Each year, a long list of names are submitted to Products Finishing’s 40 Under 40 program, which recognizes the hard work, motivation and passion of individuals that drive the surface finishing industry forward. Recipients are chosen based on a variety of curriculum, including leadership and industry involvement.

Read the bios below to learn more about 40 under 40’s class of 2023. Each finalist was asked why they love the finishing industry to which they responded with their own unique answers. Whether on the shop floor or working on the business side of a company, every nominee is involved in the surface finishing industry, contributing in different ways to the industry’s future.

Featured Content

Meet the 40 Under 40 Class of 2023

“I am all about the next generation involved in the surface finishing industry.” – Brandon Anthony

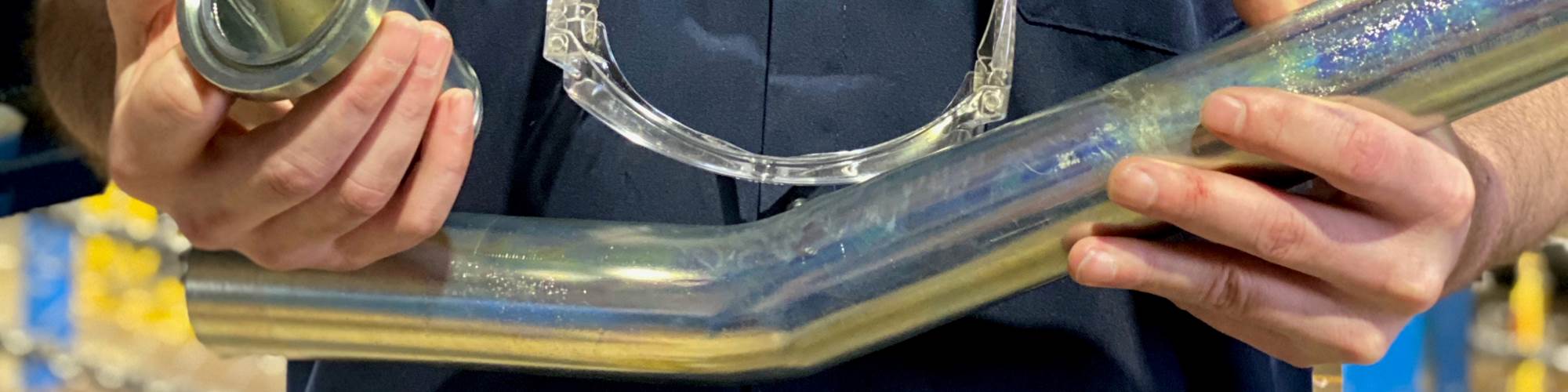

Photo Credit: Precision Metal Processing

Brandon Anthony

President | Precision Metal Processing

Brandon Anthony began his career in the metal finishing industry at 15 years old, working at multiple companies learning the industry. After five years, he began his own business: Precision Metal Processing. Seven years later at the end of 2020, Anthony incorporated and opened up his own anodizing shop.

“I have loved being involved in the Finishing Industry as an Application Engineer and then a Product Line Specialist for Nordson Corporation since 2014. Working at a company that emphasizes customer success through product innovation and strategic discipline has afforded me many unique and exciting problem solving opportunities. This is all the more rewarding in the finishing industry because I have the opportunity to enjoy these successes in the quality products I buy for my home.” – Gus Bailey

Photo Credit: Nordson

Gus Bailey

Global Product Line Specialist, Powder | Nordson Corp.

Gus Bailey is a dynamic young leader with over nine years of experience in Nordson’s powder group with Industrial Coating Systems. Bailey worked for eight years as an application engineer managing powder projects and was integral in the design and management of countless high-profile projects before being promoted to global product line specialist for powder.

“What I love about the industry are the challenges presented in the field on a daily basis and the opportunity to assist the customer in running consistent, quality metal.” – Ryan Braunschneider

Photo Credit: Haviland Products Co.

Ryan Braunschneider

Technical Sales Representative | Haviland Products Co.

