It’s been said that the only thing constant is change, yet some also say that finishing systems have not changed much over the last 30 years. When you really think about it, however, there have been many developments in finishing that may not have been imagined in the not-so-distant past.

These developments include, in alphabetical order: antimicrobial coatings, auto-deposition, bio-based waterborne polyurethanes, electrocoats, environmentally friendly encapsulation technologies, infrared curing, low-VOC paint, low-temperature-cure powders, nanotechnology, phosphate-free pretreatments, robotics, self-healing coatings, two-coat powders, ultraviolet cure, zinc phosphate and zirconium.

Featured Content

This list isn’t meant to be all inclusive; it just illustrates that change is occurring. So the question becomes: How do you design a finishing system with the most up-to-date technology, that is ready to adapt to future improvements and that is not overbuilt for future production rates, and get the most for your dollar?

Basic Design Considerations

Here are some basic questions to consider first if you are attempting to design a finishing system that will last for the next 20 to perhaps even 50 years:

- How many parts will need to be painted per hour, now and 10 to 15 years from now?

- Are there likely to be vast advancements in any aspect of what is being done currently, such as new pretreatment technology, new coating technology or new curing technology?

- Will the current processes remain the same? Will continuous improvements allow for new part designs that no longer require masking? Powder instead of liquid? Two-coat powder?

- Should cart or fork truck transfer be eliminated by using the same overhead conveyor to deliver parts to the paint system from welding and/or then to shipping?

Perhaps answering these questions will lead you to consider systems that are expandable for future growth, flexible to incorporate new technologies, adaptable for changes in processes and able to convey to point of use (from fabrication to finishing to shipping).

For the most part, systems start with deciding on the fourth consideration: the most appropriate method of conveying parts. The goals for all conveyors are usually:

- Move parts efficiently between and through processes.

- Minimize wasted movement and damage to parts, as well as risk of injury.

- Move parts to and from point-of-use stations.

- Relay system data and sometimes process and part data to operators and managers, usually through integrated computer controls, and sometimes connection to existing enterprise resource planning (ERP) systems and functions.

- Facilitate the implementation of an accurate part finishing recipe, or recipes if there are variations.

Three Main Types of Conveyor Systems

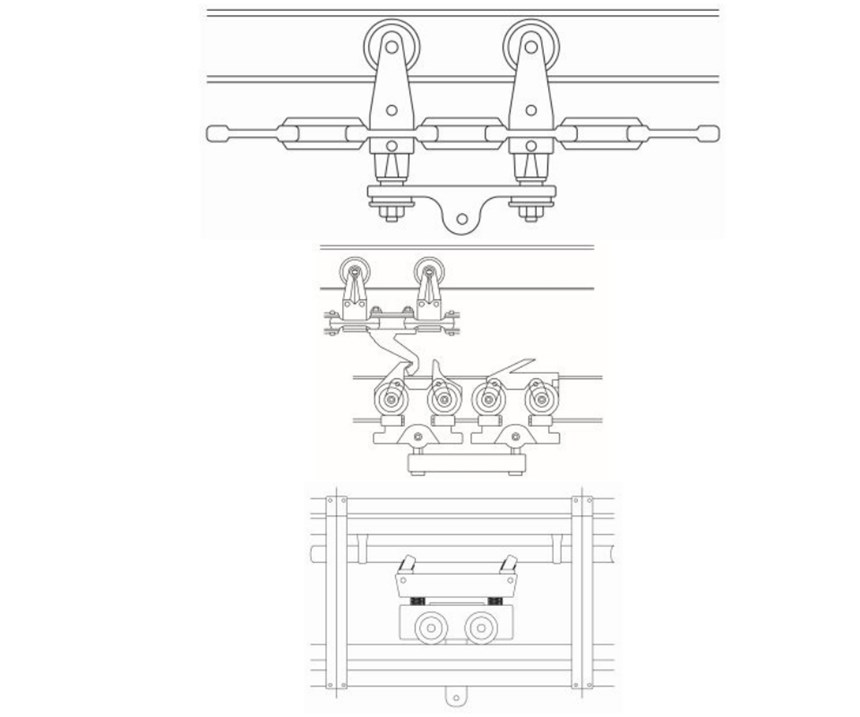

In automated powder finishing systems, there are three primary types of conveyors; all three are usually installed overhead, although each can also be installed at other elevations, depending on the process. These three are monorail, power and free, and friction-driven conveyors. Each has its advantages and disadvantages; no conveyor type is perfect for every application.

