The Right Stuff

How to Get the Ideal Powder Finish for your Parts

#curing

Experienced finishers know that the protective value of a coating depends on many variables in addition to the specific topcoat material. The total process determines coating fitness, not just the material itself. Each process step is important to the protective value or expected life of the finished coating, including:

- Substrate material, condition and soils

- Part preparation

- Powder coating material(s)selection

- Powder coating application control methods (applied thickness, curing, etc.)

- Technical competence of the coating technicians (training)

- Equipment condition (maintenance, calibration)

- Film thickness and completeness

- Product design and fabrication

- Environmental conditions where the product is used

- Protection and maintenance

Featured Content

A correctly applied organic coating provides a barrier to harmful environmental conditions and limits the ability of harmful corrosive agents to penetrate the coating through to the base metal. A successful coating must be a completely continuous film with a tight bond to the pretreated metal substrate. Any imperfections in the barrier become a focal point for development of corrosion and a breakdown of the protective structure.

The question is, what coating process, material and process controls need to be used to protect a given substrate material to some defined performance level? The answer to that is established by providing a few answers to some other critical questions:

- Does the product need to be coated to some existing standard?

- What is the primary purpose of the coating?

- What are the decorative expectations for the product?

- What are the functional expectations for the product?

- Will the product have a specific warranty for coating?

Substrate Review

Powder can be applied to a variety of metal substrates, each of which has distinct characteristics that influence the pretreatment and coating methods used. Substrate properties that impact selection of pretreatment and coating processes include the metal type, surface condition, part geometry, metal mass, product design and fabrication.

In addition to an understanding of the base metal composition, it is critical to understand the condition of the metal, including presence or absence of mill scale, laser or weld spatter, previous organic coatings, corrosion or oxidation, oils and lubricants, die-cast release agents, rust inhibitors and coolants.

Part design features such as overlapping seams, sharp edges and welds should be considered in coating process development. Things to avoid include pockets in the part that can cup moisture during cleaning, sharp edges that will be hard to cover with sufficient film thickness, overlapping seams that create places to trap oil and water and leave areas that cannot be coated, dissimilar metals in the same construction that can promote galvanic corrosion, deep recesses that cannot be coated and holes or machined features produced after coating.

Oxidation, scale, carbon and welding slag and spatter must be removed before finishing. Stitch welding should be avoided because it creates areas that are hard to pretreat, hard to cover with powder and may trap water. Materials like expanded metal with sharp edges should be avoided or the edges should be mechanically rounded.

Service Conditions

Another key factor that influences how the part will be processed is the conditions in which it will be used. A product destined for use in an aggressive outdoor environment will require a much higher standard of corrosion protection than one located in a controlled indoor environment.

The Powder Coating Institute (PCI; The Woodlands, TX) defines seven atmospheric classifications that can be used in process selection (Table 1).

|

Table 1 PCI Atmospheric Classifications for Powder Process Selection

|

||

|

Classification

|

Definition

|

General Description

|

| 1 | Very Low Performance Specifications or Expectations | Effective decorative finish; not suited for exterior or harsh environments |

| 2 | Mild Interior | Effective decorative finish; not suited for exterior or harsh environments; may be used indoors or in semi-protected areas without climate control |

| 3 | Moderate Interior | Slightly higher degree of performance; some corrosion resistance; may be subjected to some condensation and humidity |

| 4 | Quality Interior |

Some warranty and expectation for long-term quality appearance; some corrosion resistance required |

| 5 | Mild Exterior | Used outdoors, some UV resistance is required; limited corrosion protection; mild outdoor environments |

| 6 | Moderate Exterior | Substantial UV resistance and long-term performance; possibly extreme environments & corrosion challenges |

| 7 | Architectural, Marine, Industrial, Tropical |

Substantial UV resistance & corrosion resistance; used in very harsh environments |

Surface Preparation

Surface preparation includes any operation or combination of operations performed on part surfaces to clean and remove physical defects and surface contaminants before application of an organic finish. Improper pretreatment is the leading root cause of premature catastrophic coating failure. Atmospheric service conditions dictate the type of surface preparation that should be selected in order to meet the performance expectations of the product in that particular environment.

Some types of soil are best removed by mechanical abrasion. Mechanical surface preparation for coating uses abrasion to remove surface defects and contaminants and establish a surface profile that is satisfactory for good mechanical coating adhesion. Methods such as sanding or abrasive blasting remove soils and leave a rough surface that enhances coating adhesion.

Steel substrates must be cleaned to remove shop dust, rust inhibitors and other organic soils as well as weld spatter and other inorganic soils. Depending on condition, it may require a combination of mechanical and chemical preparation processes to achieve the surface condition needed for coating application.

Iron phosphate is the most common chemical conversion coating currently used for powder coating. The process has been around for a long time and is effective for indoor and some outdoor applications. Reasonably simple and cost-effective to use, iron phosphate does not add significantly to corrosion resistance if the coating is broken but it does improve coating adhesion and life of the product.

