Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.

#asktheexpert #medical #basics

Q: What are some new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry?

A: All over the world, companies producing implants, surgical instruments, medical tubes, electromedical equipment, optical and dental equipment, medical fixtures and even companies producing prefabricated parts and moldings for the medical device industry must produce in accordance with quality systems such as ISO 13485 or FDA 21 CFR820.

Featured Content

In addition to stainless steel, titanium and plastics, aluminum is a common, popular material. One international manufacturer of medical aerosol cans we know relies on a two-component system in its manufacturing process, in which the deep-drawn aluminum cans are cleaned without residues. The cleaning system has been established for years, fulfills all regulatory requirements and helps the customer achieve his goals in terms of perfection and precision.

In questions such as passivation, many other customers use products that have low surface resistance (< 5000 µOhm per square inch) and high corrosion protection on unlaquered surfaces (> 336 h NSS), which means it is optimally usable for the special requirements in the medical device industry. It is also usable on magnesium parts.

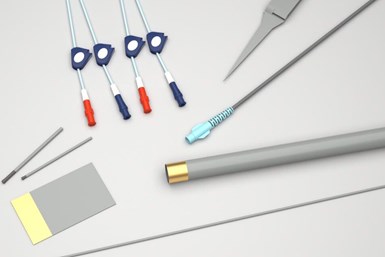

Functional coatings from Mueller Corp. include fluoropolymer coatings, including polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), fluorinated ethylene propylene (FEP) and perflouroalkoxy (PFA).

Photo Credit: Mueller Corp.

Another tough task is the integration of different substrate types in one cleaning line, which is a common scenario for many medium-sized companies. Validated results for bioburden, TOC-value and cytotoxicity are mandatory. Within the process, there are a lot of manufacturing steps with high claim on the surface. The process goal does not end in developing and delivering chemical specialties. It is important to consider the whole process chain as well as the individual needs of the producing company.

The list of possible applications shows that medical devices are not only the ones that can be bought in a pharmacy. Medical devices have their intended use in preventing, detecting and treating health care issues. They are tangible products made of metal, plastic or ceramic. The material basis of a medical device is called biomaterial. The qualifying criterion is biocompatibility. This includes not only the fact that the product must fulfill a certain functional similarity but also the requirement for a corresponding biological compatibility in the body.

Due to the materials used and the type of use, medical devices are subject to natural aging processes. Metal pretreatment and passivation processes support corrosion protection and lead to a measurable increase in product life. In addition, the manufacturing process and the purity requirements of the products require extensive cleaning processes. The task of industrial parts cleaning can be divided into four categories — pre- and intermediate cleaning enables the necessary cleanliness for the subsequent process steps. The precision and final cleaning ensure the cleanliness of the end product. Examples for decorative electroplating are eco-friendly Cr(VI)-free plating of stethoscopes or medical equipment. Examples for metal pretreatment are phosphating prior to a later coating; the passivation of a surface to prevent corrosion; a pickling to remove a small irregular surface layer; or anodization of aluminum.

The requirements regarding process stability can’t be answered in general. Each task requires an individual solution that takes into account the following criteria:

- Material combination (metals, plastics, ceramics and composites)

- Component geometry (size, weight and surface texture)

- Processing status and type (process parameter and disorder)

- Type and degree of pollution (inorganic and organic)

- Required properties (cleanliness and surface texture)

The most important objectives are the achievement of the required cleanliness, observance of legal compliance, orientation toward environmental compatibility and consideration of an economic process chain. However, this can only be achieved by taking into account the whole process. Process chemicals for industrial parts cleaning, metal pretreatment and electroplating must be able to clean the surface without residues and provide suitable corrosion protection. To ensure biocompatibility, the integration of rinsing steps is a must. The requirements after ISO 10993-5 are crucial to ensure biocompatibility. Nickel leaching is a big issue in electroplating, which we can pass with a solution without Cr(VI). Water-based chemical specialties are necessary for ultrafine cleaning. With support by ultrasound or spray applications, even with complicated geometries such as blind holes or smallest capillaries, the purity requirements can be reliably met.

Maximilian Kessler is in business development medical for SurTec. Visit SurTec.com.

Maximilian Kessler

RELATED CONTENT

-

Solving Unmet Needs of the Medical Device Industry

Pioneer Metal Finishing's Medical Center of Excellence has expanded the company's capacity to serve the critical medical device industry. With ISO 13485 certification in hand, the company is now a key driver in medical innovations.

-

Electroplating for Medical Devices

Brittany McKinney of Pavco Inc. discusses the benefits of electroplating for medical devices.

-

Glass Bead Blasting as Plating Pretreatment

What are the best practices for using blasting in preparation for plating? Angelo Magrone of Bales Metal Surface Solutions discusses the ins and outs of glass bead blasting.