Electroless Nickel-plated Steel versus Stainless Steel: Case Studies

This paper highlights two case studies of manufacturers that have replaced, or done studies to replace, stainless steel with electroless nickel-plated mild steel. In both cases, cost savings could be realized while maintaining or improving product quality.

#research #surfin

by

Lloyd Ploof

Featured Content

Greer, South Carolina, USA

Editor’s Note: This paper is a peer-reviewed and edited version of a presentation delivered at NASF SUR/FIN 2014 in Cleveland, Ohio on June 9, 2014. A printable PDF version is available by clicking HERE.

ABSTRACT

This paper highlights two case studies of manufacturers that have replaced, or done studies to replace, stainless steel with electroless nickel-plated mild steel. In both cases, cost savings could be realized while maintaining or improving product quality. It is the hope of this author that the information included herein will allow or inspire metal finishers and manufacturers to consider such options to save costs, boost competitiveness and increase finishing sales.

Keywords: electroless nickel-plated steel, stainless steel

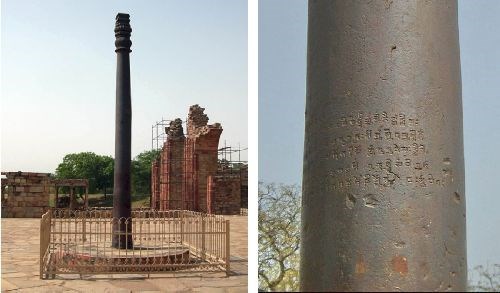

Corrosion resistant steels have been in existence for well over a thousand years. One of the earliest examples is the Iron Pillar of Delhi (Fig. 1). This Hindu monument was constructed around 400 A.D. from an iron-, and interestingly enough, phosphorus alloy. Its longevity and corrosion resistance are due to the formation of a phosphate film on the surface of the metal. After 1600 years in the open air, it has barely corroded, and the phosphate film has grown by just 1/20 of a millimeter.

There are many other instances of historic corrosion resistant steels, but commercial, large production practicality has come only in the last 100 years with the development of the electric arc furnace (EAF), in which most of today’s stainless steels are produced.

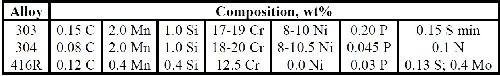

Most corrosion resistant, or stainless, steels today owe their stain and corrosion resistance to high levels of chromium and nickel in the alloy. There are over 150 grades of stainless steel available on the market today. These can be classified into five groups: austenitic, martensitic, ferritic, precipitation-hardened and duplex. This study only considers the austenitic alloys 303 and 304, and the martensitic alloy 416R.

Austenitic stainless steels (200 and 300 series) are generally more corrosion resistant than the martensitic stainless alloys, but as a rule, they cannot be hardened by heat treatment. Martensitic stainless steel alloys (400 series) can be hardened by heat treatment, but usually are not as corrosion resistant as the austenitic alloys. Composition comparisons are shown in Table 1.

Figure 1 - (a) Iron Pillar of Delhi, 1600 years old; (b) Close-up showing minimal corrosion.

Table 1 - Composition of stainless steels used in this work.

Drawbacks to using stainless steels in manufacturing include price, machinability, and hardenability. According to www.worldsteelprices.com, during April of 2014, the Global Composite Carbon Steel Price was $713/tonne, where the Global Composite Stainless Steel 304 Price was $2778/tonne. Stainless steel costs upwards of 3.8 times as much as carbon steel.

In terms of machinability, as a class, stainless steels are generally more difficult to machine than carbon or low-alloy steels because of their higher strength and higher work hardening rates. They require greater power and lower machine speed, while shortening tool life and sometimes leading to difficulty in obtaining a fine surface finish. However, it must be noted that wide variations exist in these characteristics among the different types of stainless steels.

Concerning hardenability, as was previously stated, austenitic stainless steels generally cannot be hardened by heat treatment. Because of these drawbacks, at least two manufacturers have either switched, or considered switching to, electroless nickel (EN)-plated mild steel. What follows are two case studies related to these manufacturers’ experience.

Case Study #1: Manufacturer of hydraulic load leveling systems

HWH Corporation is a manufacturer of load leveling systems for recreational vehicles (RVs) and campers, among other things. They are located in Moscow, Iowa and employ 300-400 people. The company was founded in 1967 and for the first 17 years of business they designed and manufactured machines and hydraulics for agricultural customers, including John Deere and Caterpillar. During those early years in the agricultural industry, they also discovered a niche for supplying hydraulic leveling systems to the RV industry (because the RV industry was currently borrowing agricultural equipment to meet their needs). HWH has since led the RV industry in hydraulic and air leveling technology. They've introduced countless novel hydraulic slide-out systems to the market and have brought many other hydraulic/air solutions to the RV market, ranging from hydraulic step systems to air suspension systems to saddle-rack systems, as shown in Fig. 2. Most of the hydraulic shafts were made from 303 and 304 stainless steel, and while performing well, they were very expensive to manufacture. Further, during the early and mid-2000s, stainless steel prices rose sharply, and correspondingly, the availability decreased dramatically. HWH began to look for alternatives and electroless nickel was one of them.

