Biological Wastewater Treatment for Industrial Applications

With tightening limits on nutrients and Biological Oxygen Demand (BOD), is a small scale biological system right for your industrial facility?

#research #surfin

A Synopsis* of a Presentation given at SUR/FIN 2019 (Rosemont, Illinois) by Robin Deal** Hubbard-Hall Inc. , Inman, South Carolina, USA

Editor’s Note: The following is a synopsis of a presentation given at NASF SUR/FIN 2019, in Rosemont, Illinois on June 3, 2019 in Session 3, Waste Water Usage / Waste Management Minimization. A pdf of this brief can be accessed and printed HERE; the complete Powerpoint presentation is available by clicking HERE.

ABSTRACT

With tightening limits on nutrients and Biological Oxygen Demand (BOD), is a small scale biological system right for your industrial facility? We will explore the ins and outs of biological wastewater treatment and how it fits into the industrial world around us. We will look at system sizes and requirements, bacteria and their capabilities, and how to successfully treat via physical/chemical means and still use bacteria as a final polish for your needs.

Featured Content

Introduction

Discharge permits are focusing more on Biological Oxygen Demand (BOD) and nutrient removal than metal removal. With this trend, we can no longer focus on just meeting the metal removal requirements. We must now focus on how to continue to meet the metal removal requirements while also meeting new BOD and nutrient removal requirements. This cannot always be done via physical/chemical means.

Enter the world of bacteria. These amazing creatures live to eat what we no longer find desirable in water. Special blends of bacteria can consume enough phosphorus to make it nondetectable in testing. While they do this, they also consume nitrogen and BOD. What types of bacteria can do this? What are their needs to stay healthy and alive long enough to do their job for us? How can an industrial manufacturer, whose water is often deadly to bacteria, utilize them in small tight spaces? We will explore these questions, see photos of healthy bacteria, and discuss how to utilize them for your needs in detail.

Terminology

In order to properly discuss the ins and outs of biochemical wastewater treatment, it is important to review the nomenclature involved.

BOD5 measures the quantity of biodegradable organic matter contained in water. This biodegradable organic matter is evaluated using the oxygen consumed by the microorganisms involved in natural purification mechanisms.

Chemical oxygen demand, or COD, is one of the parameters of water quality. It represents the quantity of oxygen needed to oxidize all of the organic matter contained in water.

TKN (Total Kjeldahl Nitrogen) is the total concentration of organic nitrogen and ammonia.

The TP, or total phosphorus, is a sum parameter that shows the organic and inorganic phosphorus compounds in water.

Total Suspended Solids (TSS) is a measurement of the total solids in a water or wastewater sample that are retained by filtration.

Categorical pretreatment standards [paraphrased from 40 CFR 403.6] are standards specifying the quantity, concentration or pollutant properties of pollutants that may be discharged to publicly-owned treatment works (POTWs). EPA promulgates pretreatment standards for specific industry categories in accordance with CWA section 307. These standards are codified in 40 CFR chapter I, subchapter N, Parts 405–471.

Local limits [40 CFR 403.5(c)] are specific discharge limits developed and enforced by POTWs on industrial or commercial facilities (IUs) to implement the general and specific discharge prohibitions listed in 40 CFR 403.5(a)(1) and (b).

These are important because local authorities are really tightening the belt for industrial users to try to offset some of these pollutants. They are allotting surcharges to the tune of tens of thousands of dollars a month in some cases where the industry cannot meet the new limits that have been set in places.

Surcharges are additional fees charged to industrial users above and beyond the normal discharge fees. These fees are collected to help offset the cost of the treatment of the wastewater sent to the city’s treatment plant. The problem with this is that, if an industrial user is sending already treated water to the city, then the city is charging the industrial user to treat the same wastewater a second time. The industrial user is paying the city to do what their own treatment plant is failing to do while still paying for their treatment plant to run. This is not LEAN Wastewater Management.

Fines are assessed when an industrial user sends noncompliant wastewater to the city treatment plant. These are usually seen when the wastewater damages the treatment plant and are set. When big enough, jail time can accompany fines.

The current situation

Traditionally, physical and chemical treatments have worked for industrial users - so far. These processes have allowed metal finishers to remove heavy metals such as chromium, nickel, zinc, lead, cadmium, etc., successfully. These systems have played a huge part in allowing our environment to move past the early days of industrial revolution where rivers were on fire, smells were horrendous, and people could not safely drink the water. These systems will continue to play a vital role in all metal finishing companies around the world.

As focus is moving away from metals and inorganic contaminants, we have to shift our way of thinking on how industrial wastewater treatment plants look and work. We will, for the foreseeable future anyway, still need those physical/chemical systems for pretreatment, but they will need to have a secondary treatment as well.

