Assessment of Safer Polysulfide and Polythioether Sealant Removers for Aerospace/Defense Industry Applications

This assessment identifies and evaluates potentially safer alternatives for sealant removal applications. The sealant removal performance of the alternatives was evaluated using a designed experiment.

#military #aerospace #research

Dr. Gregory Morose, Toxics Use Reduction Institute, University of Massachusetts Lowell

Dr. Jason Marshall, Toxics Use Reduction Institute, University of Massachusetts Lowell

Dayna Lamb, Raytheon Company

Chiagoziem Uzor, College of Health Sciences, University of Massachusetts Lowell

Featured Content

Abstract

Polysulfide and polythioether based sealants are widely used in the aerospace/defense industry to seal and protect components of aircraft, missiles, and other products. Maintenance, repair, and overhaul (MRO) operations require the removal of sealant from coated surfaces, mostly with the aid of sealant removal chemicals. In the aerospace/defense industry, commonly used sealant removers include hazardous chemicals such as toluene, methylene chloride, and N-propyl bromide.

This assessment identifies and evaluates potentially safer alternatives for sealant removal applications. The sealant removal performance of the alternatives was evaluated using a designed experiment. The environmental, health, and safety impacts of the alternative removal products were evaluated using the Pharos Chemical and Material Library chemical hazard assessment tool and the Toxics Use Reduction Institute’s Pollution Prevention Options Assessment System (P2OASys).

For the technical performance of the sealant removers, the PolyGone 310-AG product had the best results for all the sealant removers evaluated. The Diestone DLS, SkyKleen 1000, and Soy Safe Graffiti Remover products exhibited sealant removal performance comparable to that of toluene.

For environmental, health, and safety considerations, the SkyKleen 1000, PolyGone 310-AG, and Diestone DLS products had safer chemical profiles than toluene, nPB, and methylene chloride. The Soy Safe Graffiti Remover could not be fully evaluated because of limited information on the MSDS and the non-disclosure of the actual ingredients of the product.

Introduction

Polysulfide and polythioether sealants are widely used in the aerospace industry for sealing structures and components of aircrafts such as the windows, access doors, windshield, fuselage, fuel tanks, joints in the wings, and small rivets and bolts. Repair operations require efficient removal of the sealants from different surfaces. Chemical solvents are often utilized for their ability to be isolated to the area of the sealant, and increase the efficiency of the removal process. Hazardous chemicals such as toluene, methylene chloride, and N-propyl bromide are used for this purpose. However, while these chemicals meet the required performance objectives, they are hazardous to the environment and to the health of repair workers. This research was focused on identifying and evaluating potentially safer sealant removers.

The main goals of this evaluation were to accomplish the following:

- Identify potential safer alternatives for the removal of polysulfide and polythioether sealants in aircraft repair operations

- Screen out potential alternatives that do not meet the minimum performance and safety requirements

- Evaluate the chemical safety of the alternatives

- Evaluate the technical performance of the alternatives

Background

Sealant is primarily removed in the following two methods: 1) smaller parts are immersed in liquid sealant removal products for a pre-determined time, after which the sealant dissolves or is physically removed using a cutting or scraping instrument, 2) larger parts require an application of the sealant removal product directly onto the sealant area for a pre-determined time, after which the sealant either dissolves or is physically removed. This method typically requires the sealant removal product to be in a gel or paste state.

Some of the commonly used solvents for sealant removal are toluene, methylene chloride, and n-propyl bromide. These solvents are preferred because of their proven effective performance in weakening the strength of the sealants and therefore increasing the efficiency of the removal process over manual removal. There are significant human health hazards associated with exposure to such chemicals. The harmful health effects of these solvents are compounded by the potentially high occupational exposure potential for workers removing sealant. The workers are in close proximity to the solvents and therefore there is a high risk of inhalation exposure especially in poorly-ventilated areas, as well as dermal exposure potential.

In addition to the health effects, there is an increase in operation costs for companies who seek to protect workers from these hazardous solvents. Expenditures are often required for employee safety training, personal protective equipment, additional ventilation and other engineering controls, and the safe use and handling of hazardous materials and its subsequent disposal.

Research Methodology

Identification of Alternatives

The first step of this evaluation was to identify potential candidates to replace the use of the following hazardous sealant removal materials: toluene, methylene chloride, and N-propyl bromide. Potential safer alternatives were identified by utilizing the professional judgment of Toxics Use Reduction Institute (TURI) Cleaning Laboratory personnel, reviewing previous sealant removal test reports, using the TURI CleanerSolutions database, reviewing trade journals, and accessing manufacturer’s websites. The TURI CleanerSolutions database contains extensive information about the performance and safety of various industrial cleaners and solvents. (TURI, 2014a) As a result of this investigation, eighteen different sealant removal products were identified.

Aluminum Plates for Screening and Performance Testing

The performance screens and testing for this evaluation required the use of sealant strips applied to aluminum plates. There were two different aluminum plates used for this testing: 1) large aluminum plates and 2) small aluminum plates.

