NY/NJ's Masters Association of Metal Finishers Honors Members

Honorees included Walter Schwartz, who received the Award of Special Recognition for his work in the industry, and New Brunswick Plating, which received the Stephen Candiloro Memorial Award.

NASF Palmetto Southeast Chapter Plating Course a Success

The five-hour technical presentation attracted about 50 industry professionals from throughout the southeast region.

#nasf

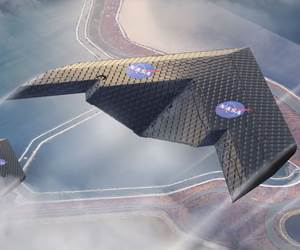

MIT and NASA Engineers Design New Airplane Wing with Movable Surfaces

Researchers say the new wing could provide a significant boost in aircraft production, flight and maintenance efficiency.

#aerospace

Bales Metal Surface Solutions Enhances In-house Lab Capabilities

Bales upgraded the lab equipment to allow for automated titration of the plating baths and acquired two atomic absorption spectroscopy (AAS) machines.

Protech Metal Finishing Completes Expansion of New Facility

Additions brings about 32,000 square feet of production space and an increased number of production lines.

Pioneer Metal Finishing Soars on Employees, Culture

Pioneer uses their own Pioneer TV Network, company newsletter, fundamentals activities and training to get new and current employees integrated into the company culture and expectations.

#management #workforcedevelopment

Continuous Improvements Drive Elite Metal Finishing

Elite Metal Finishing was singled out for Best Practices in the Products Finishing Top Shops Benchmarking Survey because of their extremely high detail to quality and customer communication.

#topshops

Armoloy's New Owners Use Simple Marketing Strategy to Build Electroplating Business

Nolan Hannan and Jacob Meier purchased Armoloy in 2017, and knew they wanted a data-driven shop that they provided information on how well the shop was operating, and where improvements could be made.

#topshops #management

How to Use Manufacturing Technology to Reach Finishing Goals

If your coating operation has big growth goals for this year, then solutions engineer Bill McGee from Plex Systems says you should have a deep understanding of the way your shop works.

#basics