After many discussions with management and engineering staff at HWH, it was decided that for the initial testing, 1026 and 1018 steel tubing plated with 0.0015-in. thick high-phosphorus electroless nickel would be evaluated versus the stainless steel. Parts would also be baked for stress and hydrogen embrittlement relief. Some of these parts would be put into service right alongside the stainless steel shafts to see if there were any performance differences. Other parts would be left outside for extended periods to gauge the relative corrosion protection characteristics between the materials.

After months of successful testing, it was decided to replace the stainless with EN-plated 1026 mild steel on one series of the hydraulic load leveling jacks. A small EN line was installed and, after overcoming the learning curve of becoming platers, limited production began for one year. During this time, no EN-plated jacks came back from the field for failure.

The decision was then made to install a large line and change all the stainless jacks to EN-plated 1026 and 1018 steel. This took about a year to order, fabricate and install.

HWH now plates all their hydraulic jack shafts with 0.0015-in. high phosphorus electroless nickel. They use the bath to about five metal turnovers (MTO). At this point, they use this older bath to plate other system parts with EN that would not otherwise get plated, providing even more value to their customers. They coat hundreds of shafts and hundreds of other parts each day.

During the first full year of change from stainless to EN plated steel, the company’s savings were calculated to be over one million dollars.

Figure 2 - Products for recreational vehicles and campers: (a) Load leveling jack; (b) RV slide-out system.

Case Study #2: Firearms manufacturer

A major firearms manufacturer producing sporting rifles with stainless steel barrels and bolts also considered cost reduction strategies in order to help maintain or increase market position while still supplying their customers with outstanding value. They investigated the use of electroless nickel-plated steel in place of the 416R stainless alloy they were using on some extreme environment rifles. This manufacturer already had experience with the use of electroless nickel to coat gun parts for aesthetics, corrosion resistance, lubricity and wear. Satisfied that electroless nickel would meet the criteria for aesthetics, lubricity and wear, they needed to determine, for these specific parts, if electroless nickel would meet or exceed the corrosion performance of the 416R series stainless barrel and bolt, and the 304 series magazine.

One rifle barrel, bolt and bolt plug were fabricated from 1155 steel and plated with a duplex electroless nickel coating of 0.0003 in. of mid-phosphorus EN under 0.0002 in. of high phosphorus EN, for a total thickness of 0.0005 in. The components were assembled into a working gun with stock and fire control mechanism. One each of three different style magazine boxes were fabricated from 1010 steel and coated with 0.0002-0.0004 in. of high phosphorus EN. The magazine boxes were not assembled into guns.

These boxes were placed in a salt spray cabinet along with a 416R stainless steel extreme condition gun and the corresponding 304 stainless magazine boxes. Photos were taken and the guns were checked for functionality at 4, 45, and 93 hours of salt spray exposure. The results follow.

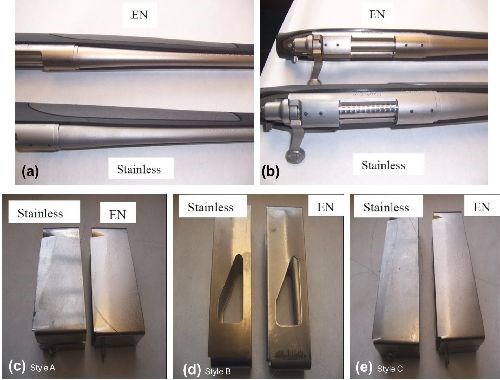

Specimens in the as-received condition

Figure 3 shows the gun parts is in the as-received condition, labeled as stainless steel or electroless nickel-plated. The barrels and receivers are shown in Figs. 3(a) and 3(b). The yellowish cast taken on by the electroless nickel finishes is merely a reflection of the surrounding area in the laboratory. Three different magazine box styles are shown in Figs. 3(c), 3(d) and 3(e).

Figure 3 - Specimens under study in the as-received condition: (a) barrels, (b) receivers, (c) magazine box style A, (d) magazine box style B and (e) magazine box style C. Both stainless and electroless nickel finishes are shown in each photo.