Ryan Braunschneider has developed from an inside salesperson with no chemical experience to one of the anodizing industry's go-to technical experts. He consistently receives praise from customers and colleagues regarding his knowledge and dedication. Braunschneider is eager to learn new technology so that he can understand and service any needs that customers may have. He does not limit himself to only an understanding of the chemistry Haviland sells, but the whole process being used by the customer.

“Throughout my career, I have had the fortune to meet a variety of people across the finishing industry. What I enjoy most is their willingness to share their knowledge and accept new talent into the field.” – Will Burke

Photo Credit: Parker Ionics

Will Burke

Project Engineer | Parker Ionics

Will Burke started at Parker Ionics as an intern while studying engineering at the University of Michigan. Whether at a CAD computer or in the shop working hands-on, Burke contributed to the advancement of designs and custom build to order business. After graduation, Burke returned to Parker Ionics, taking on a leadership role in the engineering department. He is now responsible for 75% of the projects that come through the shop.

“I enjoy the day-to-day challenges being a supervisor brings, collaborating with my team to get jobs out the door and back to the customers in a timely manner while still maintaining the quality of work completed. Also, working with other departments to learn new techniques that will help improve efficiency throughout the shop.” – Elizabeth Eckroad

Photo Credit: Avtec Finishing Systems

Elizabeth Eckroad

Production Supervisor | Avtec Finishing Systems

Elizabeth Eckroad was promoted to production supervisor after working as a line operator for seven years at Avtec Finishing Systems. The company says she has been a great help in organizing training for future line operators and racking/unpacking employees. She has great skill in finding out what motivates a workforce and playing to those strengths.

“What I love about working in the metal finishing industry is the satisfaction I get when I’ve taken a customer’s piece of equipment from an unusable, broken state and repaired it back to working condition. The customers are always so grateful when their units are repaired and they can return back to full production. Many times, I see people’s complete demeanor change when I deliver the good news. It’s what drives me forward. To see that change on a customer’s face is the best reward there is.” – Matthew Gordon

Photo Credit: Dynapower

Matthew Gordon

Field Services Engineer | Dynapower

With his quick thinking, flexible approach and intuition, Matthew Gordon has toiled countless hours in metal finishing shops restoring critical plating equipment. Gordon interviewed with Dynapower not knowing much about the metal finishing industry, but he was determined to become the best. A memorable line from his interview was, "I may not be your best technician now, but I promise you: I will be."

“What I love about the surface finishing industry is the pride that each shop carries in their company, people, culture, processes, customers, quality, turnaround times and the finished product!” – Jeff Halonen

Photo Credit: Steelhead Technologies

Jeff Halonen

CEO, Co-Founder | Steelhead Technologies

Jeff Halonen and the other co-founders of Steelhead Technologies started building the plant operations technology in 2020 when they heard many finishing shops were experiencing similar problems — clunky workflows, manual communication, limited insight into business and operations, and more. Today, Halonen continues to serve the products finishing industry with enthusiasm, commitment to excellence and a dedication to exceeding customer expectations.

“Refinements in surface finishing and the capabilities made possible by such are what will drive the global electric future. Progress is the fuel that drives us towards success. By setting our sights on what we want to achieve and making steady progress towards our goals, we can create a future that exceeds our wildest dreams.” – Justin Koch

Photo Credit: Advanced Plating Technologies

Justin Koch

Manufacturing and Process Engineer | Advanced Plating Technologies

Justin Koch has been a stellar addition to the Advanced Plating Technologies team and has acquired the skills of the craft at an accelerated pace, the company says. He is a model of engineer the company needs for the next generation, both an asset to APT and the industry. Koch directly oversees work that requires higher levels of oversight and attention, fully embracing APT’s credo of “boots on the ground” by being on the production floor every day getting his hands dirty.

“I love surface finishing technologies because of their amazing effectiveness in enhancing the substrates’ performance, their important and wide applications and all the challenges for continual improvement.”

– Jenny Ma

Photo Credit: Pavco Inc.

Juan “Jenny” Ma

R&D Chemist | Pavco Inc.