Monorail conveyors. The load-carrying and drive functions of monorail systems are combined in one element: an “endless chain.” These systems are typically the least expensive automated option, and they are known for being extremely durable. The chain is typically guided by a rail system based on I-beams or enclosed tracks. A “caterpillar drive” or sprocket drives the chain from the drive unit, and a take-up unit ensures the chain is pulled tight as it leaves the drive unit to complete its circuit. Monorail conveyors typically move at a slow pace and continuously. Stopping part of the line for any unscheduled process or other reason stops the entire line upstream and downstream as well. Changing the system to move faster or slower–for example, if you need to shorten the cure time for a new paint—means all other processes on the line will occur faster as well, from loading to pretreatment to cool-off.

Power and free conveyors. P&F conveyors also move continuously on a chain-driven system and, like monorails, are extremely durable, but they can be much costlier. Their biggest advantage is that items can be decoupled from the chain to allow for starts and stops. This is especially useful for moving heavy/hard-to-load items, long items or items that require in-process masking; quality control stops; or moving items that need to spur off to optional processes.

With a P&F system. the “power chain” runs in a “power track” that continuously moves load bars hanging from free trolleys (connected to the power chain) through the system. The front and rear trolleys are separated by a load bar that is in place to keep the other load bars from crashing into each other and to provide better capacity. Flippers on the trolleys transfer power from the chain to the trolley via “driving dogs,” propelling the trolleys forward on the system. The rear trolley follows the front trolley (connected via load bar). Just like trains, P&F conveyors have tracks and switches and operate similarly; they can direct the trolleys to the appropriate tracks within a system (when there are multiple paint booths for a variety of product colors, for example).

Friction-driven conveyors. In friction-driven systems, trolleys are propelled by a stainless-steel spinning tube and drive belt (circling the tube), which creates the spinning motion. This type of conveyor can provide ultimate flexibility and efficiency, allowing carriers to move the trolleys both forward and in reverse, and to stop in any zone or within any process without affecting the rest of the line. Each section or zone is independently controlled by its own variable-frequency drive and drive belt.

Friction-driven conveyors boast immediate system response to changing processes or destinations through the use of smart controls and recipe systems. These systems can be relatively expensive, but they are competitive with multiple-chain power and free systems.

A friction-driven system can allow for a reduced footprint; offers the ability to index (start and stop) during loading and unloading; and enables masking, shot, wash, paint, cure and inspection stations. Since all the sections are interlocked using programmable logic controllers and supervisory computer programming control, these systems also can be more interactive with ERP and lean systems.

Friction-driven systems also typically feature part recipe control, multi-lane process equipment and bolted-together modular construction. These features allow for the ability to scale the system by adding additional tracks or processes as a shop’s needs change. For example, with these systems, the conveyor can extend the load process into fabrication, or unload into assembly or shipping areas. Friction-drive systems can also be moved more easily, since, unlike chain systems, they are typically bolted rather than welded together. Friction-driven systems can also incorporate vertical lifts for extremely heavy parts or shuttles for especially long parts in order to move the parts laterally, eliminating the need for wide-radius turns.

Choose a Plan for the Next 10 Years

Choosing the right conveyor for today can be as simple as determining your business plan for the next 10 years (or longer). Are you planning to grow and diversify your product offering, or plateau where you are now? Get a feel for your rate of change. Ultimately, your business plan should play a big part in choosing the right conveyor.

If you are in a business that needs flexibility or otherwise require flexible processes, you should consider conveyor options that offer the type of flexibility you need, within your budgetary constraints. Ultimately, that’s the only thing constant.

John Claman is a sales representative and marketing supervisor at IntelliFinishing. Visit intellifinishing.com.

RELATED CONTENT

-

Preparation of Stainless Steel for Powder Coating

Should type 316 stainless steel castings be sandblasted before powder coating, or can they be chemically etched? Should the parts be pre-heated in an oven before coating?

-

The Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

-

Anodizing Vs. Powder Coat

I am an engineer on a large yacht build project and urgently need information and advice on choosing a finish for the aluminum deck plates in the engine room.