may be loose, sewn, ventilated or pocketed. The following list provides descriptions of several types of buffs:

Loose buffs have several plies of material with a row of sewing around the center hole. These buffs are most often used for the final buffing operation prior to plating. Because the wheel is not tightly stitched, it will collapse, allowing cotton to get into awkward places more easily. The best loose buffs are 100% cotton.

Sewn buffs have sections of cloth sewn spirally, concentrically, radially, square stitched or in a crescent pattern that runs from the center of the buff to the edge. The stitching can be as tight as 1/8 inch to single rows that are 2-3 inches apart. Alternatively, the buffs can be spirally sewn, which is the most common type of sewn buff. These buffs are usually used for buffing nonferrous metals. They can also be used as coloring buffs. The wheel is harder and more pressure can be exerted. This is useful when cutting metal.

Bias-type buffs are probably used most often in the industry. The cloth is cut at a 45-degree angle, wrapped about a drum and squeezed into a clinch ring. These buffs combine flexibility and cutting power. A weaving pattern (spacing) between the sections provides for natural ventilation. Bias buffs can be customized to work with various sized parts and to provide degrees of cut and color.

Folded (pocketed) buffs have disks of material folded to form pockets that hold compound. These buffs are mounted in one direction for cutting and mounted the other way for coloring. They provide fast cutting and good flexibility.

Sisal buffs are made from a strong cloth and may be plain or treated, full disk or ventilated with a center metal clinch ring. These aggressive buffs provide polishing and cutting action and are most often used on ferrous metals. However, they can be used on nonferrous metals as well. Sisal buffs soften and become flexible from the heat generated during the buffing operation.

String buffs are soft and flexible for use on plastics or precious metals to avoid leaving buff marks. These buffs are also good for coloring precious metals since they leave no buff marks.

Buffs can have up to 100 layers of cloth or plies. They can have soft, medium or hard densities, which refers to the thread count of the cloth. A higher thread count indicates a stronger, harder cloth with greater cutting ability.

Buffing wheels have a variety of designs, and run at speeds of 5,000 to 8,000 sfm. Each wheel should run for a few seconds prior to use. Also, buffing wheels have safe and unsafe areas. The safe area rotates away from the work piece and toward the operator. The unsafe area rotates toward the work piece. The work piece must be applied only to the area of the buff that is rotating away from the work piece. Objects thrown away from a buffing wheel travel at high speeds, which could result in serious or potentially fatal accidents.

Buffing compounds actually do the work, however, not the buffing wheel. Do not apply compounds after the work piece or alone since this wastes material. When you apply the compound to the buff prior to the work, you use the work to force the compound into the buff. This is more efficient and speeds buffing times.

Compounds are composed of fine abrasive fillers (aluminum oxide, emery, silicon carbide, diamond, boron carbide, zirconium, etc.) and greases, oils or wax. There are several types of and uses for buffing compounds.

Tripoli buffing compound has been around a long time and is one of the most popular compounds for cutting down and producing a high luster on nonferrous metals. There are several types of Tripoli compounds, depending on the type of finish desired and on the substrate.

Chrome rouges are used for buffing chromium and stainless steel. The cut varies from mild to fine and sharp. Rouges are made of mild oils and greases with alumina abrasive.

There is also jeweler's rouge. Red rouge brings out a high color on gold, silver, sterling, platinum and brass. White rouge produces a brilliant finish on chromium, stainless steel, steel, brass and aluminum. Green rouge is used for fine color buffing on all types of metal.

Steel compounds vary in color from nearly black to light gray depending on the composition. These compounds are used to buff iron, steel, stainless steel and some aluminum and brass castings. Steel compounds vary in cut depending on the kind of sisal buff used and the amount of grease in the compound. Stainless steels can be easy to buff or nearly impossible depending on the condition and type of steel. When buffing stainless, use a dry- or medium-dry compound on untreated full sisal or laminated sisal buffs.

White coloring compounds are used for buffing nonferrous metals that are in good condition to produce a mirror-bright finish. It can also be used on copper-plated articles when a regular Tripoli compound would be too severe.

Liquid buffing compounds are used with automatic machines in high-volume production situations. However, they can also be used with semi-automatic systems and hand-buffing operations. Spray guns are used to apply liquid compound pumped from a drum.

The same abrasive powders are used in spray compositions; however, the binders are different. Binders are used in oil solutions or water emulsions so that they are fluid at room temperature.

Polishing

Polishing is not a precision operation. It is used to remove metal and produce fine-scale abrasion. Friction generates high temperatures that can soften the surface of the workpiece. Polishing, which usually involves several stages, precedes buffing.

Polishing stages begin with a rough polishing stage using abrasive grit sizes of 36 to 80. Second stage uses abrasives sized from 80 to 120. For the first two steps the wheels are used dry. The third stage uses 150 size and finer grit. In this stage, the wheels are slightly worn down and coated with oil, beeswax or a similar substance. This step is actually part polishing, part buffing, since more abrasive is usually added with the grease.

Polishing wheels are made of muslin, canvas, wool or leather. The most frequently used types are made from sections of sewn cotton buffs held together with adhesive. These are the most versatile and have a moderate cost. The hardest wheels are individual canvas discs cemented together. The softest are muslin discs sewn together.

Pressed felt wheels have densities that are extremely hard as well as extra soft. These wheels are used when uniform density is required over the entire surface of the wheel. The felt face contours easily to fit irregularly shaped parts.

Leather-faced wooden wheels are used on flat surfaces when a minimum of flexibility is needed. These types of wheels are popular with gunsmiths and manufacturers of cutlery. If greater flexibility is needed, sheepskin is used.

Compress wheels are created by attaching pieces of leather or woven fabric endwise to a rigid center section of steel or plastic so the cloth edges are perpendicular to the side of the wheel. Since there are no seams, more precise polishing can be accomplished.

Wire wheels can be constructed from stainless steel, brass or nickel wire. These wheels remove rust, scale, burrs and coatings, as well as providing a satin finish or highlighting oxidized finishes on brass, copper or silver.

Most polishing operation speeds range from 5,000 to 7,500 sfm. High-strength steels and stainless steels are polished at the higher rates; however, excessively high speeds may burn workpieces. Wheels that are more rigid are used for coarser polishing where rapid metal removal is needed. Rigid wheels are also used when the surface is regular and not contoured or irregularly shaped. Wheels that are more flexible are better for polishing and use on irregular surfaces.

Suggestions and pointers

- Wear the proper protective clothing: safety goggles, apron, gloves and respirator. Do not wear loose clothing.

- Do not rush into any polishing or buffing job. Go slowly, and handle complex parts carefully.

- You should also know the rpm of your system so that you can calculate the surface feet per minute (sfm) the wheel is traveling. ¼ × diameter of the wheel x rpm = spm.

- Use a firm yet flexible grip to hold the workpiece a little below the wheel's center. This is a safety precaution. If the wheel grabs the workpiece, it will throw the part away from you.

- Since parts are moved back and forth across the buff or wheel, the buff/wheel should not be wider than the part. Moving the piece back and forth also releases heat.

Buffing and polishing may seem like simple operations. You simply hold the work piece to the wheel until it shines. But there is an art to it, and you need to know the basics before you can make rough surfaces smooth and dull surfaces shine.

RELATED CONTENT

-

Touch-up Options for Powder Coated Parts

Is it true that powder coating cannot be touched up? Powder coating expert Rodger Talbert offers options for powder coating touch-ups.

-

Deoxidizing Aluminum as a Pretreatment

This important first step can help prepare the metal for subsequent surface finishing.

-

Zinc Electroplating

Choosing the best process for your operation.