Treatment technologies

Biological wastewater treatment comes in many shapes and sizes, including:

- Activated sludge plant (ASP)

- Rotating disc system.

- Submerged aerated filter (SAF)

- Suspended Media Filters (SMF)

- Sequencing batch reactor (SBR)

- Non-electric filter.

- Trickling filter

There are all types of wastewater treatment plants out there. When we think of them as biological treatment plants, we see in our mind these huge plants that take up hundreds of acres and need a lot of operators and attention. We think of the cities we discharge to and how huge they are in comparison to our industrial plants. We think bacteria are picky creatures and easy to kill. But, some of them can be fitted for industrial usage.

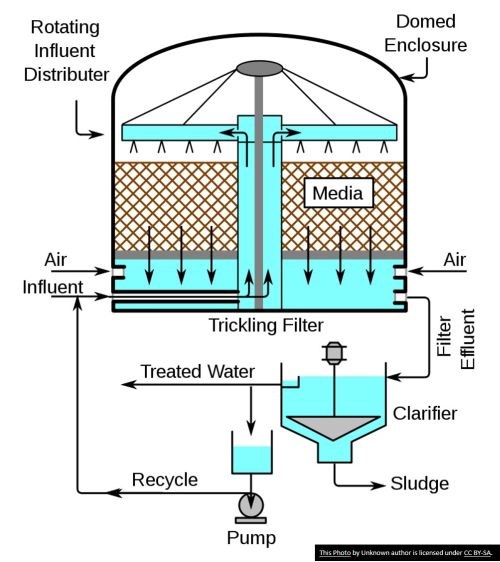

Trickling filters: One example is an industrial trickling filter,1,2 shown in Fig. 1. It involves a treatment process in which wastewater trickling over media enables the formation of slimes or biomass which contain organisms that feed upon and remove wastes from the water being treated (Office of Water Programs, CSU, Sacramento).

Figure 1 - Schematic diagram of a trickling filter.

Trickling filters are specified by loading rate (i.e., capacity). Low rate filters are used for loading less than 25 lb. BOD5 per 1000 ft3/day with a BOD removal efficiency of 80-90%. Intermediate trickling filters handle up to 400 lb. BOD5 per 1000 ft3/day with a BOD removal efficiency of 50-70%. High rate filters handle a maximum organic loading of 100 lb. BOD5 per 1000 ft3/day with a BOD removal efficiency of 65-85%. Roughing filters allow a significant amount of soluble BOD to bleed through filter loads between 100 and 300 lb.

Trickling filters do come with problems, including odors, ponding, filter flies and icing. Overall however, they provide the lowest cost for maintenance and operation of any bio system.

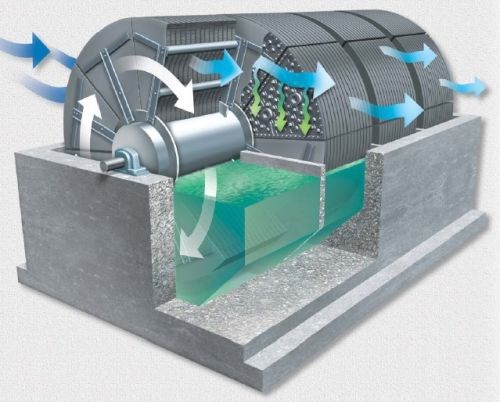

Rotating biological contactor: A rotating biological contactor (RBC) is a biological treatment device in which a population of microorganisms is alternately exposed to wastewater and then air (oxygen) to promote growth of the organisms as they oxidize the waste solids (Fig. 2)(Office of Water Programs, CSU, Sacramento).

Figure 2 - Rotating biological contactor (Figure courtesy of Walker Process Equipment).

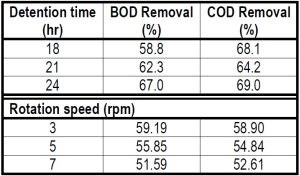

Performance data for a modified rotating biological contactor fitted with perforated baffles is shown in Table 1.3 Efficiency values for both BOD and COD are given versus detention time and rotational speed.

Table 1 - BOD / COD removal rates for a rotating biological contactor.

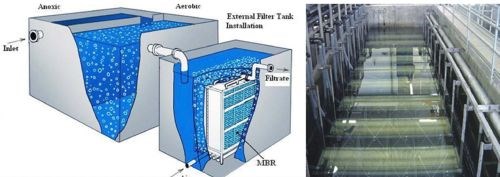

Membrane bioreactor: A membrane bioreactor (MBR) (Fig. 3) is generally a term used to define wastewater treatment processes where a perm-selective membrane, e.g., microfiltration or ultrafiltration, is integrated with a biological process - specifically a suspended growth bioreactor.4 Performance data for an MBR in terms of the composition of the influent and effluent is given in Table 2 for a case study at the Guggisberg Cheese plant in Millersburg, Ohio.5

Figure 3 - Membrane bioreactor.