Jenny Ma’s focus within research at Pavco is continuing to strengthen the company’s comprehensive understanding of how various layers of coatings correlate to torque-tension. On top of her research acumen, Ma also successfully assumed the managerial role of Pavco’s quality program for ongoing ISO 9001:2015 compliance and certification. Ma’s academic foundation combined with a strong work ethic and organizational skills continue to result in a significant positive impact for Pavco and the metal finishing industry.

“I appreciate the entrepreneurial spirit and dedication of finishers. At every shop that I’ve visited, finishers are going the extra mile, above and beyond, to deliver quality products.” – Connor McAnespie

Photo Credit: Hanna Instruments

Conor McAnespie

Northeast Regional Sales Manager | Hanna Instruments

Throughout his tenure at Hanna Instruments, Conor McAnespie has shown tremendous growth in his career and distinguished himself as a thought leader in the finishing industry space. McAnespie has demonstrated leadership qualities both at Hanna and in the metal finishing industry community, including in his involvement as a member in multiple regional surface finishing associations and a participant in several speaking engagements. He has also led panel discussions on webinars hosted by Products Finishing.

“As the general manager of Apex Anodizing, I love the challenge of balancing technical expertise, team leadership and customer satisfaction to deliver high-quality results and build lasting relationships in northern Nevada.” – Drew Nunez

Photo Credit: Apex Anodizing

Drew Nunez

General Manager | Apex Anodizing Inc.

Under Drew Nunez’s leadership, Apex Anodizing in Sparks, Nevada, grew from a 5,000-square-foot anodizing shop to a 20,000-square-foot facility. Originally from Apex’s Portland, Oregon, location, he answered the call to move to Nevada to help build and sustain the new venture in 2005. Nunez’s drive made Apex one of the largest private finishers in Nevada, adding zinc and nickel plating lines as well as powder coating and a blasting department.

“Moving into the plating industry from machining really helped me understand the amount of work metal finishers have to do to make a part look so good.” – Cesar Olivas

Photo Credit: Controlled Plating Technologies

Cesar Olivas

Production Manager | Controlled Plating Technologies

Cesar Olivas brought his technical skill set from a prior career in machining to Controlled Plating Technologies’ production and quoting. His focus on efficiency has helped improve many different facets of business, including the company’s first-pass quality yield, turn-around times, reduction of labor costs, order completion estimates, customer communication and more. After suggesting and implementing changes across the floor layout and workflow, he quickly climbed the ranks at CPT and now manages all production at the company.

“Being able to assist suppliers in providing exceptional products to their customers is an outstanding reward. I am honored that I can contribute to these processes.”

– James Perigen

Photo Credit: Kyzen

James Perigen

Senior Quality Control Chemist | Kyzen

Jamie Perigen is senior quality control chemist with Kyzen.

“What I love about the finishing industry is that every day is different and filled with new challenges. Surround yourself with good people and you can succeed.” – Mike Pypiak

Photo Credit: Associated Finishing Inc.

Mike Pypiak

Key Account Manager | Circle-Prosco Inc.

Mike Pypiak has become a leader in the metal finishing industry through his dedication to his customers’ success and service to leading trade organizations. He was named president of the Chemical Coaters Association International – Carolinas Chapter. Mike’s customers rely on his ability to troubleshoot pretreatment challenges while finding opportunities for process improvements and cost savings. Pypiak has done everything from participating in system cleanouts to leading webinars in partnership with Products Finshing, all while furthering the development of his client base.

“Chemical manufacturing plays a critical role in driving progress and advancing technology in fields ranging from medicine and electronics to construction and transportation. It is a constantly evolving industry, with new materials, processes, and applications emerging all the time. For those who are dedicated to the responsible and sustainable use of chemicals, there is a real sense of purpose in contributing to the advancement of society and the betterment of the world.” – Ram Sarathy

Photo Credit: Palm Commodities International

Ram Sarathy

Plant Operations Manager | Palm Commodities International

Ram Sarathy has been instrumental in directing several manufacturing and facility improvements that have allowed Palm Commodities International to expand its product portfolio. His knowledge of chemistry and manufacturing processes has been a critical component needed to enable the company to achieve its growth targets.