Large Aluminum Plates

TURI provided eighteen large aluminum plates made from 6061 and 7075 aluminum alloys with the following dimensions: 2” wide x 4.5” long x 0.25” thick. Each aluminum plate had four strips of sealant applied at the Raytheon facility in Tucson, Arizona. The sealant strips were applied to the top surface of the large aluminum plates and were approximately 0.5” wide by 2” long by 0.005” thick. The following six types of sealants were applied to the aluminum plates: 1) PPG Aerospace PR-1440, 2) 3M AC-735, 3) PPG Aerospace P/S 870, 4) PPG Aerospace PR- 1775, 5) Flame Master CS-5500, and 6) PPG Aerospace PR-2870. The large aluminum plates were used for the foam swab screen, the immersion screen, and the sealant removal performance testing.

Small Aluminum Plates

Raytheon provided eighteen small aluminum plates made from 2024 aluminum alloy with the following dimensions: 1” wide x 4” long x 0.075” thick. Each aluminum plate had three strips of sealant applied at the Raytheon facility in Tucson, Arizona. The sealant strips were applied to the top surface of the small aluminum plates and were approximately 1” wide by 1” long by 0.005” thick. The following six types of sealants were applied to the aluminum plates: 1) PPG Aerospace PR-1440, 2) 3M AC-735, 3) PPG Aerospace P/S 870, 4) PPG Aerospace PR- 1775, 5) Flame Master CS-5500, and 6) PPG Aerospace PR-2870. The small aluminum plates were used for the sealant removal performance testing with the sonic bath.

Screening of Alternatives

Due to the limited time and resources available to conduct the sealant removal performance testing, there were three screens applied to the 18 identified sealant removal alternatives to narrow down the number of alternatives to undergo performance testing. There were three different methods used for the screening of the sealant removal alternatives: 1) swab screen, 2) immersion screen, and 3) TURA screen. The first two screens (swab and immersion) are considered performance screens, and the third screen (TURA) is considered an environmental, health, and safety screen.

Swab Screen

The first screening method was to apply three drops of sealant remover to a sealant strip for a duration of two minutes, after which the strips were rubbed for one minute using foam swabs to determine if any sealant material was removed. Sealant removers that generated removal of some sealant material during the swab test were considered to pass this screen. Therefore, if there was any sealant residue that could be visually identified on the surface of the foam swab after the rubbing process was completed, then the sealant removal passed this screen. If there was no sealant residue that could be visually identified on the surface of the foam swab after the rubbing was completed, then the sealant removal failed this screen. Figure 1 shows the sealant strips and foam swabs used for this screening effort. These screens were conducted at the TURI Cleaning Laboratory using the large aluminum plates.

Figure 1: Sealant Screening (Swab Test)

Immersion Screen

The second screening method was an immersion test. The aluminum plates (see Figure 2) were immersed in glass beakers containing approximately 100 ml of liquid sealant remover for a dwell time of thirty minutes. The sealant strip was completely immersed in the sealant removal liquid.

Figure 2: Aluminum Plate Immersed in Sealant Removal Product

After the thirty minute dwell time, the aluminum plate was removed from the glass beaker, dried off with a paper towel, and scraped using a plastic scraper (see Figure 3). The scraping was conducted for a maximum duration of 3 minutes, after which the plates were visually inspected, and the estimated percentage of sealant removed was recorded. If the sealant strip was completely removed before the end of the three minute scraping process, then the sealant remover passed the screen and the time taken for complete sealant removal was recorded. If the sealant strip was not completely removed before the end of the three minute scraping process, then the sealant remover failed the screen; however the percentage of sealant removed after three minutes of scraping time was recorded for future comparison purposes. These screens were conducted at the TURI Cleaning Laboratory using the large aluminum plates.

Figure 3: Manual Sealant Scraping

TURA Screen:

The Massachusetts Toxics Use Reduction Act (TURA), adopted in 1989, is designed to protect public health and the environment while enhancing the competitiveness of Massachusetts businesses. TURA established a Toxic or Hazardous Substance List, often referred to as the TURA list. All toxic or hazardous substances regulated under TURA and subject to reporting and planning requirements are compiled into one list.

The TURA list was originally created based on two federal lists: Section 313 of the Emergency Planning and Community Right to Know Act (EPCRA) and Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA or "Superfund"). Any changes to the federal lists are incorporated into the TURA list. In addition, Massachusetts has made other changes to the list over time. (TURI, 2014b)

The TURA list is available at the following website:

http://www.mass.gov/eea/agencies/massdep/toxics/regulations/301-cmr-41-00-toxic-or-hazardous-substances-list.html

Each chemical ingredient used for the sealant removal products was checked with the TURA list. Two sealant removal products were found to contain N-Methyl-2-pyrrolidone (CAS # 872-50-4), a chemical that is on the TURA list. The two sealant removal products containing this chemical were:

- Finger Lakes Chemical Resin Eater

- Finger Lakes Chemical Graffiti Remover

Consequently, the above two sealant removal products were screened out from further consideration and evaluation.

Table 1 provides the results of the three screens performed for each of the eighteen potential alternatives.