Zinc phosphate is available for more extreme conditions. Zinc provides improved adhesion and a sacrificial layer that will help prevent the spread of corrosion. Zinc phosphate also costs more than iron phosphate, and the heavy metal and heavier sludge mean more pressure on waste treatment efforts. Chromium can be used with zinc to further enhance corrosion resistance, but addition of chromium also adds to waste issues. Table 2 compares the characteristics of iron and zinc phosphates.

|

Table 2 Comparison of Iron Phosphate and Zinc Phosphate Pretreatments

|

||

|

Characteristic

|

Iron Phosphate

|

Zinc Phosphate

|

| Average Coating Weight, mg/ft2 (g/m2) | 15–90 (0.16–0.97) | 50–500 (0.54–5.4) |

| Surface Structure | Amorphous (requires less powder to cover) | Crystalline (requires more powder to cover) |

| Paint Adhesion |

Very good (normally will not fracture even if metal is bent) |

Very good to excellent (crystalline layer may fracture if metal is bent) |

| Salt Spray Resistance (5%), hr |

200–500 | 600–1,000 |

| Relative Cost | Moderate | More expensive |

| Sludge Formation | Moderate | Heavy |

| Solution Life | Very good | Very good |

| Control of Solution | Very easy to control (1 or 2 tests, 1 product) | Difficult to control (3–4 tests, products must be balanced, pre-conditioning must be controlled) |

| Equipment | Same as other spray washer stages | Tanks should be stainless steel, sludge separation equipment needed |

| Maintenance | Minimal |

Higher (sludge handling) |

Alternatives to iron and zinc phosphate have emerged in recent years. Based primarily on zirconium oxide, these newer technologies provide a good coating with no process heat required and far less sludge. They are effective on a variety of metal surfaces and they contain little or no phosphate. These products are gaining acceptance as more companies have used them successfully and the results have been good.

Alternative pretreatments usually require stainless steel construction for the washer, and they work much better with filtered makeup water. Field experience with them is much shorter than with phosphates but the future looks good for these products.

Aluminum substrates be pretreated in the same wash operation as steel parts, but some understanding of treatment options for performance is critical. Treatment of aluminum in the same system as steel is usually accomplished by addition of fluoride to an iron phosphate solution. This works for indoor applications but it is not regarded as a high-performance treatment for parts destined for outdoor exposure. If aluminum parts will be used in an outdoor application they should be treated with a suitable aluminum conversion coating. This includes both chromium-containing and non-chrome chemistries.

Choosing Materials

Selection of the correct powder coating material, or combination of materials, for a given use is critical to the success of the total engineered finish. Applicators need to select the proper coating chemistry based on established performance goals and the end-use of the product. The key to doing that is matching resin properties to the required performance properties and carefully weighing the trade-offs.

Thermoset powder systems include epoxy, polyester urethane, polyester TGIC, acrylic and hybrid technologies that combine more than one resin system. Every powder material has a Technical Data Sheet that describes its appearance and functional properties.

Coating appearance characteristics might include color, gloss, texture and smoothness. Physical properties of the coating that can be defined and compared include film thickness, hardness, flexibility, impact and abrasion resistance, edge coverage and chip resistance. Specific environmental properties should also be identified and quantified. These include salt-spray, stain, chemical and solvent resistance; weathering; and resistance to UV and humidity.

Process Options

The ultimate durability of any finish is affected by the substrate material, pretreatment method, the coating or layers of coating applied and the process controls in place when it is applied.

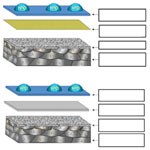

If the part does not require extreme performance, it is typical to apply a single coat of powder over a properly prepared surface. This approach is economical and effective for indoor and some outdoor applications, but a relatively thin single coating layer may not be suitable for environments where moisture and condensation are frequent.

Application of a suitable primer beneath a topcoat will provide superior protection against water penetration. It may sometimes be acceptable to abrade the surface (blast) and apply the primer without a conversion coating, but in other cases a conversion coating will further enhance corrosion resistance. Any double coat process will also improve edge coverage.

A three-coat method can be used for extreme performance requirements and to obtain superior color retention and UV resistance. In this case a clear coat layer increases UV resistance by preventing surface oxidation of the pigmented layer. All multi-coat layers should be carefully researched and tested to be sure that the products have good adhesion between layers.

Regardless of process, each coating step should be documented and controlled to provide adequate and consistent quality. Surface preparation, application and curing are all critical to the success of the final finish. Testing at each stage of the process can determine that the system is capable and keep the process under control.

RELATED CONTENT

-

Improving Transfer Efficiencies in Coating Operations

There are many methods for addressing electrostatic grounding in metal painting processes, and Tim Ulshafer from Mueller Electric says the best method for your process is a simple and worthwhile exercise.

-

Painting Over Powder Coating

How safely can they apply their wet paint over our powder coated parts?

-

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment