Automated Electroplating Systems

Simultaneous engineering reduces energy and resource consumption.

#basics #energy

Finishing system operators can deliver repeatable quality with reduced labor and improve profitability by installing properly sized, resource-efficient plating and/or coating systems. This is accomplished by simultaneous engineering of tank, hoist and labor limits to achieve specific quality and productivity requirements. Development requires precise knowledge of current and future throughput requirements, chemistry supplier’s process sequence, including all process and rinse baths with immersion times, temperatures, and work package selection (rack, basket or barrel). These requirements must be coupled with efficient material handling to complement load/unload labor.

With throughput, work package, and a process sequence well-defined, external limitations such as ceiling height, floor space, chemistry-specific area/volume ratios, and/or rectifier amp-square-foot (ASF) requirements can be considered. Together, they influence hoist capacity, loads per hour and the number of process cells required.

Featured Content

For rack electroplating, your chemistry supplier will recommend inter-part spacing needed to optimize throwing power, typically 1.5 to 2.5 times the part diameter or width (Figure 1). Coating racks are not bound by such limitations, and may be densely packed provided parts don’t touch. Spacing must be known in advance to determine rack density (parts per square foot) to assure repeatable quality. Throughput is a function of parts-per-rack times loads-per-hour. It is the primary driver for development of the three-dimensional work package, stated as width × height × direction-of-travel (DOT). Maximum part load, together with the rack and carrier bar weight, determine hoist capacity.

Barrel work is metered in pounds to meet surface area fill for electroplating, or volume fill for electroless coating (Figure 2). Time-to-plate is slower for barrels compared with racks, where throwing power is limited by perforation size, percentage of open space, and part surface area exposed to anodes. Coating barrels are not so limited: Barrel fills are typically 33 percent for plating and 80 percent for coatings by volume. Be aware that there exists an inverse relationship between part size and packing density. For example, the packing density (parts per cubic foot) for ¼-inch diameter by ½-inch-long fasteners includes a significantly higher count and surface area than the packing density of a cubic foot of ½-inch diameter by 4-inch-long fasteners. Surface area, weight and packing density must be known for each part early in the machine development process. The three-dimensional barrel work package is stated as diameter × width (or length), from which volume fill is calculated. The barrel, super structure, and maximum-designed parts fill determine hoist capacity.

Tank dimensions are dictated by the work package size and vary depending on content such as heating/cooling elements, ultrasonic transducers, spargers, eductors, agitation devices and tank monitoring sensors. Circulation pumps and filters are sized based on turns per hour, defined as the number of gallons per tank times turns; a value wholly dependent on tank volume. Heating and/or cooling requirements are dependent upon bath temperature and immersed work package mass × loads per hour. Together, they determine thermal loading and boiler and/or chiller size. The American Council of Governmental Industrial Hygienists dictates ventilation and scrubber type based on tank surface area, chemistry type, concentration and temperature.

Only after these basics are established can resource-saving machine features be considered. One of the single greatest opportunities is to limit tank surface area, which reduces evaporative, thermal and floor space consumption. In general, wider, taller work packages with the shortest possible DOT will deliver the most efficient use of labor, energy, chemistry, water and space. Furthermore, finishing systems make best use of resources when run around the clock.

Computer Driven Automation

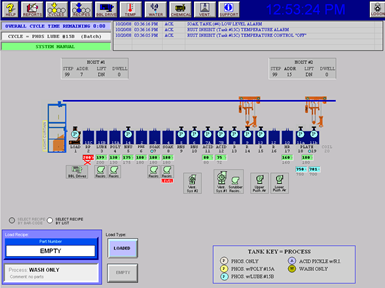

Figure 3. Computer controls automatically monitor, store and export load-by-load quality data for immersion times, tank temperatures, rectifier settings, chemistry adds, rinse water replenishment, barrel rotation/oscillation, ventilation/air makeup, wastewater treatment, and more.

Computer controls automatically monitor, store and export load-by-load quality data for immersion times, tank temperatures, rectifier settings, chemistry adds, rinse water replenishment, barrel rotation/oscillation, ventilation/air makeup, wastewater treatment, and more (Figure 3). The goal is to install advanced machine features with complimentary controls to enable precise resource management, reduce operator input errors (and corrective actions), and eliminate manual quality monitoring/reporting to further reduce labor cost.

Recipe-driven individual plate cell rectification enables precise, repeatable plate thickness for every load, regardless of part count for rack plating, or by weight for barrel plating. Barcode-loaded recipes enable the computer to calculate surface area on a discreet part number basis, and adjust process parameters accordingly. Manually or automatically entered rack part count assures precise ASF delivery. Barrel weight is automatically verified by load cells during the fill operation, likewise assuring precise ASF delivery.

High-efficiency, VFD-controlled hoist motor/drive combinations, guided with absolute linear encoders, provide the smoothest possible motion profiles, eliminate rack or barrel shake, reduce motor brake wear and reduce electrical energy consumption. Corrosion-proof belt lifts reduce drag and dramatically extend maintenance intervals. Integration of these features significantly reduces operation and maintenance costs.

Water and Chemistry Reduction

Given today’s pressure to conserve earthly resources, it’s prudent to make efficient use of water and chemistry to the greatest extent possible. Advanced fluid management devices and controls can dramatically reduce consumption of both.

Load-by-load rinse water replenishment can optimize water consumption on a recipe-driven basis, if desired. The ultimate goal is to reduce process water usage, which in turn reduces wastewater treatment loading and its associated chemistry. Load-by-load recipe-driven chemistry addition eliminates saw-tooth fluctuations common with less frequent additions. An integrated PC/HMI is needed to recognize and select recipes, and adjust for rack or barrel fill variation. Ethernet-based controls allow local or remote replenishment adjustments any time during machine operation.

