Climbing the Nadcap Ladder for Certification

The Nadcap program is recognized as the premier accreditation program for aerospace and defense contractor supplier accreditation. With this accreditation, an anodizer can effectively access the supplier world of the aerospace and defense industries. We’ll lay out a road map for accreditation that is logical and achievable for someone committed to the excellence required to get to the end goal.

#military #education #aerospace

The Nadcap program is recognized as the premier accreditation program for aerospace and defense contractor supplier accreditation. With this accreditation, an anodizer can effectively access the supplier world of the aerospace and defense industries.

But the rigors of achieving Nadcap accreditation require dedication of resources, including time, money and psychological energy. We’ll lay out a road map for accreditation that is logical and achievable for someone committed to the excellence required to get to the end goal.

Accreditation requires a complete understanding of the AC7108D checklist, which is the bible of suppliers, auditors and chemical processing staff engineers at the Performance Review Institute (PRI), and the task group of primes and suppliers who administer the checklist.

Step 1

Your company must have an acceptable quality system in place or verifiable at your initial audit. This system is administered by the PRI, which acts as registrar for the system.

Usually the architecture of a “quality system” has several tiers that support the complete process control. The first tier is the quality manual (AC7004 or AS9100). It serves as your mission statement or “statement of core philosophy.” Below this core document is the procedures manual. The third tier should be specific work instructions which describe in detail how each procedure is actually performed. The fourth tier should be the forms that verify compliance with any procedures or work instructions requiring sign-off or verification of compliance with the work instructions, procedure or logs used to verify data.

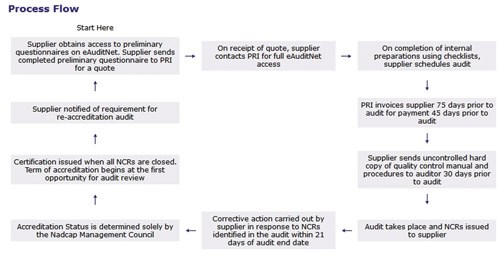

The AC7108D checklist uses the word “procedure” nearly 100 times, which should alert you to the need to have robust, revision-controlled procedures in every phase of your operations. Accreditation is difficult because Nadcap imposes plant-wide process control of everything happening in your plant through the checklist. But before commencing on the checklist journey, the author recommends registering with PRI. With full access to the eAuditnet website, one can access a wealth of resources.

Print out copies of the AC7108D checklist for your Nadcap team. Bring people into the process from all parts or your organization. Involve employees early and thoroughly. Don’t make the mistake of allowing people to regard the Nadcap audit as something residing in the domain of the quality department and not the concern of others.

Step 2

Section 2 of the checklist, “Instructions to Supplier to be Audited,” imposes a requirement that the supplier conduct a self-audit. While this is described as a critical first step, the supplier and his Nadcap team need to have studied the checklist and need to understand the myriad requirements before conducting the self-audit. Do the self-audit honestly and with a critical eye to whether you can answer “yes” to the checklist questions. Your auditor is going to dig in to areas of doubt. The rest of section 2 is self-explanatory, but do not ignore anything.

Step 3

Section 3 of the checklist focuses on the “General Quality System” and covers everything from process integrity through shipping and receiving to internal quality audits. It begins with questions about process integrity and immediately incorporates Appendix A by reference. Be sure to study Appendix A and its requirements for continuous improvement as managed by a “Control Plan.” The view is that if the supplier is not improving, then the opposite is probably taking place.

The subsections of Section 3 cover much of what goes on in the chemical processing plant—the physical activity that is subject to “procedures” and “process control.” You will want to create systems of procedures and forms that give your company control and verification of compliance with all of these sections.

Finally, Section 3 addresses internal quality audits. Essentially, we come full circle in Sections 2 and 3 concerning the importance of internal audits/self-audits. Effective self-audits will identify objective evidence to show compliance with a checklist question or will honestly identify a shortcoming that needs to be corrected.

Step 4

Section 4 of the AC7108/D checklist deals with periodic testing, lot testing and solution analysis. These disciplines, often set out in industry specifications, establish methods to measure the results of a process and control the chemistry used in the process.

Step 5

Section 5 deals with process equipment control and maintenance. There are several sections which may not apply and can be marked NA, depending on what your processes are. Be sure to check closely.

After you have completed your journey through the first five sections of the checklist, have a thorough understanding of the requirements and have achieved compliance with the requirements of these sections, turn your attention to job audits. Download “The Chemical Processing Auditor’s Handbook” and review it to get an understanding of the manner and method of the Nadcap auditor.

Step 6

Section 6 is the part of the checklist auditors use to determine compliance with specifications and the checklist when processing jobs. This is where the rubber meets the road. Perform your job audits using the Section 6 form, but also use the remainder of the checklist. At the end of the job audit, verify compliance with specifications completely—all elements of the specification.

When you have findings, which you should, generate corrective actions for the findings. This allows for documentation of what has been done through the appropriate use of continuous improvement methodologies. Be sure to follow up on the corrective actions to be sure they were effective and retain evidence of having done them.

When you have your real audit, don’t be surprised when there are findings, and don’t engage in arguments with the auditor. The auditors are trained to be objective and to look for objective evidence upon which they can answer “yes” to the checklist. If the evidence is inadequate (existence, compliance, adequacy) then the answer will be “no.” Auditors see black and white.

After the audit report is filed, you will have a chance to respond to the findings and communicate with the staff engineer assigned to you.

If you wish to access the aerospace finishing business, engage Nadcap fully; it will improve your company and open new avenues of business.

William Corcoran is a lead auditor for Nadcap. He can be reached at Bill@LTMTLS.com. You can get more information about Nadcap at pri-network.org/Nadcap.

RELATED CONTENT

-

Understanding Corrosion and Salt Spray

How it’s produced, NSS testing and how to get the best results possible.

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

Overview: Aerospace Anodize Finishes

The following anodizing process overviews are provided as a means of introduction to aerospace anodizing