Dealing With Dirt

New technologies improve E-coat quality and productivity

An electrocoat paint supplier's goal for automotive applications is to produce materials that provide good corrosion, adhesion and surface leveling characteristics.

The coating system supplier's goal for automotive OEMs is to provide equipment that will properly apply those coatings. In the past, equipment suppliers have focused on proper temperature and chemical control and good coverage. But increasing emphasis on reducing manufacturing costs has brought a focus on dirt control in the pretreatment/electrocoating system.

Featured Content

Numerous technologies have been developed for automotive E-coat systems with dirt reduction in mind. Many of the same technologies can also be applied to non-automotive systems.

Dirt Sources

A vehicle traveling from an automotive body shop to the next stage of production typically carries with it two major types of dirt contamination: oil and weld spatter.

Oil—typically left over from the body stamping process—is a contaminant that in most cases can be removed in the first three to four stages of the pretreatment system, which use a combination of dips and sprays with heated degreasing fluid to flood all exterior surfaces and interior cavities of the body.

The oil is suspended in the degreasing fluid and eventually removed by pumping the fluid through oil separators. These techniques are generally very effective as long as chemical concentrations, temperatures, and system maintenance are kept up.

Weld spatter is essentially a little droplet of molten material that is generated at or near the welding arc during body fabrication. Droplets can range in size from 70-200 µm in diameter.

As long as steel car bodies are welded, there will inevitably be weld spatter produced. There are really no known ways to capture the spatter so that it does not contaminate the vehicle in the body shop, leaving the paint shop to deal with this contamination.

Weld spatter is the hardest type of dirt to eliminate, and if not properly removed it can affect vehicle paint quality all the way through to the final clearcoat. The good news is that the spatter is metallic and therefore can be removed from a fluid relatively easily using bag filters, cyclones and magnets. The trick is getting the spatter to the bag filters, cyclones and magnets.

Spatter on exterior vehicle surfaces is relatively easy to rinse off. More difficult to remove is spatter on the inside of a vehicle, which has a multitude of cavities, creases, ledges, ridges, etc. that can capture the spatter and make it difficult to remove.

Weld spatter typically doesn't float, so removing it from an interior cavity requires high turbulence and good drainage from the vehicle. Otherwise, the spatter will be moved around but will never completely leave the vehicle.

Up to 20 g of spatter can be brought into the pretreatment system on a single vehicle. This may not seem like much, but one 50-mg spatter ball embedded in the electrocoat finish on a vehicle hood can create a defect visible from 5 ft away.

Pretreatment Stage 1

The first pretreatment stage a vehicle body sees in the paint shop is typically a deluge. A high flow rate of water (2,000 gpm) is essentially dumped into the body interior to try to stir up and flush out contaminants.

But removing weld spatter and dirt is not as simple as just dumping water in. There are many factors involved that determine the effectiveness of the rinsing.

One of the biggest appears to be the angle of the body when applying the deluge. Applying the deluge on a body that is essentially in road position (horizontal) will stir up a tremendous amount of dirt but will actually remove very little.

Every vehicle body has a different set of drain areas, cavities and so on, so it is difficult to make a broad statement and come up with one set of body angle/flow rate/nozzle configurations for drainage. However, a steep, nose-down angle of the body in the deluge stages appears to be the best configuration for most vehicle types and has been proven effective in both testing and actual production experience.

Deluge systems often include a cyclone separator, a very effective tool to remove weld spatter from the rinsing fluid. In this system, the deluge water is filtered in the tank. A separate flow stream is drawn off the tank through the separator. When the separator system is not running, most dirt will settle to the bottom of the tank. A drain valve allows system operators to draw off bottom dirt.

The cyclone is a closed vessel designed to convert incoming liquid velocity into rotary motion. It does this by directing inflow tangentially near the top of a vertical cylinder. This spins the entire contents of the cylinder, creating centrifugal force in the liquid. Heavy components (weld spatter and other contaminants) move outward toward the wall of the cylinder, where they agglomerate and spiral down the wall to the outlet at the bottom of the vessel. Light components (clean fluid) move toward the axis of the hydrocyclone and up toward the outlet at the top of the vessel.

Pretreatment Stages 2-12

Even with a highly effective deluge stage, several grams of weld spatter can still get through to subsequent stages. It is important to maximize removal of this spatter before the electrocoating process. Testing has determined that an indexing high-pressure spray tree is a very effective new method for enhancing the rinsing system. It is placed at the end of the pretreatment system, typically between Stages 11 and 12.

