A Consequence of Electrification

Although there is a whole lot of talk nowadays in the auto industry about materials including aluminum, ultra-high-strength steel, and composites, there is another material that, Jeff Owens, chief technology officer and executive vice president, Delphi Automotive, told the audience this week at the CAR Group Management Briefing Seminars that is going to have huge growth in automotive: Copper.

Although there is a whole lot of talk nowadays in the auto industry about materials including aluminum, ultra-high-strength steel, and composites, there is another material that, Jeff Owens, chief technology officer and executive vice president, Delphi Automotive, told the audience this week at the CAR Group Management Briefing Seminars that is going to have huge growth in automotive:

Copper.

Featured Content

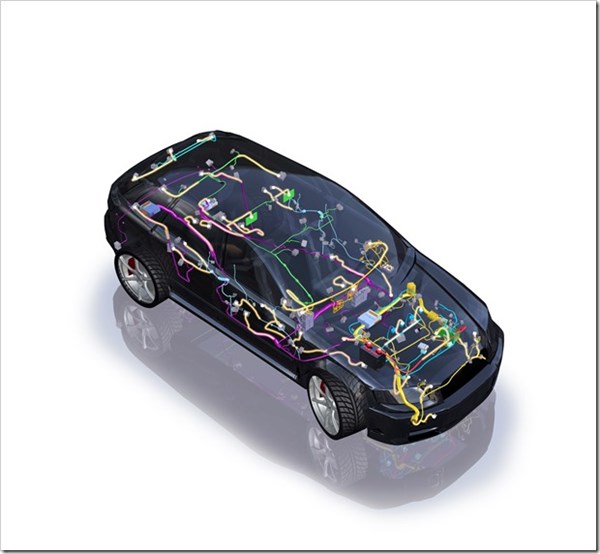

Speaking to the issue of increased networking and electrification in vehicles, he said that whereas there is currently about 7.5 kg of copper in the average car, that’s going to go to 15 kg.

What’s more, there is going to be an increase in wiring and cabling from 1 mile to 1.5 miles. There will be a need for vehicular voltage to go from 12 volts to 300 to 600 volts. What was once a $2 connector may become a $20 connector.

Just providing the support for an electrified powertrain will mean an additional cost from $500 to $800 per vehicle.

Speaking of cost: Owens says that he is doubtful that there will be fully autonomous cars not only because of the regulatory, legal and technical challenges (sensors, computing platforms, control systems, etc. etc. etc.), but: “Will the consumer pay for it?”

RELATED CONTENT

-

Finishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

-

Enhanced Functionality, Commercial Viability

Nano-particle additives modify coating performance to protect sensitive electronic devices.

-

RoHS and ELV Compliant Electroless Nickel

Over the past few years, a number of new environmental directives have come out of Europe and Asia encompassing mainly the automotive and electronics industries.

.jpg;width=70;height=70;mode=crop)