Winding It All into One Line

The coil coating line at MSC Walbridge Coatings can plate, paint, phosphate or apply any number of other finishes all on the same line...

Coil coating lines are monsters, and if the market you serve shrinks or desists, it could go the way of the dinosaur. That is why it is important that you vary its diet. A steady diet of just painting, electrogalvanizing or hot dip galvanizing could starve it.

Walbridge Coatings, Walbridge, OH, a division of Material Sciences Corp. houses one of these monsters and feeds it well. Although it was initially built to apply zincrometal to coils for the automotive industry, it has evolved into a system that applies zincrometal, electro-galvanize zinc or zinc-nickel, conventional zinc phosphate, dried-in-place phosphate, dry film lubricants, anti-fingerprint coatings, chrome passivation, prepaint, zinc-rich weldable coatings, metal-to-metal laminates for noise and vibration damping, and a new brushing process that produces products with aesthetics similar to stainless steel. Developing this versatility has helped Walbridge modify its system to meet customer demands and remain profitable.

Featured Content

The Beginnings

In 1980, Material Sciences Corporation built the Walbridge facility in the middle of what was once a farm field. The primary product it intended to produce was zincrometal, which is a zinc-rich primer applied to steel coils. At that time, it was billed as the largest and fastest coil paint line of its type in the world. The popularity of zincrometal increased, and the company produced more than 500,000 tons per year.

In the mid 80s, there was an influx of Japanese automobiles. The automakers were looking for sources of coated steel; however, they did not use zincrometal but zinc-nickel plated coil steel. The advantage of zinc-nickel is that it requires less current because it is applied at a lower coating weight. “In Japan, there is a limited power supply because of the size of the country," explained Dan Hughes, senior account executive. Japanese specifications for zinc-nickel are 20-30 g/meter2 per side. There is about 11-13% nickel in that coating, which offers a higher level of corrosion resistance than zincrometal had at that time.”

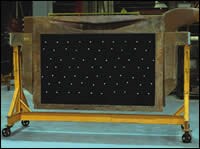

| “Command Central” where all the processes for the coil line are controlled, including temperature, line speed, bath concentration, amperage and more. |

So the U.S. automotive industry conducted research that resulted in electrogalvanizing as the finish of choice for vehicles. The research determined that this would provide the necessary corrosion protection (five years no blemish and 10 years no rust perforation). The U.S. specification is 60-70 g/meter sq/side of zinc.

Because of this new standard, Walbridge was feeling like a dinosaur facing extinction. Rather than simply become extinct, the company partnered with two steel companies, which helped Walbridge build an electrogalvanizing addition to its line. This increased the line length by a third and allowed Walbridge to supply its automotive customers with the electrogalvanized coil steel it required.

Electrogalvanizing produces a thin, even coating of zinc on the coil and is often used as a base for paint. Electrogalvanized materials can be rolled, formed, bent and curved because the coating does not peel, flake or crack. This property opens the coating up to many applications, including automotive, appliance and building materials.

Electrogalvanizing, unlike hot-dip galvanizing, forms a thin pure coating of zinc on the substrate. There are no intermediate layers composed of zinc compounds. Process temperatures are lower than those of hot dipping, making electrogalvanizing ideal for parts that could be damaged by high temperatures.

The process is performed on a continuous steel strip plating line. Two coils are loaded onto the line with the end of one coil welded to the beginning of the other coil. The coil runs through the initial alkaline cleaners and rinse, through an accumulator tower and part inspection, which is done automatically via cameras. These cameras can detect pinholes and gross defects in the body of the coil. The coil is then run through an additional alkaline cleaner with brushing. In-line tension leveling provides for shape and flatness control. The strip then travels under the plating section where it is cleaned electrolytically and rinsed. Surface activation is used to prepare the surface for the zinc plating. There is also a slight mechanical etch to create a place for the zinc to bond to.

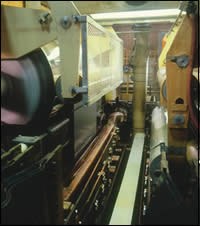

| Special anode for one of the 21 plating cells. It uses the gravitel process to flow solution through the anode. Coil is run 7-9 mm away from the anode, depending on thickness desired. |

There are 21 vertical plating cells that hold either a zinc sulfate bath or a zinc-nickel bath, depending on customer specifications. Walbridge has the capability of applying both zinc and zinc-nickel coatings. But it isn’t simply a matter of throwing a switch or transferring to another line. If zinc-nickel is called for, the vertical plating stations are pumped out and rinsed with DI water. This takes about 10-12 hours. Then the electrogalvanize solution (zinc) is pumped into the tanks. If the process is reversed and zinc-nickel is needed, the tanks are simply pumped out and no DI rinse is used. This requires about eight hours.

After exiting the plating stations, the coil is rinsed. “This is where the benefits of our system come in,” noted Mr. Hughes. “At this point, that coil strip is as pristine as it will ever be. If you take electrogalvanized coil off the line before it is shipped out for further processing, corrosion-inhibiting oil is applied. Because electrogalvanize is soft and porous, the oils penetrate down to the substrate, which can provide plenty of opportunity for airborne contaminants and dirt to take hold. I am not aware of any coil cleaning line that can get 100% of these oils and contaminants out. Because this is a continuous line, we don’t have a problem with that.”

After the rinse, if specified, the coil can be mechanically polished or not. Then a pretreatment is applied, which is the key to paint adhesion and exceptional corrosion performance. Since there is no dirt on the coil, there is good interface between the electrogalvanize, pretreatment and primer. After pretreatment, the coil goes to the coating room where primer and finish coats are applied. “We also have the flexibility to apply different coatings both in the primer and finish coating, top and bottom,” noted Mr. Hughes. “Or we can apply one coat on top and none on the bottom. It all depends on what the specification calls for.”