Table 1: Sealant Remover Screening Results

|

Vendor |

Product |

Screen #1 Swab |

Screen #2 Immersion |

Screen #3 TURA |

|---|---|---|---|---|

|

Barco Products |

Soysafe Graffiti Remover |

Pass |

Pass |

Pass |

|

Bio Chem Systems |

Solsafe 245 |

Pass |

Fail (20% removal) |

N/A |

|

Bio Chem Systems |

Bio T Max |

Fail |

N/A |

N/A |

|

Dupont |

DBE6 |

Pass |

Fail (70% removal) |

N/A |

|

Eastman (Solutia) |

SkyKleen 1000 |

Pass |

Pass |

Pass |

|

Finger Lakes Chemical |

Resin Eater |

Pass |

Pass |

Fail |

|

Finger Lakes Chemical |

Graffiti Remover |

Pass |

Pass |

Fail |

|

Gemtek Products |

EZ Solv |

Pass |

Fail (60% removal) |

N/A |

|

Gemtek Products |

Maxisolv |

Fail |

N/A |

N/A |

|

Kreussler |

SolvonK4 |

Fail |

N/A |

N/A |

|

RPM Technology |

PolyGone® 310-AG |

Pass |

Pass |

Pass |

|

Socomore |

DS-108 |

Pass |

Fail (98% removal) |

N/A |

|

Socomore |

Diestone DLS |

Pass |

Pass |

Pass |

|

Spartan Chemical Company |

Graffiti Remover SAC |

Pass |

Fail (80% removal) |

N/A |

|

Spartan Chemical Company |

Green Solutions Floor Stripper |

Pass |

Fail (40% removal) |

N/A |

|

United Laboratories Int. |

Smart Solve 605 |

Pass |

Fail (40% removal) |

N/A |

|

Vertec Biosolvents |

Biogold |

Pass |

Fail (90% removal) |

N/A |

|

Westford Chemical Corp. |

BioSolve |

Pass |

Fail (95% removal) |

N/A |

N/A: Not applicable for further screening efforts because the product failed an earlier screening step.

After the three screens were applied, the four sealant removal products listed in Table 2 were the only sealant removal products that passed all three screens to qualify for the subsequent performance testing.

Table 2: Sealant Removal Products that Passed All Three Screens

|

Vendor |

Product |

|

Eastman (Solutia) |

SkyKleen 1000 (liquid) |

|

RPM Technology |

PolyGone® 310-AG |

|

Socomore (Dynamold, Magchem) |

Diestone DLS |

|

Barco Products |

Soysafe Graffiti Remover |

Performance Testing

The time required to scrape and remove the sealant strip from the aluminum plate was considered the key performance test for this research. Four factors were selected to systematically vary during our experiment in order to determine their effect on the scraping time: 1) sealant product, 2) sealant polymer chemistry, 3) sealant remover product, and 4) aluminum plate alloy.

The six sealant products evaluated are listed in Table 3. Five of the sealants had a polysulfide based polymer chemistry and one sealant has a polythioether based polymer chemistry.

Table 3: Six Sealants Included in the Evaluation

|

Vendor |

Product |

Specification |

Polymer Chemistry |

|---|---|---|---|

|

PPG Aerospace |

PS-870 |

MIL-PRF-81733 Type II Class 1 Grade A |

Polysulfide |

|

3M |

AC-735 |

MIL-PRF-81733 Type II Class 1 Grade B and AMS 3265 Class B |

Polysulfide |

|

PPG Aerospace |

PR-1775 |

AMS 3265 Class B |

Polysulfide |

|

PPG Aerospace |

PR-2870 |

MIL-PRF-81733 Type II Class 2 Grade B |

Polythioether |

|

Flame Master |

CS 5500N CI |

Not yet qualified |

Polysulfide |

|

PPG Aerospace |

PR-1440 |

AMS-S-8802 Type 2 Class B |

Polysulfide |

For the sealant remover, five different sealant removal produces were evaluated: The four sealant remover products that passed the screening process (SkyKleen 1000, PolyGone® 310-AG gel, Diestone DLS, and SoySafe Graffiti Remover), and toluene to be used as a baseline for comparison with the alternative products. For the aluminum alloy of the test coupon, the 6061 and 7075 alloys were evaluated.

Similar to the immersion test screening process, the aluminum plates were immersed in glass beakers containing approximately 100 ml of sealant remover for a dwell time of thirty minutes. The sealant strip was completely immersed in the sealant removal liquid. After the thirty minute dwell time, the aluminum plates were removed from the glass beaker, dried off with a paper towel, and scraped using a plastic scraper. The time to remove 100% of the sealant strip from the test coupon was recorded. The exception to this process was the use of the PolyGone 310-AG gel. The gel was applied with a foam swab to completely cover the sealant strip for a thirty minute dwell time. The PolyGone 310-AG gel contains the same chemical formulation as the liquid version and therefore was anticipated to provide similar results.

Table 4 shows the Design of Experiments used to evaluate the performance of the alternative sealant removal products.

