Additive Manufacturing and Surface Finishing - The 53rd William Blum Lecture

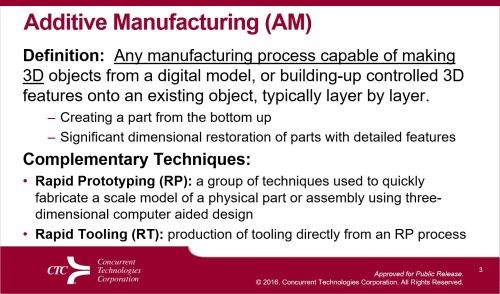

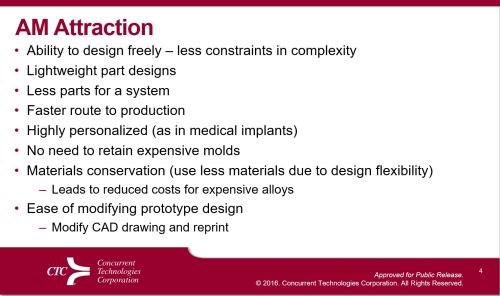

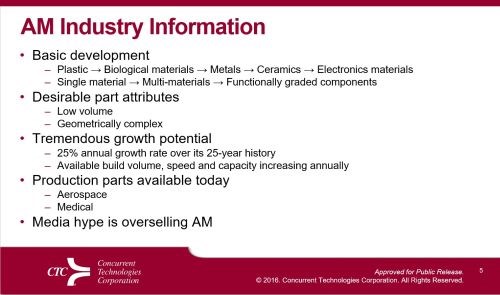

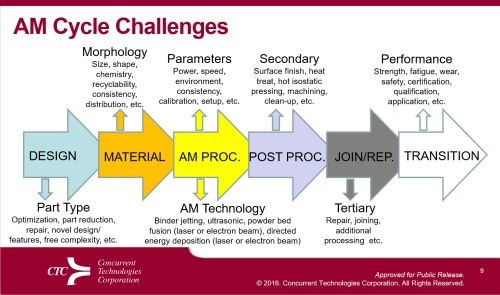

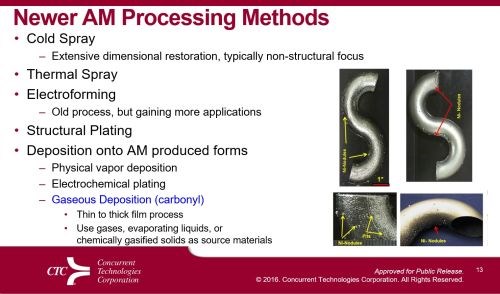

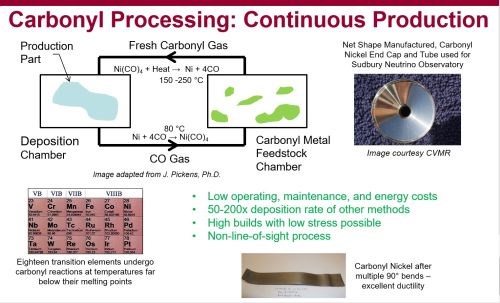

This presentation is the 53rd William Blum Lecture, presented at SUR/FIN 2016 in Las Vegas, Nevada on June 6, 2016. In this lecture, Dr. Melissa Klingenberg discusses additive manufacturing; that is, any manufacturing process capable of making 3D objects from a digital model, or building-up 3D features onto an existing object, layer-by-layer. Cold spray, thermal spray, electroforming, structural plating and gaseous carbonyl deposition are covered.

#research #additive-manufacturing #surfin

by

Dr. Melissa Klingenberg

Featured Content

Recipient of the 2015 William Blum

NASF Scientific Achievement Award

Editor’s Note: The following is the Powerpoint presentation by Dr. Klingenberg in delivering her William Blum Memorial Lecture at SUR/FIN 2016, in Las Vegas, Nevada on June 6, 2016. A printable version of the presentation is available by clicking HERE.

About the author

Editor’s Note: The following was published by Concurrent Technologies Corporation, Johnstown, Pennsylvania, and the interview was published in Products Finishing at the time the Dr. Klingenberg was announced as the winner of the 2015 NASF William Blum Scientific Achievement Award at SUR/FIN 2015 in Rosemont, Illinois.

Melissa Klingenberg, Ph.D., a Principal Advisor Engineer at Concurrent Technologies Corporation (CTC), has been awarded the 2015 National Association for Surface Finishing's (NASF) Scientific Achievement Award. She is the first woman to win the top honor in the 57-year history of the Scientific Achievement Award. The NASF presents the award annually to "an individual who greatly contributes to the advancement of the theory and practice of electroplating, metal finishing and the allied arts; raises the quality of processes and products; and has enhanced the dignity and status of the profession."

"It's the greatest honor of my career," Klingenberg said. "I've always thought it was the most prestigious award for science within the metal finishing industry, and I am very excited and honored to have won. I always thought this honor was beyond my reach and have admired the men who won it in the past."

Rob Mason, CTC's Principal Materials and Process Scientist and NACE Certified Corrosion Technologist, noted, "The Scientific Achievement Award is very prestigious, and Dr. Klingenberg really deserves it. She is probably the first and foremost thought leader in the industry with respect to metal finishing wear-resistant coatings. She is a working scientist, clients love her, and she is respected as the go-to authority by many people across the country. I can't emphasize enough that she is incredibly worthy of this industry-leading award." Mason nominated Dr. Klingenberg for the honor, which was voted upon by an NASF committee.

