Axalta Launches Mobile Color Matching App for Powder Coaters

The free tool allows users to scan any surface and easily match it to an Alesta stock powder coating hue which increases productivity by eliminating the wait for a sample powder or color chip delivery.

#curing #masking

Featured Content

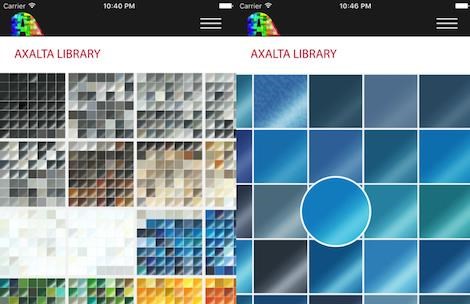

Axalta Coating Systems has launched a color matching mobile app,available on iOS and Android platforms. Axalta’s Axs free color matching app offers powder coating professionals a constellation of colors in the palm of their hand.

The free tool allows users to scan any surface and easily match it to an Alesta stock powder coating hue which increases productivity by eliminating the wait for a sample powder or color chip delivery. The app also gives users the option to request additional information such as product codes, chemistry details, or the opportunity to order color chips delivered directly to them.

“Our new and exciting color matching app provides the powder coating industry with a quick and simple way to scan a color and select the best Axalta match,” said Kristen Boyd, Axalta’s Marketing Manager for powder products. “The technology embedded in Axs will save customers time and provide quicker and easier color selections.”

You can find the Axs color matching app on the Apple App Store and Google Play. For more information about Axalta powder coatings, visit www.axalta.us/powder.

RELATED CONTENT

-

The Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

-

Understanding Infrared Curing

Infrared cure is gaining increased attention from coaters as a result of shorter cure cycles and the possibility of smaller floor space requirements when compared to convection oven curing.

-

Masking for Surface Finishing

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided. This article covers the many aspects of masking for metal finishing, including applications, methods and the various types of masking employed.