Table 4: Design of Experiments for Performance Testing

|

Run |

Sealant |

Sealant Type |

Alloy |

Sealant Remover |

|---|---|---|---|---|

|

1 |

AC-735 |

Polysulfide |

7075 |

Diestone DLS |

|

2 |

CS5500 |

Polysulfide |

6061 |

Diestone DLS |

|

3 |

PR-1440 |

Polysulfide |

6061 |

Diestone DLS |

|

4 |

PR-1775 |

Polysulfide |

6061 |

Diestone DLS |

|

5 |

PS-870 |

Polysulfide |

6061 |

Diestone DLS |

|

6 |

PR-2870 |

Poylthioether |

7075 |

Diestone DLS |

|

7 |

AC-735 |

Polysulfide |

7075 |

PolyGone 310-AG gel |

|

8 |

CS5500 |

Polysulfide |

6061 |

PolyGone 310-AG gel |

|

9 |

PR-1440 |

Polysulfide |

7075 |

PolyGone 310-AG gel |

|

10 |

PR-1775 |

Polysulfide |

6061 |

PolyGone 310-AG gel |

|

11 |

PS-870 |

Polysulfide |

6061 |

PolyGone® 310-AG gel |

|

12 |

PR-2870 |

Poylthioether |

6061 |

PolyGone 310-AG gel |

|

13 |

AC-735 |

Polysulfide |

7075 |

SkyKleen 1000 |

|

14 |

CS5500 |

Polysulfide |

6061 |

SkyKleen 1000 |

|

15 |

PR-1440 |

Polysulfide |

7075 |

SkyKleen 1000 |

|

16 |

PR-1775 |

Polysulfide |

6061 |

SkyKleen 1000 |

|

17 |

PS-870 |

Polysulfide |

6061 |

SkyKleen 1000 |

|

18 |

PR-2870 |

Poylthioether |

7075 |

SkyKleen 1000 |

|

19 |

CS5500 |

Polysulfide |

6061 |

Soysafe G.R. |

|

20 |

PR-1440 |

Polysulfide |

6061 |

Soysafe G.R. |

|

21 |

PR-1775 |

Polysulfide |

6061 |

Soysafe G.R. |

|

22 |

PS-870 |

Polysulfide |

6061 |

Soysafe G.R. |

|

23 |

AC-735 |

Polysulfide |

7075 |

Soysafe G.R. |

|

24 |

PR-2870 |

Poylthioether |

7075 |

Soysafe G.R. |

|

25 |

AC-735 |

Polysulfide |

7075 |

Toluene |

|

26 |

CS5500 |

Polysulfide |

6061 |

Toluene |

|

27 |

PR-1440 |

Polysulfide |

6061 |

Toluene |

|

28 |

PR-1775 |

Polysulfide |

6061 |

Toluene |

|

29 |

PS-870 |

Polysulfide |

6061 |

Toluene |

|

30 |

PR-2870 |

Poylthioether |

6061 |

Toluene |

Results:

The Analysis of Variance (ANOVA) method was used for hypothesis testing. The null hypothesis used for this research was that the values of the response variable (scraping time) for different factor/level combinations within the design of experiments are the same for each combination. The alternative hypothesis is that the values of the scraping time for different factor/level combinations are not the same.

Alpha risk is the probability of rejecting the null hypothesis when it is actually true, resulting in a Type 1 error. Confidence level is defined as: 1 - alpha risk.

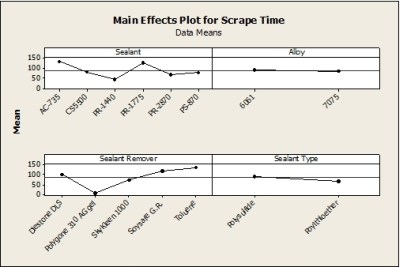

For the purposes of this research, the results were considered to be statistically significant if the confidence level was at least 95%, with a corresponding alpha risk of 5%. Therefore, if the p-value of the test statistic was less than the alpha risk (0.05), then the null hypothesis was rejected. Minitab software was used for the statistical analysis. Figure 4 shows the main effect results for the four different factors examined.

Figure 4: Results for Main Effects

The following is a summary of the statistical significance for the four factors investigated:

- There was no statistically significant difference (P value = 0.147) identified between the scraping time results for the different sealant products.

- There was no statistically significant difference (P value = 0.596) identified between the scraping time results for the different aluminum alloys used for the aluminum plates.

- There was no statistically significant difference (P value = 0.384) identified between the scraping time results for the sealant types (polysulfide and polythioether).

- There was a statistically significant difference (P value = 0.012) identified between the scraping time results of the different sealant removal products.

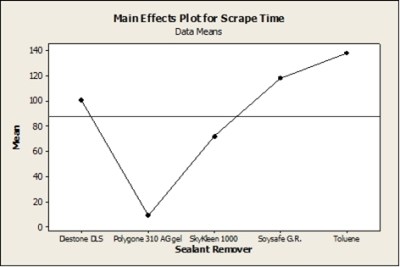

Figure 5 shows the mean scraping times for the five different sealant removal products that were included in the performance test. The mean scraping time was the lowest for the PolyGone 310-AG gel gel product (9 seconds). This was statistically significantly less than the mean scraping time for toluene (138 seconds). There was no statistically significant difference in scraping time between toluene and the following three alternatives: Diestone DLS (101 seconds), SkyKleen 1000 (72 seconds), and Soy Safe Graffiti Remover (118 seconds). Therefore, all four alternative sealant removal products evaluated have exhibited sealant removal performance comparable or better than that of toluene.

