Engineered Shaped Grain Abrasives Take Grinding Productivity to New Heights

Unique three-pointed curved grain approach offers advantages for tough grinding applications.

Robot-Ready Grinding Systems for High-Speed Production

Advanced rotary surface grinders now come “robot-ready” to facilitate integration with third party robotic arms and fully automate the process from loading to unloading.

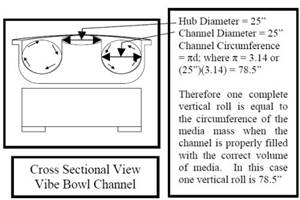

Calculating Applied Media Force During Vibratory Finishing

What appear to be identically set-up vibratory bowls will finish identical loads of parts in varying time cycles. This paper offers a new technique to better predict what the operator will produce, by measuring the force applied to the parts. It is the efficiency of that force which controls the efficiency and speed of the refinement cycle.

#surfin #research

Best Practices for Blast Room Maintenance

A high-quality blast room is a large investment. Brandon Acker of Titan Abrasive Systems discusses proper care for your blasting equipment.

#asktheexpert

Blasting Beads Made of Lead-Free Natron Glass

SwarcoBlast blasting media are made for use in a multitude of surface refinement applications.

Lapping, Polishing Film Maximizes Strengths, Maintains Flexibility

Dia-Strip and Dia-Sheet film from Titan Tool Supply has a distinct construction that the company says makes it durable while remaining flexible, bendable and formable.

Blast Nozzle Features Enhanced Noise Reduction

Kennametal adds noise-reducing Blast Ninja to portfolio of abrasive blast nozzles.

Hubbard-Hall Technical Team Adds Senior Chemist to Staff

David Keller is joining the Hubbard-Hall technical team as a senior chemist.

Wall Colmonoy Hires Business Development Manager, Surfacing Products

Wall Colmonoy welcomes Josh Gardner as its business development manager of surfacing products.

#management

Miles Chemical Anaheim Doubles Capacity with Second Building

Miles Chemical Anaheim is doubling its capacity with the purchase of a second facility adjacent to its existing one.

#workforcedevelopment