IHEA Announces Industrial Heating Decarbonization Summit

Edited by Hannah Zelinski

The Industrial Heating Equipment Association (IHEA) will be holding the Industrial Heating Decarbonization Summit in October.

AkzoNobel Ups Powder Coatings Capacity With Investments

Edited by Hannah Zelinski

AkzoNobel has invested $30 million into its North American power coatings manufacturing sites in order to expand its reach and capabilities.

PPG Unveils Copper-Free Antifouling Coating

Edited by Hannah Zelinski

Nexeon 810 surface technology delivers emissions savings.

Deadline March 31 for 2024 Parts Cleaning Conference Speaker Submissions

By: Lori Beckman

Do you have an interest in speaking at the Parts Cleaning Conference in September at IMTS? Submit your abstract now!

BIM Files for Lorin’s Finishes Available for Direct Download

Edited by Hannah Zelinski

Access BIM files for anodized aluminum colors and finishes on Lorin’s website.

AkzoNobel Achieves 100% Renewable Electricity in Latin America

AkzoNobel has announced that all of its Latin America-based manufacturing facilities are now operating on 100% renewable electricity.

#sustainability

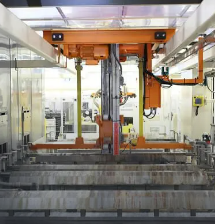

Innovance Inc. Acquires Jorgensen Conveyor and Filtration Solutions

Edited by Scott Francis

Innovance has announced the acquisition of Jorgensen Conveyor and Filtration Solutions.

Water Filtration System Reduces Variety of Contaminants

Edited by Lori Beckman

The system offers compliant water discharge and recycling of significant amounts of water.

PPG supports AMPP's EMERG Programs for future innovators

Edited by Scott Francis

PPG contribution will support several AMPP programs designed to foster education and innovation in coatings and corrosion.

#workforce development #education

Uyemura Boosts Field and Met Lab Teams

Edited by Lori Beckman

Russ Schwartz, a senior mechanical engineer, and Steve Medd, support engineer, add expertise to the team at Uyemura.

Used Plating Equipment Website Goes Live

Edited by Lori Beckman

Ronatec is launching a used finishing equipment website designed to offer a secure experience for both sellers and buyers.

Sherwin-Williams releases printed metal coil coatings collection

Edited by Scott Francis

New Sherwin-Williams coil coatings collection aims to bring an enhanced look of natural building materials for architectural applications.