Figure 5: Mean Scraping Times for Sealant Removal

Ultrasonic Cleaning

The final phase of the performance testing was the use of an ultrasonic bath to evaluate the effects of agitation on the sealant removal process. The Branson 1510 Ultrasonic Cleaner was used for this testing. This type of cleaner transmits ultrasonic sound for enhanced cleaning of materials and parts. This ultrasonic cleaner has a frequency of 40 kHz. As the sound waves radiate though the solution in the tank, they generate high and low pressures within the solution.

There are two methods of ultrasonic cleaning: direct and indirect. The direct method involves filling the entire tank with the sealant remover and then inserting the aluminum plates directly into the tank. The indirect method involves partially filling the tank with water, pouring the sealant remover into a small beaker, placing the aluminum plates within the beaker, and then placing the beaker into the water filled tank. (Branson, 2014)

Since there was limited amounts of sealant removal samples available for this testing, the testing with ultrasonic bath was done using the indirect method. For each sealant and sealant remover combination, one test was done with the glass beaker in the ultrasonic bath (see Figure 6) and one was done without the ultrasonic bath for comparison purposes. Similar to the immersion test screening process, the aluminum test plates were immersed in glass beakers containing a sealant remover for a dwell time of thirty minutes. After the thirty minute dwell time, the aluminum plates were removed from the glass beaker, dried off with a paper towel, and scraped using a plastic scraper. The time to remove 100% of the sealant strip from the test coupon was recorded.

Figure 6: Sealant removal ultrasonic bath test

The ultrasonic bath test was conducted using the small aluminum plates (1” x 4”) made of 2024 aluminum alloy. Table 5 shows the testing results with and without the use of the ultrasonic bath test.

Table 5: Results of Ultrasonic Bath Test

|

Sealant Removal Product |

Sealant |

Scrape Time without Ultrasonic Bath (sec) |

Scrape Time with Ultrasonic Bath (sec) |

% Reduction in Scrape Time |

|---|---|---|---|---|

|

Gemtek SafeCare EZ Solv |

CS5500 |

12 |

5 |

58% |

|

SkyKleen 1000 |

AC-735 |

120 |

90 |

25% |

|

SkyKleen 1000 |

PR-1775 |

50 |

15 |

70% |

|

SoySafe Graffiti Remover |

PR-1775 |

90 |

8 |

91% |

There were not enough samples included in this test to achieve statistically significant results. However, based upon results of the four samples, it appears that the use of the ultrasonic cleaner may reduce the scrape time necessary to remove the sealant material.

Environmental, Health, and Safety (EHS) Evaluation:

The environmental, health, and safety impacts of the sealant removal products were evaluated using the Pharos Chemical and Material Library chemical hazard assessment tool and the Toxics Use Reduction Institute’s Pollution Prevention Options Assessment System (P2OASys).

Pharos Chemical and Material Library

The Pharos Chemical and Material Library (CML) was used for a rapid evaluation of the chemical ingredients contained in the sealant removal products. CML is an extensive online catalog of substances that identifies associated key health and environmental hazard information. The CML was developed by the Healthy Building Network to support its Pharos building product selection process. The CML primarily uses two types of lists to determine chemical hazards: 1) authoritative chemical hazard lists, and 2) restricted substances lists. The CML addresses the endpoints outlined below (CML, 2014).

Human Health Hazards:

- Carcinogenicity

- Mutagenicity/genotoxicity

- Reproductive toxicity

- Developmental toxicity

- Endocrine activity

- Acute mammalian toxicity

- Systemic toxicity/organ effects

- Neurotoxicity

- Eye irritation

- Skin irritation

- Respiratory sensitization

- Skin sensitization

Environmental Hazards:

- Acute aquatic toxicity

- Chronic aquatic toxicity

- Terrestrial ecotoxicity

- Persistent Bioaccumulative Toxicant (PBT)

- Global warming

- Ozone depletion

Physical Hazards:

- Flammability

- Reactivity

The CML then characterizes the hazard level of a chemical for each endpoint. Hazard is ranked on the following five step scale:

- Very high hazard

- High hazard

- Moderate hazard

- Low hazard

- Very low hazard

Table 6 provides a summary of the CML “Very High Hazard”, “High Hazard”, and “Medium Hazard” designations for each of the chemical ingredients used in the sealant removal products. The “low hazard” and “very low hazard” designations are not included in the table. Further information about the CML methodology can be found in the Chemical & Material Library (CML) Full System Description located at: https://www.pharosproject.net/uploads/files/PharosCMLSystemDescription.pdf

Table 6: CML Very High or High Hazards

|

Sealant Removal Product |

Chemical Ingredients (CAS #) |

Chemical Hazards (Listing of CML “Very High Hazard” or “High Hazard” Ratings Only) |

|---|---|---|

|

Toluene |

Toluene (108-88-3) |

Toluene is a high hazard for developmental toxicity, reproductive toxicity, respiratory sensitizer, acute mammalian toxicity, skin irritation, acute aquatic toxicity, and flammability.