Your chemistry supplier may recommend RO water due to unsuitable local water quality, or it may be required for a specific process chemistry. RO equipment requires floor space, energy, and water (appx. 30 percent rejection rate). Makeup, addition, and/or replenishment for evaporative losses may be partially or completely accomplished with dragout recovery, further reducing the need for fresh or RO water.

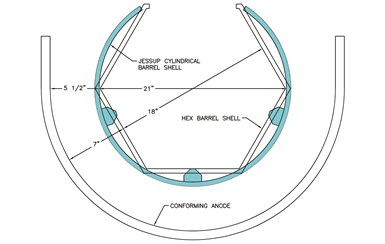

Figure 4. Cylindrical plating (and coating) barrels offer a 17 percent increase in volume and more consistent anode-to-work relationship compared to hex-style barrels of the same size.

Careful consideration should be given to plating and coating barrel design. Cylindrical plating (and coating) barrels offer a 17-percent increase in volume and more consistent anode-to-work relationship compared to hex-style barrels of the same size (Figure 4). Perforation size and shape greatly affect time to drain. Finally, up-barrel rotation drains directly to the process tank ,reducing carryover, a feature especially important for parts known to cup solution. Up-barrel rotation should be considered mandatory in today’s demanding parts finishing environment.

Wastewater Treatment Basics

Figure 5. Computer-controlled wastewater treatment systems manage rinse waters, process tank dumps and treatment resources with precision.

Critical to resource reduction strategy is a basic understanding of water consumption drivers. Water use begins with total purchased and ends the total water discharged, a variable expense that directly affects operating cost. Computer controlled wastewater treatment systems manage rinse waters, process tank dumps and treatment resources with precision (Figure 5).

Wastewater treatment sizing is almost purely a function of part surface area. Water treatment experts find one gallon of dragout is generated for every 1,000 square feet of surface area processed, and that each gallon of dragout requires approximately 600 gallons of rinse water to maintain process quality. Fortunately, most parts are designed in CAD today, so area and water consumption can easily be calculated.

To minimize wastewater treatment demand, machines should be designed to reduce dragout and carryover by any means possible. Opportunities include quick draining rack, barrel or basket designs with increased drain dwells and/or programmable drip trays. Tipping, tilting, or vertical oscillation for racks; optimized perforations with up-rotation for barrels dramatically reduce dragout/carryover. Recirculating spray pre-clean tanks, multiple soak clean tanks, two rinses minimum between baths, or three between alkaline and acid chemistry, and top sprays are features that reduce dragout and carryover losses.

Ventilation and Air Makeup Management

Figure 6. Machine enclosures can reduce total volume of ventilation air required and reduce or eliminate the effect of transient air flows, which otherwise adversely affect push-pull ventilation systems.

Variable frequency drive (VFD) ventilation blower motor controls can slave ventilation speed to tank temperatures. This offers the opportunity to slow ventilation output as tanks cool during overnight or weekend shutdowns. Additional savings can be achieved if VFD controls are added to air makeup system blowers for integration with the ventilation system.

Machine enclosures can reduce total volume of ventilation air required and reduce or eliminate the effect of transient air flows, which otherwise adversely affect push-pull ventilation systems (Figure 6). Operator safety is improved because the ventilation barrier is located between the catwalk and automation.

Control, Monitoring, Recording, Reporting

PC/HMI operation of finishing systems should be considered standard for all finishing systems. Nadcap and ISO compliance is assured if the machine is equipped with appropriate sensor technology. Data such as tank temperatures, immersion times, rectification, pH, conductivity, rotation/oscillation speed and/or duration, chemistry and water additions, drain dwells, and dryer temps are collected, stored, and exported to the customer database for analysis and report generation.

From an operational standpoint, engineered process cycles offer the most efficient production performance, though mixed processes with variable plate time cycles are available at the cost of some productivity. Most operators prefer fixed production rates so load/unload operations and external logistics remain unaffected.

For ease of management, performance monitoring may include shift reports for total time and number of cycles run, tracking of automatic versus manual operation, load/unload delays, and fault data.

To speed correction of unexpected stoppages, a well-designed control system will provide automatic system diagnostics. Detailed screens should display fault location and actions needed to quickly restore production. Internet-based remote monitoring further expedites troubleshooting and repairs.

Regardless of operational strategy, machine operation must be simple and intuitive. A user-friendly, multi-lingual, touchscreen machine interface is a necessity in today’s finishing environment. An industrial PC with Windows-based software enables easy PLC interface without the need for a programmer.

The need for simultaneous engineering is now well established for complex plating and coating systems. Great news for OEMs, tiers and job shops is that reasonably priced, commercially available technology can reduce ongoing energy, water and chemistry consumption without sacrificing quality, thus improving the profitability of finishing system operations.

RELATED CONTENT

-

Robot-Ready Grinding Systems for High-Speed Production

Advanced rotary surface grinders now come “robot-ready” to facilitate integration with third party robotic arms and fully automate the process from loading to unloading.

-

Indonesian Plater Finds Fast Success in Auto Market

This father/son team, inspired by inventor Michael Faraday, focuses on anti-corrosion methods and automated processes to help their Indonesian plating business flourish.

-

The Real Cost: C-Hooks Versus Parts Racks

Industrial finishing line consultant Dan Davitz discusses the advantages of parts rack over the use of C-hooks for your paint or powder coating line.