Sherwin-Williams releases printed metal coil coatings collection

Edited by Scott Francis

New Sherwin-Williams coil coatings collection aims to bring an enhanced look of natural building materials for architectural applications.

Spray Tech Industrial Solutions Merges with PBS Industries

Edited by Scott Francis

The merger combines expertise in cutting-edge spray coating technologies with that in industrial ventilation equipment solutions.

Company Builds $7 Million Laboratory

Edited by Lori Beckman

The 11,000-square-foot facility will provide the space required to advance product development and pilot new formulations within the company’s core markets.

President of Sames North America Assumes Role as President, Sames Americas

Edited by Lori Beckman

In this expanded role, Regan Murray will maintain the oversight of the company’s North American operations, spanning the USA, Canada and Mexico, while also spearheading the management of the teams in Brazil and Argentina.

Regulatory Changes Drive Cleaning Companies' Collaboration

Edited by Lori Beckman

Hubbard-Hall and Jayco Cleaning Technologies have collaborated to develop a solution for new regulatory changes.

Bill Rickenbaugh Joins Carlisle as Account Manager

Edited by Lori Beckman

Rickenbaugh has over 30 years of finishing experience, most recently as senior finish improvement specialist for Masterbrand Cabinets.

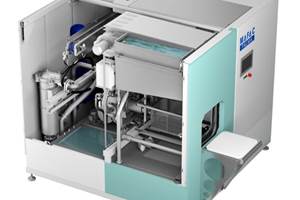

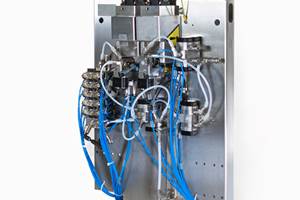

Dürr Expands its Color Dosing and Changing System

Edited by Lori Beckman

By offering the Fluid Board, the company is expanding its ready2integrate package, enabling customers to quickly and easily assemble a high-quality solution comprising a controller, dosing technology and applicator.

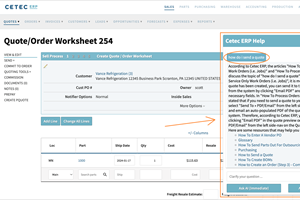

Cetec ERP Launches AI Chatbot

Edited by Lori Beckman

The tool has been developed to provide an option for customers to get immediate responses to the most common questions.

Walter Surface Technologies Hires Safety Sales Director

Edited by Lori Beckman

In this role, Jean-Marie Maayoufi will lead Allegro’s safety specialists in North America toward growth.

Paul N. Gardner Jr, 81, Dies

Edited by Lori Beckman

Former president and chairman of the board of the Paul N. Gardner Co. (Gardco), died on Feb. 8, 2024. His legacy is one of dedication, passion and an unwavering commitment to excellence.

PCI 2024 Board of Directors and Executive Officers

Edited by Lori Beckman

PCI is grateful for these individuals who share their valuable time setting goals and making sure the institute stays on task.

16-LED Ring Illuminator Streamlines Industrial Microscopy

Edited by Lori Beckman

This 360-degree shadow-free light provides consistent illumination while eliminating obstructive shadows, making it especially useful for detailed examinations and precision work.

#measurement-testing