Differential Finishing

Differential finishes can also be accomplished with the plating side of the line as well. This is another advantage of electrogalvanizing. One side can be coated with 100g/meter sq and nothing plated on the bottom of the coil. Also, one side can be plated with a heavy zinc coating and a lighter zinc coating on the other side. “The advantage to this is in the HVAC market,” said Mr. Hughes. “One of the industry’s problems has been that when it bends these products, the zinc coating microcracks. To combat this, the industry developed softer topcoats that allowed easy bending and forming. Because the coatings are so soft, however, they are susceptible to scarring and scratching on the surface. Our operation allows you to put the zinc coating where it is needed, on the outside and a lighter or no coating on the inside and then topcoat the piece for added scratch protection.”

To accomplish this differential coating, the anodes are carefully controlled. Both plating processes (zinc-nickel and zinc) use the same titanium anodes coated with iridium oxide. These specially made anodes employ the gravitel process during operation. Solution is fed into the bottom of the rectangular shaped anode box, filling it. As solution reaches the top, it flows out and down the sides of the anode via gravity.

|

| One of 21 plating cells that the coil passes through as it is either zinc or zinc-nickel plated. |

Typically, the anodes are 9 mm away from the coil at the top and 7 mm away from the coil on the bottom. These can be adjusted to provide different coating weights. The anodes can also be shut off to prevent coating on one side or to help “even out” a coating.

In the control room, which could be called command central, one employee watches up to eight computer screens, keeping tabs on the line. From this position, he can control anodes, oven temperatures, amperage, solution makeup for each tank, line speed and a host of other parameters. All the data is backed up and stored as reference.

The laboratory is also a busy place, where different types of testing occur daily. The lab has the capacity to test thickness, coating weight, coating composition, hardness, color and gloss.

The laboratory is probably at its busiest on days when Walbridge runs zinc-nickel with an organic coating. Large automotive manufacturers use the coils for fuel tanks. This finishing sequence started in the early '90s. The fuel tanks are designed to be compatible with various fuel blends and achieve a certain corrosion life. It is an interior and exterior coating. “This is when we really began using the full scope of the line,” said Mr. Hughes. “After zinc-nickel plating, the coil is rinsed, run through pretreatment, sealed in a chromium or non-chromium seal and then we apply an aluminum-rich epoxy thermoset paint, cure it, quench it, apply a soap-based dry-film lubricant and wrap it up. The soap-based dry-film lubricant helps when the tanks are drawn, since it is a really deep draw. This is one of the first products that used the full capabilities of the line.”

Changing Markets

As time progresses, markets change. Although Walbridge is still coating fuel tanks, it is looking for more “food” for its extensive coil coating line. “You start to look at the line and you understand what I like to call economies of scope,” explained Mr. Hughes. “This line has the ability to produce a multitude of products on the same line by interchanging various process steps. You can satisfy numerous material needs in diverse markets. That is what we are attempting to do here.”

One endeavor is a brushing process to zinc-nickel plated steel that simulates the aesthetics of stainless steel. This is a proprietary process Walbridge developed chiefly for the appliance industry. In the appliance industry, 85% of the units (refrigerators) are white, black and bisque. The other 15% are stainless steel. The popularity of stainless steel has grown considerably in the past four or five years. “Appliance manufacturers are looking to expand this market, but they are also looking for alternatives, since stainless steel is expensive,” noted David Christopher, strategic account manager. “Stainless steel appliances are an attractive business for both the manufacturer and retailer. The affluent consumer that is looking for stainless steel is probably going to buy it, but there is a segment of the market that likes the look of stainless steel but simply cannot afford it. This is where the brushed zinc-nickel product offers an alternative.

“The brushed zinc-nickel product will allow the retailer and manufacturer to create a market shift up and provide differentiation in the market. It will likely cost more than painted appliances, but less than stainless steel,” said Mr. Christopher.

“There are other advantages,” added Mr. Hughes. “Our product provides a metallic substrate which magnets can adhere to. That may not sound exciting, but for many families, that is important. Also, the coating resists fingerprints. There are other markets we are looking at as well, such as the automotive interior trim and telecommunications.”

Brushed zinc-nickel is a mechanical process that levels out the crystalline structure of electrogalvanized finishes. This changes the light reflectance, giving the coil a highly polished, reflective look. The proprietary roll-type sanding system is part of the coil coating line. This, as with the other finishes offered by Walbridge, allows the entire process to be completed in one cycle.

Another unique process of the Walbridge line is that it has metal-to-metal lamination capability. Various SoundTrapTM and Quiet Steel® products can be produced for the automotive, HVAC and appliance markets to help reduce noise and vibration. The product is made of two skins of metal with a viscoelastic polymer core that dampens noise and vibration at various temperatures. Different polymers are used depending on the application temperature in which noise is generated. The Quiet Steel® product is currently being used today in applications such as dash panels, oil pans and brake dampers. There is a growing need for these types of products in the appliance market in dishwasher, washer and dryer applications. “Noise performance is a very important feature for consumers when purchasing appliance products,” noted Mr. Christopher.

“We are trying to educate clients that they do not have to pull coils off the line and send them somewhere else for more processing. It can all be accomplished in one pass, saving them money. Plus, they get a superior product in terms of corrosion performance and formability as well as one that is correctly engineered,” concluded Mr. Hughes.