Electroless Nickel Baths Get Simpler

How Michigan’s Classic Plating switched to a one-step process to get better brightness.

If you want to send plating shop owners or managers into a frenzy, ask them to swap out their existing chemical baths for something that is new to the market. The reaction you will get may be the equivalent of asking a Coke drinker to try a Pepsi, or convincing a Bud man to chug a Heineken. It might even get you a death stare.

Classic Plating co-owner Mike Morgan had no qualms, however, when Surface Technology Inc. President Michael Feldstein asked him to try his company’s new electroless nickel (EN) product, One-Plate, a single-component bath makeup and replenishment solution.

Featured Content

“No reservations whatsoever,” Morgan says. “We put it right into a 450-gallon tank. We’ve dealt with Michael and his company for our EN chemistries, and we know he uses the product, too.”

Morgan’s father, John, started Classic Plating in 1985 with Mike’s older brother, Ken, but Mike and his brother Steve are currently the co-owners and have been running it since 1989 with their sister, Sue Barbret, the company president who also manages the office. The Redford, Michigan, company has a total of seven employees, including the ownership family.

Feldstein not only makes and sells his own chemistries, but his New Jersey company is also a job shop that has been in business since 1973, when it was founded by his father, Dr. Nathan Feldstein, a Products Finishing Hall of Fame member. For the last two years, Surface Technology has earned a Products Finishing Top Shops status, too. Last year, the shop moved into a new facility and increased capacity by 20 times, with further room to grow.

All of these factors were enough for the Morgans to switch to One-Plate, a single-Q component for both the makeup and replenishment of EN baths that Feldstein says overcomes the many shortcomings of the decades-old practice of using three or four different solutions.

Optimal Concentrations

“It keeps all the ingredients in optimal concentrations,” Feldstein says. “More importantly, it avoids mistakes and contamination, and ensures consistently high-quality plating.”

Classic Plating has been working with Surface Technology for several years, so Morgan wasn’t concerned when Feldstein asked him to test out the new product.

“We really put it through the ringer,” Morgan says. “Surface Technology wanted us to give them honest feedback on how well it performed, and when we finished running the first series of tests, we saw that it did stand up quite well. We were pleased.”

Classic Plating focuses on EN and tin plating services, and its full line of services includes EN and EN polytetrafluoroethylene (PTFE) co-deposits, bright nickel, bright acid tin, and satin tri-chrome.

The EN PTFE is a composite, high-phosphorous process designed to deposit a uniform, nickel-phosphorous-composite alloy with ultra-fine PTFE particles. According to Morgan, it offers excellent corrosion resistance, and very good lubricity and release properties. He says it can increase mold life and improve release because it has a very low coefficient of friction, especially in applications where sliding wear is present.

Prior to switching to One-Plate, Classic Plating was running an additive bath, supplying its own nickel sulfate and sodium hypophosphite, and buying its replenishing additive from Surface Technology. “We used to ‘home brew’ quite a bit,” Morgan says. This is the type of system most EN shops have followed for decades.

Less Chance of Human Error

Surface Technology has pushed the One-Plate concept as a simpler way to manage EN baths, with less chance of human error.

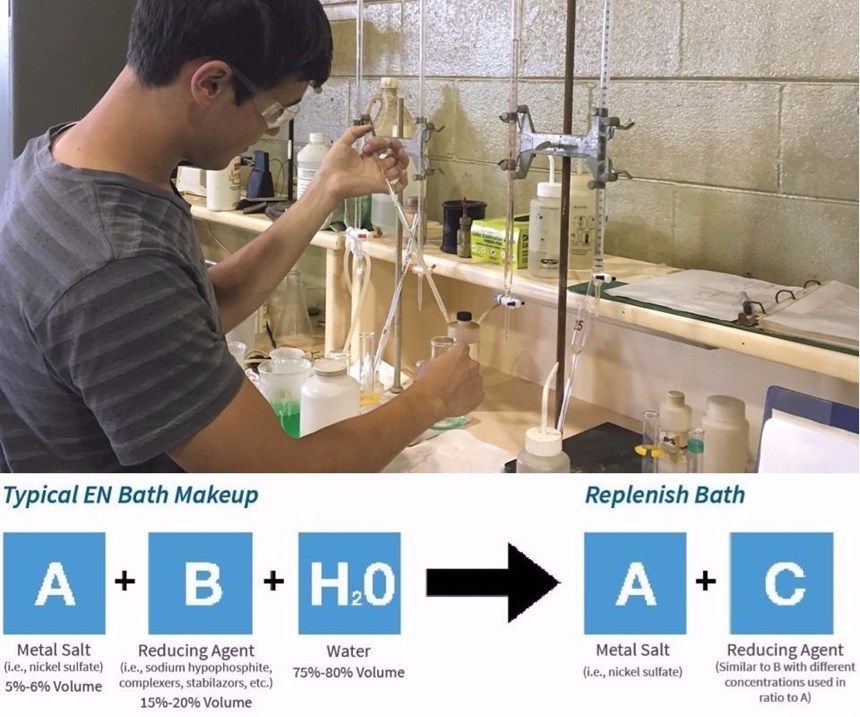

“The most widely used method to make up and replenish EN baths is to use three solutions, commonly designated as A, B and C,” says Jijeesh Thottathil, the company’s EN solutions manager. “The A solution contains the metal salt, for example, nickel sulfate, and may contain other ingredients, and it accounts for five to six percent of the volume of the plating bath.”

