Cleaning Q&A: Citric Acid Passivation

Enlighten me on the use of citric acid in the passivation of our steel products.

Cleaning Q&A: Maintenace of Process Chemicals

What is an accurate, fast and cost-effective means to monitor an aqueous pre-cleaning solution and passivation fluid titration/pH measuring?

Cleaning Q&A: Increasing Speed of Stripping Wheels

Can you recommend a stripping method that will help me increase the speed of removal?

Simply Water for Parts Cleaning

When it comes to critical cleaning, plan the way you use water.

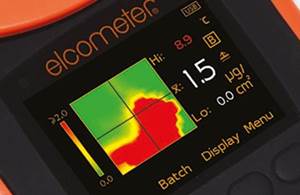

Measure soluble salts on surfaces significantly faster with the new Elcometer 130 SSP Soluble Salt Profiler

Portable, hand-held gauge which accurately and reliably measures 4 Bresle equivalent readings in less than three minutes

#curing #masking #measurement-testing

BASF Presents Winner of 2016 Fight Club of Automotive Design

Omar Gonzalez won the 2016 Middlecott Sketchbattle Experiment, Detroit’s first-ever “Fight Club of Design."

#masking #pollutioncontrol #curing

Akzo Nobel to buy BASF coatings

The transaction would include technologies, patents and trademarks, as well as securing supply to customers worldwide.

#masking #pollutioncontrol #curing

Crown Group earns John Deere Supplier of the Year and Partner-level Supplier

Crown Group is a supplier of coating services to John Deere’s Tractor Cab and Assembly Operations in Waterloo, Iowa.

#construction #masking #pollutioncontrol

Steel Manufacturer Hannibal Ind. Opens Houston Plant, Powder Coat Facility

110,000-square-foot facility will house the company's new powder-coating production line, an environmental room and additional office space.

#curing #masking #sustainability

Painting a Boeing 737: See The Video

The cost is between $100,000 to $200,000 to prep and paint each plane, depending on which colors are chosen, and how many colors.

#masking #aerospace #pollutioncontrol