Toluene is a medium hazard for endocrine disruption, neurotoxicity, eye irritation, organ toxicant, and terrestrial ecotoxicity. |

|

Methylene chloride |

Methylene chloride (75-09-2) |

Methylene chloride is a high hazard for cancer, acute mammalian toxicity, eye irritation, and acute aquatic toxicity.

Methylene chloride is a medium hazard for endocrine disruption, skin irritation, organ toxicity, chronic aquatic toxicity, and terrestrial ecotoxicity. |

|

N-propyl bromide |

N-propyl bromide (106-94-5) |

N-propyl bromide is a high hazard for cancer, developmental toxicity, reproductive toxicity, acute mammalian toxicity, eye irritation, skin irritation, flammability, and ozone depletion.

N-propyl bromide is a medium hazard for respiratory sensitizer, neurotoxicity, organ toxicant, acute aquatic toxicity, and chronic aquatic toxicity. |

|

PolyGone® 310-AG gel |

Dimethylacetamide (127-19-5) >60%

Gamma-butyrolactone (96-48-0) 5% - 25%

Additive (proprietary) 1% - 10% |

Dimethylacetamide is a high hazard for developmental toxicity, reproductive toxicity, and acute mammalian toxicity.

Dimethylacetamide is a medium hazard for eye irritation and flammability.

No high hazard endpoints identified for gamma-butyrolactone.

Gamma-butyrolactone is a medium hazard for acute mammalian toxicity, eye irritation, acute aquatic toxicity, and terrestrial ecotorixity. |

|

Diestone DLS |

Ingredient 1

Ingredient 2

Ingredient 3

Socomore has requested that the ingredient names for the Diestone DLS product to not be disclosed in this report. If you would like a copy of the Diestone DLS Safety Data Sheet or ingredient list then please contact: Juliana Garcia at jgarcia@socomore.com |

No high hazard endpoints identified for Ingredient 1 and Ingredient 2.

Ingredient 1 is a medium hazard for developmental toxicity, neurotoxicity, acute mammalian toxicity, eye irritation, skin irritation, and flammability.

Ingredient 2 is a medium hazard for developmental toxicity, eye irritation, and flammability.

Ingredient 3 is a high hazard for PBT, cancer, gene mutation, respiratory sensitization, and acute mammalian toxicity. (See Note 1)

Ingredient 3 is a medium hazard for flammability.

|

|

SkyKleen 1000 |

Dimethyl glutarate (1119-40-0) 55% - 75%

Dimethyl succinate (106-65-0) 15% - 35%

Dimethyl adipate (627-93-0) 5% - 25% |

No high hazard endpoints identified for all ingredients.

Dimethyl glutarate is a medium hazard for eye irritation and acute aquatic toxicity.

Dimethyl succinate is a medium hazard for eye irritation, acute aquatic toxicity and flammability.

Dimethyl adipate is a medium hazard for acute mammalian toxicity and terrestrial ecotoxicity.

|

|

SoySafe Graffiti Remover |

Proprietary ingredients |

Not applicable because chemical ingredients are not provided. (See Note 2) |

Note 1:

According to a letter from the manufacturer of Diestone DLS (Socomore)to the report authors on September 25, 2013:

Ingredient 3 “is a global reference for white spirit. This official category makes no distinction between white spirits containing aromatic hydrocarbons and white spirits which have been specially treated to eliminate those much talked about aromatic solvents.

However the Regulation (EC) no. 1272/2008 2001/59/CE of 31 December 2008, Appendix VI Paragraph 1.1.3.1. Note P, takes into account this fact:

The carcinogenic or mutagenic classification cannot apply if the substance contains less than 0.1 weight/weight of benzene (EINECS no 200-753-7)

Of course we are in possession of all the certificates from our suppliers indicating that the rate of benzene is actually inferior to 0.1% in volume in this white spirit.”

Note 2:

Section II: Hazardous Ingredients of the Barco Products Material Safety Data Sheet (Barco, 1999) for the SoySafe Graffiti Remover product states the following:

“None as defined under the U.S. OSHA Hazard communication standard (29 CFR 1910, 1200) or the Canadian Hazardous products Act S.C. 1987, C.30 (Part I)”

TURI Pollution Prevention Options Assessment System

The Pollution Prevention Options Assessment System (P2OASys) was developed by TURI as a systematic tool to help companies determine whether the toxics use reduction options they were considering could have unforeseen negative impacts.

P2OASys allows companies to assess the potential environmental, worker, and public health impacts of alternative technologies that could be implemented to reduce toxic chemical use. Embedded formulae in P2OASys provide a numerical hazard score for the company's current process and the identified options, which can then be combined with other information sources and professional judgment to make decisions on the choice of alternatives. The tool evaluates chemicals and/or processes in eleven hazard areas, with each hazard area including one or more characteristics. There are a total of 61 characteristics that are evaluated in P2OASys. Table 7 lists the eleven hazard areas and the associated 61 characteristics used in P2OASys.