Most rinsing sprays in an automotive pretreatment line generate 20-30 psi of pressure at the spray nozzle. Systems have been installed with indexing high-pressure spray trees that produce anywhere from 300-650 psi of pressure at the nozzle. Such spray trees move up and down to follow the body contours and maintain the optimal distance between nozzles and body surface. They typically use approximately 50 gpm of deionized (DI) water.

Tests have been run to examine the effects of such high-pressure water spray on the crystalline structure of the phosphate coating produced in previous pretreatment stages. Results were satisfactory, and properly set up high-pressure indexing spray systems will leave 0.05 g or less of dirt on the vehicle after final pretreatment.

Regardless of operating pressure and indexing capability, existing pretreatment systems can be checked for their operating "I" factor, which is a patent-applied-for measure of dirt removal performance developed by TKS. "I" factor is determined by the following equation:

I factor = discharge pressure x nozzle angles x distance between nozzle and body surface x water volume. Nozzle angles and the distance between nozzle and body surface would be considered fixed values. Discharge pressure and water volume are the variables, with higher amounts considered better. Thus, high I factors are considered good for rinsing and dirt removal.

Nozzle angles and the distance between nozzle and body surface would be considered fixed values. Discharge pressure and water volume are the variables, with higher amounts considered better. Thus, high I factors are considered good for rinsing and dirt removal.

e-coat Paint Tank Counterflow

Despite efforts to remove it, some weld spatter will inevitably travel all the way through the pretreatment system and will end up rinsing out in the E-coat tank. Many E-coat systems built in the past allow particles suspended in the tank to stay in suspension for days or weeks. These particles will eventually end up on the E-coat surface, and will stay there until they are baked in and then need to be sanded out.

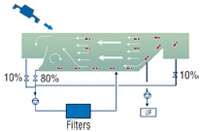

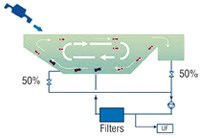

Particles are able to stay in suspension due to a flaw in circulation of the E-coat paint in the tank. Many systems are designed with eductor flow that generates a continuous circular flow in the tank. Dirt particles that get caught up in this flow can stay suspended indefinitely.

A patented E-coat counterflow system is designed to minimize circulating eddies, allowing dirt particles to be collected and filtered out within 1-2 turnovers of the tank cycle. With this setup, weirs at both ends of the E-coat tank reduce or eliminate foam and dirt flotation. Equal laminar paint flow from rear to front of the tank is the goal in eductor design.

Tank turnover rates would be approximately the same between conventional (4 turnovers/hr) and counterflow systems (3.7 turnovers/hr). Surface flow rates for the counterflow system, however, would be almost double those of a conventional system (33 fpm versus 19.7 fpm). Higher surface flow rates ensure that bubbles and foam will not have a chance to collect on body surfaces and create quality problems.

It has been demonstrated that dirt entering a counterflow E-coat system can be effectively removed within 40 sec. Compare that to a poorly designed conventional system, where dirt can be suspended in the tank indefinitely.

Transfer to Curing

As part of an overall effort to minimize system dirt during E-coating, several new technologies have been added prior to the curing oven.

For example, it is fairly common for vehicles to continue draining fluid for several minutes after the final E-coat rinse stage. This fluid is mostly pure water; however, some E-coat paint solids are still suspended in the fluid. Over time, this fluid drains onto the floor of the curing oven. The solids are baked onto the oven floor and can cause dirt problems as they flake off the floor and become airborne.

A simple, inexpensive improvement to this situation is to use an up and down movement on the conveyor in the tunnel exiting the final E-coat rinse. This will cause a good portion of the remaining rinse fluid to drain out of the vehicle bottom.

Several automakers have implemented a further step by installing a preheat oven to dry vehicle bodies before they enter the curing oven. This typically exposes the vehicle to 8 min of 215°F air, which dries it before entering the curing oven. The combination of these two practices dramatically slows the amount of drainage seen inside the curing oven.

For information on TKS Industrial, please visit tksindustrial.com

RELATED CONTENT

-

The Hull Cell: Key to Better Electroplating - Part I

How to use it for planning, preventive maintenance and troubleshooting.

-

VDA 19 and its Impact on European Manufacturing and Cleaning

The German Association of the Automotive Industry’s VDA Volume 19 is the first comprehensive standardization document for characterizing the cleanliness of products within the automotive industry’s quality chain.

-

Powder Coat MDF for an Enviable Finished Product

Cabinet maker says powder coating on wood offers more benefits.