Alexandria Industries Celebrates 50th Anniversary with Acts of Kindness

In honor of its 50-year anniversary, employees are participating in 50 community service projects, taking the initiative to help people in their communities.

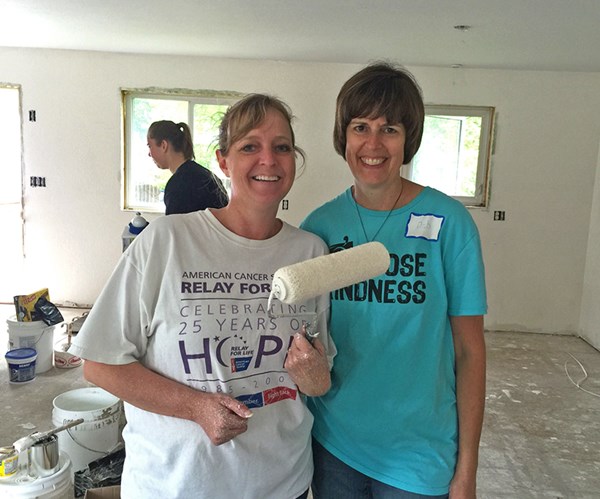

Marketing coordinator, Cindy Frederick (left) and Human Resources Manager Deb Moorman (right)

Alexandria Industries celebrates its 50th year in business as an aluminum extruder and provider of precision-engineered products. The company says it has found success over the years by serving a range of industries through decades of transformation and growth.

Featured Content

In honor of its 50-year anniversary, employees are participating in 50 community service projects, taking the initiative to help people in their communities. Projects include doing yard work, providing meals and spending time with elderly neighbors, fixing a college student’s garage door, and serving the youth ministry group at a local church. The random acts of kindness are meant to be simple, spontaneous and straight from the heart.

Starting in 1966, Alexandria Industries began supplying aluminum extrusions to companies such as IBM, Lennox and Honeywell. Today, the company continues to supply many leading companies in the medical device, electronics, solar, recreation and LED markets.

“I joined the company 29 years ago. With great fortune, we were able to build on a solid foundation created by excellent people who continue to serve our customers, communities and each other with their best,” CEO Tom Schabel says. “It is because of their efforts that we are able to create mutually successful and meaningful relationships, while staying true to our values throughout this journey we are on together.”

Alenxandria Industries produces customized aluminum extrusions and offers precision machining of ferrous and non-ferrous products, heatsinks, and plastic injection and foam molded components, as well as finishing and assembly services.

For more information, visit alexandriaindustries.com.

RELATED CONTENT

-

Zinc Electroplating

Choosing the best process for your operation.

-

Masking for Surface Finishing

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided. This article covers the many aspects of masking for metal finishing, including applications, methods and the various types of masking employed.

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.