Table 7: P2OSASys Hazard Areas and Characteristics

|

Hazard Area |

Characteristic |

|---|---|

|

Acute human effects |

Inhalation LC50, PEL/TLV, PEL/TLV (dusts/particles), IDLH, respiratory irritation, oral LD50, dermal irritation, skin absorption, dermal LD50, ocular irritation |

|

Chronic human effects |

Reference dose (RfD), carcinogen, mutagen, reproductive effects, neurotoxicity, developmental effects, respiratory sensitivity/disease, other chronic organ effects |

|

Physical hazards |

Heat, noise generation, vibration, ergonomic hazard, psychosocial hazard |

|

Aquatic hazards |

Water quality criteria, aquatic LC50, fish NOAEC, plant EC50, observed ecological effects |

|

Persistence/bioaccumulation |

Persistence, BOD half life, hydrolysis half-life, bioconcentration, bioconcentration factor (BCF) |

|

Atmospheric hazard |

Greenhouse gas, ozone depletor, acid rain formation, NESHAP |

|

Disposal hazard |

Landfill, EPCRA reportable quantity, incineration, recycling |

|

Chemical hazard |

Vapor pressure, solubility in water, specific gravity, flammability, flash point, reactivity, pH, corrosivity, high pressure system, high temperature system, mixture/reaction potential, odor threshold, volatile organic compound |

|

Energy and resource use |

Non-renewable resource, water use, energy use |

|

Product hazard |

Upstream effects, consumer hazard, disposal hazard |

|

Exposure potential |

Exposure potential |

The individual hazard rating values for the 61 characteristics associated with the hazard areas were determined using the following data sources: Material Safety Data Sheet (MSDS) information, Technical Data Sheet (TDS) information, PBT Profiler, IPCC Greenhouse gas list, EPA Ozone Depletor list, U.S. EPA NESHAP Listing, and professional judgment. These data sources provided values for many, but not all of the 61 characteristics. If these data sources did not provide information for a particular characteristic (e.g. IDLH), then a value for that characteristic was not included in deriving the P2OASys score. Additional data sources such as REACH Dossiers, a search of current scientific literature, and access to various chemical hazard lists and databases could be evaluated to potentially provide data for more characteristics included in P2OASys. However, due to funding and time constraints, these additional sources were not evaluated as part of this study.

The values for the characteristics of each sealant remover were entered into the P2OASys tool. A corresponding score was then computed by the P2OASys system for each characteristic and hazard area. The score for each characteristic and hazard area ranges from 2 to 10, with a score of “2” being the best or safest, and a score of “10” being the worst or least safe. In general, a score of “2” is considered a low hazard, a score of “4” is considered a low/medium hazard, a score of “6” is considered a medium hazard, a score of “8” is considered a medium/high hazard, and a score of “10” is considered a high hazard.

The final score is the summation of the eleven hazard area scores. The weighted final score is the final score divided by the number of hazard areas with scores. For example, the weighted final score for toluene is calculated as follows:

Weighted final score = 78/11 = 7.1

Further information about the P2OASys scoring method is located at:

http://www.turi.org/Our_Work/Research/Alternatives_Assessment/Chemical_Hazard_Comparison_Tools/P2OASys_Tool_to_Compare_Materials

The individual P2OASys hazard rating values for each of the seven sealant removal products are provided in Tables 8, 9, and 10.

Table 8: P2OASys Scores for Toluene, nPB, and Methylene Chloride

|

Hazard Area |

Toluene |

nPB |

Methylene Chloride |

|---|---|---|---|

|

Acute human effects |

9 |

8 |

8 |

|

Chronic human effects |

10 |

8 |

8 |

|

Physical hazards |

6 |

6 |

6 |

|

Aquatic hazard |

7 |

5 |

3 |

|

Persistence/bioaccum. |

4 |

5 |

5 |

|

Atmospheric hazard |

6 |

10 |

6 |

|

Disposal hazard |

6 |

6 |

6 |

|

Chemical hazard |

10 |

6 |

8 |

|

Energy/resource use |

6 |

8 |

8 |

|

Product hazard |

8 |

6 |

6 |

|

Exposure potential |

6 |

6 |

6 |

|

Final Score |

78 |

74 |

70 |

|

Weighted Final Score |

7.1 |

6.7 |

6.4 |

The three commonly used sealant removers (toluene, nPB, and methylene chloride) received P2OASys weighted final scores in the range of 6.4 to 7.1. Therefore, these three sealant removers are considered to be a medium to high hazard chemical in aggregate for all eleven hazard areas.

Table 9: P2OASys Scores for SkyKleen 1000, PolyGone 310-AG gel, and

Diestone DLS

|

Hazard Area |

SkyKleen 1000 |

PolyGone 310-AG gel |

Diestone DLS |

|---|---|---|---|

|

Acute human effects |

8 |

9 |

5 |

|

Chronic human effects |

4 |

7 |

4 |

|

Physical hazards |

3 |

4 |

3 |

|

Aquatic hazard |

6 |

2 |

2 |

|

Persistence/bioaccum. |

3 |

4 |

4 |

|

Atmospheric hazard |

2 |

2 |

2 |

|

Disposal hazard |

4 |

4 |

4 |

|

Chemical hazard |

5 |

6 |

9 |

|

Energy/resource use |

3 |

6 |

6 |

|

Product hazard |

2 |

2 |

2 |

|

Exposure potential |

6 |

6 |

6 |

|

Final Score |

46 |

52 |

47 |

|

Weighted Final Score |

4.2 |

4.7 |

4.3 |

The three alternative sealant remover products (SkyKleen 1000, PolyGone 310-AG gel, and Diestone DLS) received P2OASys weighted final scores in the range of 4.2 to 4.7. Therefore, these three sealant removers are considered to be a low to medium hazard chemical in aggregate for all eleven hazard areas.

