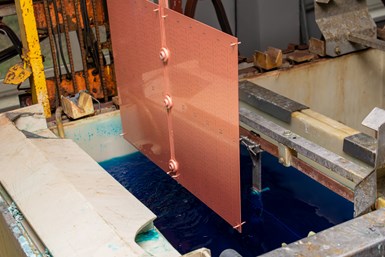

Copper Plating on Aluminum and Aluminum Alloys

How can I plate copper on aluminum?

#basics

Q. How can I plate copper on aluminum?

A. A typical process for plating copper on aluminum is:

- Degrease.

- Soak clean.

- Thoroughly rinse.

- Dip in a 50 percent nitric acid solution. Depending on the aluminum alloy, sodium bifluoride, sulfuric acid or chromic acid may have to be used in conjunction with nitric acid.

- Thoroughly rinse.

- Dip in a zincate bath for 1 minute. (Proprietary zincate solutions are best.)

- Strip the zinc coating using 50 percent nitric acid

- Rinse thoroughly.

- Dip in the zincate solution again.*

- Rinse thoroughly.

- Apply a copper strike using a cyanide or non-cyanide alkaline strike bath.

- Rinse thoroughly.

- Plate in a copper plating bath.

* Double zincate is always the recommended procedure for getting good adhesion to aluminum-based materials.

You can find many more details for this process by searching PFOnline.com for “plating on aluminum.” This search also will provide information for plating other metals on aluminum as well.

RELATED CONTENT

-

Aluminum Surface Finishing Corrosion Causes and Troubleshooting

In this paper, a review of several process solutions, examining coolants, solvent cleaning, alkaline clean/etch and deoxidizing/desmutting, listing intended and unintended chemical reactions along with possible mechanisms that would favor corrosion formation.

-

What is Electrocoating?

E-coat can produce uniform finishes with excellent coverage and outstanding corrosion resistance.

-

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.