Table 2 - Membrane bioreactor data from a case study (Guggisberg Cheese, Millersburg, Ohio).5

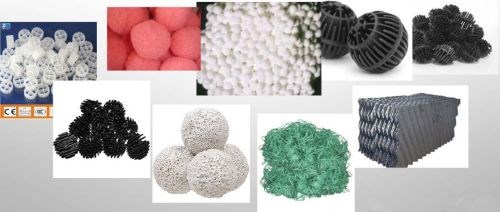

For fixed growth systems, as discussed here, there must be a place for the biomass to grow. There are as many media types as there are system sizes. Figure 4 shows just a few of the available varieties. Depending on what you want and need to remove, your design engineer will be able to recommend the right media aid for your bio system.

Figure 4 - Examples of media available for biological wastewater treatment.

Bacteria: The types of bacteria typically involved in biological wastewater treatment are shown in Fig. 5.

Figure 5 - Types of bacteria typically involved in biological wastewater treatment: (L-R) daphnia; stalked ciliates; filamentous; tardigrades.

Daphnia, or water fleas, swim in a jerky, hopping motion like a flea. A carapace (shell) covers most of its body. The carapace is hinged on one side. The other side is open to allow the water flea’s legs to move through the water to collect food and to swim.

Stalked ciliates can be seen in single organism form or can grow in colonies. Each “head” in a colony of stalked ciliates is considered one organism.

The presence of some filamentous bacteria is beneficial in floc formation to a biomass. The filaments connect to each other and form a mesh that is crucial for floc formation. Filamentous bacteria serve as a base of the structure on which other bacteria can attach and form flocs which are important in flocculation and settling.

Tardigrades, often called water bears or moss piglets, are near-microscopic animals with long, plump bodies and scrunched-up heads. They have eight legs, and hands with four to eight claws on each. While strangely cute, these tiny animals are almost indestructible and can even survive in outer space.6

Industrial performance in real time

As shown on Fig. 6, under a microscope, a healthy mix of bacteria from an industrial trickling filter can be seen in the influent (L) and effluent (R). Between these two photos, TKN is reduced from 9.57 to less than 1 mg/L. Phosphorus is reduced from 12.7 to 0.154 mg/L, while the COD influent of 121 mg/L is not detected in the effluent.

Figure 6 - Industrial biological treatment in real time.

References

1. D.H.F. Liu and B.G. Liptak, Environmental Engineers Handbook, 2nd Ed., CRC Press, Taylor & Francis Group, Boca Raton, FL (1997).

2. U.S. EPA, Wastewater Technology Fact Sheet: Trickling Filters, EPA 832-F-00-014 (September 2000).

3. M.L. Gulhane, Private communication (2015).

4. The MBR Site, https://www.thembrsite.com/what-are-mbrs/ (last accessed 07-06-2019).

5. bioprocessH2O, http://www.bioprocessh2o.com/case-study-cheese-plant (last accessed 07-06-2019).

6. Sacramento Splash, Water Flea, https://www.sacsplash.org/critter/water-flea (last accessed 07-06-2019).

7. EBS Environmental, Stalked ciliates, https://www.ebsbiowizard.com/resources/micro-gallery/stalked-ciliates/ (last accessed 07-06-2019).

8. The Water Network, https://wtp-operators.thewaternetwork.com/article-FfV/filamentous-bacteria-problems-and-solutions-r94HLW1n20o4ygPMhB7D4A (last accessed 07-06-2019).

9. A. Bradford, Facts about Tardigrades, https://www.livescience.com/57985-tardigrade-facts.html (last accessed 07-06-2019).

About the author

Robin Deal has been with Hubbard-Hall for five years. Prior to that, she worked for a major industry as a wastewater operator, holding a physical/chemical wastewater license in the state of North Carolina. During her time at Hubbard-Hall, she has increased her knowledge of different types of wastewater treatment, compliance regulations and new technologies to help industrial users meet their discharge permit requirements. She spends her time in the Inman lab perfecting new technologies for industrial wastewater treatment.

Footnotes:

*Compiled by Dr. James H. Lindsay, Technical Editor - NASF

** Corresponding author

Robin Deal

Technical Field Service, Aquapure

Hubbard-Hall

1101 Compton Bridge Road

Inman, SC 29349

Phone: (317)-850-6971

E-mail: rdeal@hubbardhall.com

RELATED CONTENT

-

The Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

-

Coating Systems with the Best Long-Term Performance

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.

-

Calculating Oven Heat Load Capacity

Please explain how to calculate the heat load capacity of a paint baking oven, using aluminum alloy wheels as an example.