Table 10: P2OASys Scores for SoySafe Grafitti Remover

|

Hazard Area |

SoySafe G.R. |

|---|---|

|

Acute human effects |

8 |

|

Chronic human effects |

NV |

|

Physical hazards |

3 |

|

Aquatic hazard |

NV |

|

Persistence/bioaccum. |

NV |

|

Atmospheric hazard |

2 |

|

Disposal hazard |

3 |

|

Chemical hazard |

7 |

|

Energy/resource use |

3 |

|

Product hazard |

3 |

|

Exposure potential |

6 |

|

Final Score |

35 |

|

Weighted Final Score |

4.4 |

For the chronic human effects, aquatic hazard, and persistence/biocaccumulation hazard areas the SoySafe Grafitti Remover product received a score of “No Value” because of limited information on the MSDS and the non-disclosure of the actual ingredients of the product. In this instance, the Weighted Final Score is calculated as follows:

Weighted final score = 35/8 = 4.4

The SoySafe Grafitti Remover score could potentially change significantly once the additional data is obtained to complete a score for the chronic human effects, aquatic hazard, and persistence/biocaccumulation hazard areas.

Cost Information

The price information for the various sealant removers was not included in this study for the following reasons:

- The pricing for these products may change over time.

- Many of the products are sold in bulk, and have certain minimum quantities for purchase.

- The price of the products may vary with the quantity of the product purchased as well as the business relationship between the purchasing entity and vendor.

- The cost of purchasing the sealant remover is only one of many factors affecting the overall cost of the sealant removal process. The other factors include: labor costs, employee training costs, personal protection equipment, scraping materials, and ventilation costs.

Conclusions

For the technical performance of the sealant removers, the PolyGone 310-AG gel product had the best results for all the sealant removers evaluated. The Diestone DLS, SkyKleen 1000, and Soy Safe Graffiti Remover products exhibited sealant removal performance comparable to that of toluene.

For environmental, health, and safety considerations, the SkyKleen 1000, PolyGone 310-AG gel, and Diestone DLS products had safer chemical profiles than toluene, nPB, and methylene chloride. The Soy Safe Graffiti Remover could not be fully evaluated because of limited information on the MSDS and the non-disclosure of the actual ingredients of the product.

Acknowledgements:

Heidi Wilcox from TURI for contacting some of the sealant removal vendors and ordering samples for performance testing.

Paul Robinson from the U.S. Army Aviation and Missile Command (AMCOM) G-4 Environmental Team for providing technical input and providing previous sealant removal test results.

Dhimiter Bello from the College of Health Sciences at the University of Massachusetts Lowell for the use of toluene and fume hoods in his lab for conducting performance testing for the toluene samples.

Sources:

Toxics Use Reduction Institute (a), website accessed on July 14, 2014.

http://www.turi.org/Our_Work/Cleaning_Laboratory/Does_It_Clean/CleanerSolutions_Database/Database-Previews/

Toxics Use Reduction Institute (b), website accessed on July 14, 2014. http://www.turi.org/Our_Work/Toxic_Chemicals/Chemical_Lists

Branson Operator’s Manual for Ultrasonic Cleaners: Models 1510, 2510, 3510, 5510, and 8510, CPN0214-142, Rev. B. Website accessed on July 14, 2014.

http://www.uvm.edu/cosmolab/om/BransonicultrasoundB.pdf

Pharos Project of the Healthy Building Network, Chemical & Material Library (CML) Full System Description, April 22, 2014. Accessed on July 15, 2014 at: https://www.pharosproject.net/uploads/files/PharosCMLSystemDescription.pdf

Barco Products, Soy Safe Graffiti Remover Material Safety Data Sheet, M.E.S – 3-24-99.

Socomore, Diestone DLS – 28280A Safety Data Sheet, Version February 20, 2013.

RPM Technology, PolyGone 310-AG gel Material Safety Data Sheet.

Solutia Inc., SkyKleen 1000 Material Safety Data Sheet, July 12, 2011 Version 6.1/EN.

Sigma Aldrich, Dichloromethane Safety Data Sheet, Revision May 12, 2014, Version 5.5.

Sigma Aldrich, 1-Bromopropane Safety Data Sheet, Revision July 1, 2014, Version 4.8.

Sigma Aldrich, Toluene Safety Data Sheet, Revision February 24, 2014, Version 5.5.

Enviro Tech International, Ensolv Material Safety Data Sheet, February 17, 2005.

RELATED CONTENT

-

Conversion Coatings: Phosphate vs. Zirconium

Both phosphate-based and zirconium coatings have their advantages, but zirconium is fast becoming the pretreatment of choice.

-

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

-

Pretreatment for Painting

Better adhesion, enhanced corrosion and blister resistance, and reduced coating-part interactions make pretreatment a must.