NDSU researchers develop coatings from crops

Several agricultural crops could play a significant role in biobased resins and coatings recently developed by researchers at North Dakota State University. Scientists at NDSU have developed biobased resins that may prove to be a “game changer” in coatings and resin technology. The NDSU researchers have developed a family of resins from renewable raw materials, creating resins that eliminate hazardous components such as formaldehyde and bisphenol-A. The resins are based on sucrose and vegetable oils, and can be varied to perform in many applications and industries.

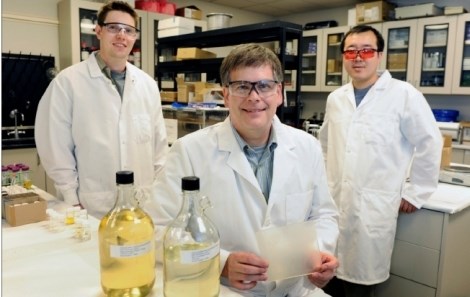

Dr. Dean Webster, North Dakota State University, Fargo, (center) and graduate students T.J. Nelson and Xiao Pan are among a research group that developed a family of resins from renewable raw materials. Photo credit: Dan Koeck, NDSU

Featured Content

Several agricultural crops could play a significant role in biobased resins and coatings recently developed by researchers at North Dakota State University. Scientists at NDSU have developed biobased resins that may prove to be a “game changer” in coatings and resin technology.

The NDSU researchers have developed a family of resins from renewable raw materials, creating resins that eliminate hazardous components such as formaldehyde and bisphenol-A. The resins are based on sucrose and vegetable oils, and can be varied to perform in many applications and industries, according to Dean Webster, professor in the NDSU Department of Coatings and Polymeric Materials. Webster’s research group includes NDSU graduate students Xiao Pan and T. J. Nelson, undergraduate student Adlina Paramarta and Partha Sengupta, former postdoctoral researcher at NDSU.

The resins developed by the NDSU research group can be made from from sugarbeets, plus oils from soybeans, flax and sunflowers. When cured, the patent-pending resins show:

-Significantly improved properties over current biobased materials and processes

-Mechanical properties comparable to petrochemical-based materials

-Dramatically increased renewable material content

“These NDSU-developed technologies achieve what few biobased materials have before,” said Webster. “They have vastly improved mechanical properties, reduced hazardous chemical content and are made from readily available materials and common processes. The technologies have the potential for significantly impacting biobased material markets.” The biorenewable chemicals market is projected to reach $5 billion by 2015.

RELATED CONTENT

-

Understanding Infrared Curing

Infrared cure is gaining increased attention from coaters as a result of shorter cure cycles and the possibility of smaller floor space requirements when compared to convection oven curing.

-

Touch-up Options for Powder Coated Parts

Is it true that powder coating cannot be touched up? Powder coating expert Rodger Talbert offers options for powder coating touch-ups.

-

Improving Transfer Efficiencies in Coating Operations

There are many methods for addressing electrostatic grounding in metal painting processes, and Tim Ulshafer from Mueller Electric says the best method for your process is a simple and worthwhile exercise.