Products Finishing Editor Tim Pennington writes, "Dr. Klingenberg has done it all for the industry: serving as AESF Foundation president, serving on the AESF Council, the NASF Research Board, the Emerging Technologies Committee, the Sur/Fin Technical Committee and as organizer and conference chair for the Surface Engineering for Defense and Aerospace Applications Conference.

"She has been an active member of NASF since 1994, and in 2008 organized and co-chaired the first ASM International/NASF Surface Engineering for Defense and Aerospace Applications conference. Her award has been especially deserving because it has been through those activities with the NASF that many feel that Dr. Klingenberg was critical in 'reinventing' the NASF to attract additional experts to conferences in the areas of innovative coating and new surface finishing technologies."

Klingenberg has more than 20 years of experience in inorganic finishing operations, specializing in research and development, technology evaluation, and implementation of innovative coatings and surface finishing processes designed to improve engineering properties and address environmental issues. She identifies, designs, integrates/installs, debugs, and implements systems including advanced deposition and plating processes, innovative coating and surface treatment technologies, and high energy and laser systems. Klingenberg is particularly known for her research in wear-resistant coatings and cadmium and chromium replacement technologies for defense applications, and she has co-authored numerous papers, articles, and presentations on these subjects. Her efforts have involved coatings deposited by physical vapor deposition (PVD) and brush plating, as well as advanced technologies and concepts, such as the use of ionic liquids for cleaning and plating.

In addition to her career as a scientist, Klingenberg is married to Scott Klingenberg, and they have one daughter, Gabrielle. They live in Windber, PA.

Klingenberg received a bachelor's of science degree in chemistry and engaged in post-baccalaureate studies in biology at the University of Pittsburgh at Johnstown. She received a master's degree in manufacturing systems engineering at the University of Pittsburgh and a Ph.D. in materials engineering at the Pennsylvania State University.

Melissa Klingenberg Ph.D., is a principal advisor engineer at Concurrent Technologies Corp., and the recipient of the 2015 NASF Scientific Achievement Award, the first woman to win the honor in the 57 years the award has been given.

PF: What does being the first woman to receive the 2015 NASF Scientific Achievement Award mean for the industry?

MK: I think that the award is something that anyone in the industry, regardless of gender, is inspired by to help innovate and broaden the industry. However, I think that having a woman honoree emphasizes that the industry supports and continues to provide excellent opportunities for women. It is my hope that this emphasis will help to continue to attract talented young women to support the industry.

PF: What does your role as principal advisor engineer entail?

MK: I collaborate with engineering, science and business staff to identify and deliver the best possible solutions for our clients. We leverage research, development, test and evaluation work to provide customized, transformative, full life-cycle solutions to support our clients’ core mission objectives. I also support technical and business strategic planning, generate and explore new research ideas, and mentor technical staff.

PF: What led you to the metal finishing industry?

MK: When I started at CTC, I had no preconceived notions as to what particular industry I’d be supporting. I was assigned as a junior engineer/scientist into the inorganic finishing area, and more specifically, advanced vacuum systems processing. I was fascinated by high energy surface modification and the physics and materials science behind the processes I was using. From there, I expanded into other dry processing methods as well as wet deposition, including electrodeposition, conversion coatings, etc. I really enjoyed modifying coating compositions, crystalline structures, and surface morphologies to manipulate properties, regardless of the process being used. This fascination drove me to continue my education to better understand how to engineer the properties of coatings.

PF: Tell us about your research in wear-resistant coatings.

MK: Our initial work focused on identifying and developing coatings that were capable of maintaining the engineering properties of coated parts when replacing cadmium or chromium, but doing so using a more environmentally acceptable process or material. However, as we searched for alternatives, we found that many processes, wet or dry methods, were capable of producing coatings that possessed superior properties through the introduction of high energy, alloying compositions or use of particle co-deposition. In some instances, we were incorporating ancillary equipment into conventional deposition means or using subsequent processing to produce better microstructures and even effect crystalline changes that inherently had better wear and corrosion properties. From there, we began narrowing our investigations to examining how different crystalline structures and morphologies of a single compositional range affected adhesive and abrasive wear properties and how we could slightly modify those properties to optimize the wear protection in a wear system pair.

PF: What is the secret to your success?

MK: Teamwork. I have been very fortunate throughout my career at CTC to work with so many talented technical, business, and support staff both inside and outside of our organization. I have learned something valuable from each and every individual with whom I have worked.

PF: What advice would you give to yourself 10 years ago?

MK: I would tell myself not to be overly stressed about things that are outside of my direct control.

PF: What was your first job and what did you learn from it?

MK: Part-time at the concession stand at our community pool. Although it has been quite some time since I worked there, I think that I learned that fast and friendly customer service is foremost in any business.

RELATED CONTENT

-

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications - 1st Quarterly Report

For 2022, NASF-AESF Foundation Research Board has selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. This report introduces the project and outlines the work to be undertaken.

-

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications – 2nd Quarterly Report

For 2022, NASF-AESF Foundation Research Board has selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. This report is the 2nd quarterly report, covering work during April-June 2022 and consists of an edited manuscript, “Manufacturing and Thermal Shock Characterization of Porous Yttria-Stabilized Zirconia for Hydrogen Energy Systems.”

-

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications - 6th Quarter Report

The NASF-AESF Foundation Research Board selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. In this period, work focused on 3D printing anode support for solid oxide fuel cells, SOFC (or cathode for solid oxide electrolyzers, SOEC) based on our designed optimization outlined in the previous report.