“I personally devote the majority of my time to creating robust processing systems with a focus on high-volume programs that require cosmetic finishes. Nine times out of ten we are the last team to handle a part. My goal is to always give our customers the confidence and support they need in that very critical part of their supply chain.” — John Serritella Jr.

Photo Credit: Chicago Anodizing Co.

John Serritella Jr.

Vice President of Operations | Chicago Anodizing Co.

John Serritella Jr. was extremely instrumental with putting in procedures and processes to take Chicago Anodizing Co. to new heights. During the pandemic, Serritella worked with all team members to ensure safety and made sure a full line of communication was established with customers to meet orders, especially those in the medical industry. His other accomplishments include assisting with the company’s facility expansion and the implementation of inventory systems and quality systems for better customer assistance.

“My love for the finishing industry is driven by the constant development of technology. As liquid technology changes so does the equipment. Interacting with our customers is what I look forward to every day.” – Neil Sherfey

Photo Credit: Total Finishing Solutions

Neil Sherfey

Change Agent | Total Finishing Solutions

Neil Sherfey has a vast knowledge of the finishing industry and works with all customers with an intense passion regardless of their size. The company says his dedication and thirst for knowledge is second to none, and he continually uses this drive to seek new and better solutions for his customers, demonstrating his ardor and dedication to personal and professional growth.

Photo Credit: Dipsol of America

Shuntaro Tsukiyama

Technical Director | Dipsol of America Inc.

Shuntaro Tsukiyama has been in the surface finishing industry for over 13 years where he has performed a variety of different roles. Tsukiyama helped start and develop the Dipsol Europe branch and spearheaded the research and development team at Dipsol of America. Additionally, Tsukiyama has headed the installation and upgrades of new equipment in the lab at Dipsol of America. The company says one of the greatest things about Tsukiyama is that he does not need a reason to stop and help anyone — he just does.

“I love the plating industry because I enjoy the challenge of improving important processes. From consumer goods to medical supplies, plating is everywhere and driving the industry forward is rewarding.” – Toby Varland

Photo Credit: Varland Plating

Toby Varland

Vice President of Technology | Varland Plating

Toby Varland cites his history with Varland Plating and experience working his way up from the plant floor for his success on managing the company’s technology. Understanding and participating in plant floor operations has allowed him to tackle problems with creative solutions, providing business value. Varland’s ability to serve as a jack of all trades allows him to operate with a holistic perspective of the company’s needs and has led to him being known as an expert both within and beyond Varland Plating.

“My favorite thing about working in the metal finishing industry is that every day is an opportunity to troubleshoot a new problem and expand my knowledge.” – Milica Zivak

Photo Credit: Columbia Chemical

Milica Zivak

Lab Chemist | Columbia Chemical

Milica Zivak is well known for her analytical mind and commitment to enhancing process efficiency, driven by a goal to apply analytical thinking and instrumentation to additional aspects of the company’s operations and to make an intellectual impact on Columbia Chemical and the industry as a whole. A major accomplishment of hers was achieving a nearly 75% reduction in the analysis time of a semi-bright carrier by adjusting time, flow rates and mobile phases.

RELATED CONTENT

-

Videos: 40 Under 40 Class of 2024

In these uncertain times, it is refreshing to hear from and learn about young talent in the surface finishing industry who are striving to make a difference within their organizations and the industry as a whole.

-

40 Under 40: Class of 2022

Products Finishing announces this year’s 40-Under-40 award recipients. The annual program recognizes emerging leaders working to forward the surface finishing industry.

-

Electrodeposited Nickel Composites Containing Diamond Particles

Originally published as J. Zahavi and J. Hazan, Plating and Surface Finishing, 70 (2), 57-61 (1983), this paper was awarded the 1984 AESF Gold Medal for Best Paper published in Plating and Surface Finishing in 1983. The work, methodology and results discussed here remain valuable from a historical standpoint.