He says the B solution contains the reducing agent, such as sodium hypophosphite, and other functional ingredients like stabilizers, brighteners, pH buffers, chelators, complexing agents, accelerators and stabilizers. It accounts for 15 to 20 percent of the volume of the plating bath.

“The balance is typically about 80 percent of the volume of the plating bath and is made up of water, plus the possibility of an acid or base to adjust the pH of the EN bath before it is used for plating,” he says.

All that mixing and measuring can often lead to imbalances, especially when the EN bath needs to be replenished with the A solution and a C solution, Feldstein says. This led Surface Technology—which as a plating shop itself understands the practical aspects of plating, not just the science—to come up with the idea for One-Plate.

“Some shops in the plating industry have offered and used systems where the bath can be made up of one single component instead of two, three or more,” he says. “But in none of these systems is it possible to replenish that same bath with the exact same makeup solution for ongoing maintenance of the bath over the bath’s life, while providing proper bath stability and plating quality.”

Outstanding Brightness

And that is what Feldstein says One-Plate does: provides as consistent a result as EN baths made and replenished with multiple solutions. But it wasn’t the ease of use that sold Morgan on the product; it was the visual result.

“I loved the one component aspect of it, but what really hooked me after we ran it was the brightness that was maintained, and actually improved, over the life of the bath,” he says. “Secondly, the rate of the bath was always consistently high. A lot of baths drop off, and the rate slows down quite a bit, but this bath seems to keep the rate pretty steady all the way through the life of the bath.”

From an operational standpoint, the Classic Plating team also likes that fact that it doesn’t have to track the additions as much.

“The biggest difference is the additions,” Morgan says. “We now have the one component to track and add, which makes things so much simpler. We stopped monitoring how much nickel we have or how much hypo we have. We don’t think of A, B or C any longer, and that truly is a time-saver.”

Even though Classic Plating is located in the heart of the automotive industry, it has shied away from that sector and has instead focused on tool and die, injection molding, military, aerospace and medical industries.

RoHS-Compliant Baths

Working in those industries means Classic Plating must have chemistries that are compliant with the Restriction of Hazardous Substances (RoHS) directive from the European Union. This directive restricts the use of specific hazardous materials found in electrical and electronic products.

Fortunately, Surface Technology developed the One-Plate medium phosphorous bath to be RoHS-compliant and says it has other versions in the works, such as low- and high-phosphorous, nickel-boron, and composites including diamond, PTFE, boron nitride and others.

Classic Plating has been happy with its switch to the One-Plate system. “It truly runs beautifully,” Morgan says.

The shop runs a large EN line with a 1,000-gallon tank. It also includes the 450-gallon 1001-Q tank, which is RoHs-compliant, and a 450-gallon EN PTFE tank.

“We get a lot out of that particular line,” Morgan says. “We also have a smaller EN line, which works well when we are either super busy and need the capacity, or when we are slower and we can just fire up the smaller line.”

Big Labor Savings

The complexity of running EN lines, in which the parameters are fairly tight and danger lurks when baths get out of spec, is one reason Classic Plating welcomed the simpler method of using the One-Plate products.

“A shop that doesn’t have a lot of analytic experience with baths would probably really help themselves with the One-Plate process,” Morgan says. “I think because it is easier to use, a lot of plating shops that haven’t done EN before could now probably use this application.”

While the mil-per-square-foot cost of One-Plate is essentially the same as traditional EN systems, Morgan says there is additional labor savings. He says it takes three times as long to make additions to the bath using the old way, and there is an improved quality of the deposits as the bath ages, which is paramount for what he wants to provide his customers.

In addition, Feldstein says using One-Plate saves the plating shop on the cost of shipping, because the one-step system has less volume than traditional three-component, A-B-C systems. It also is easier and more economical to inventory only one solution, with no spare amounts left in drums.

“One-Plate really is a plug-and-play product, and we are very happy doing it that way,” Morgan says.

For information on Classic Plating, visit classicplating.com. For information on Surface Technology, visit surfacetechnology.com.

RELATED CONTENT

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

Stripping of Plated Finishes

The processes, chemicals and equipment, plus control and troubleshooting.

-

Smut and Desmutting

Question: I am new to this industry and have heard about smut and desmutting operations.