Specimens after 4 hours of salt spray

Figure 4 shows the test parts after 4 hours of salt spray, labeled as stainless steel or electroless nickel-plated. The first signs of corrosion are already apparent on the stainless steel barrel (Fig. 4a), as well as on the bolt head area of the stainless steel receiver (Fig. 4b). Mechanically, both actions were fully functioning. No corrosion was noted on the electroless nickel-plated receivers or bolts. Magazine box A (Fig. 4c) showed no rust on the stainless steel finish. Very slight rusting was noted on the shelf area of the electroless nickel-plated box. Boxes B and C (Figs. 4d and 4e, respectively) exhibited no corrosion.

Figure 4 - Corrosion test results after 4 hours of salt spray: (a) barrels, (b) receivers, (c) magazine box style A, (d) magazine box style B and (e) magazine box style C. Both stainless and electroless nickel finishes are shown in each photo.

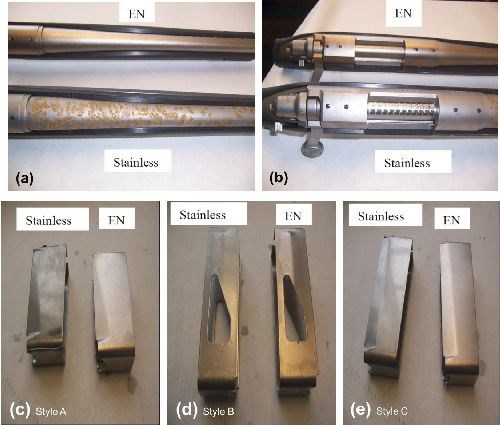

Specimens after 45 hours of salt spray

Figure 5 shows the test parts after 45 hours of salt spray, labeled as stainless steel or electroless nickel-plated. 100% red rust was observed on the stainless steel barrel (Fig. 5a), while there was no rust on the EN-plated barrel, except inside, where there was no plating. There was extensive rust on the bolt head of the stainless steel receiver (Fig. 5b), while there was no rust noted on the EN-plated receiver. However, both receivers exhibited corrosion from the steel scope mount screws, which were not stainless, nor were they plated. Mechanically, the stainless steel action was beginning to show resistance. No corrosion was noted on the electroless nickel-plated receivers or bolts. Magazine box A (Fig. 5c) showed no rust on the stainless steel finish and less than 1% rust on the electroless nickel-plated box. Box B (Fig. 5d) showed no rust on the stainless steel finish and less than 2% rust on the electroless nickel-plated box. Box C (Fig. 5e) exhibited no corrosion with either finish.

Figure 5 - Corrosion test results after 45 hours of salt spray: (a) barrels, (b) receivers, (c) magazine box style A, (d) magazine box style B and (e) magazine box style C. Both stainless (L) and electroless nickel (R) finishes are shown in each photo.

Specimens after 93 hours of salt spray (end of test)

Figure 6 shows the test parts at the end of the test, after 93 hours of salt spray, labeled as stainless steel or electroless nickel-plated. As at 45 hours, 100% red rust was observed on the stainless steel barrel (Fig. 6a), while there was no rust on the EN-plated barrel, except inside, where there was no plating. The bolt head of the stainless steel receiver was 100% rusted (Fig. 6b), with extensive rust on the bolt handle. There was no rust noted on the either receiver except that from the steel scope mount screws. Mechanically, the stainless steel action was completely non-functional, while the EN finish action was still fully functional. No corrosion was noted on the electroless nickel-plated receivers or bolts. Magazine box A (Fig. 6c) showed slight rusting on the stainless steel finish and about 2% rust on the electroless nickel-plated box. Box B (Fig. 6d) showed slight rusting on the stainless steel finish and 5-10% rust on the electroless nickel-plated box. Box C (Fig. 6e) showed slight rusting on the stainless steel finish and less than 1% rust on the electroless nickel-plated box.

Figure 6 - Corrosion test results after 93 hours of salt spray at the end of the test: (a) barrels, (b) receivers, (c) magazine box style A, (d) magazine box style B and (e) magazine box style C. Both stainless (L) and electroless nickel (R) finishes are shown in each photo.

The electroless nickel-plated 1155 steel gun significantly outperformed the 416R stainless steel gun in corrosion resistance as tested with neutral salt spray. The 416R stainless steel barrel began to show red rust within a few hours of being subjected to salt fog, where, at the end of the test at 93 hours, the EN-plated barrel exhibited no corrosion on the outside of the barrel where it was coated. On the inside of the barrels, where there was no EN coating, the barrels exhibited similar rusting conditions.

Oddly, the 416R stainless steel receiver performed as well as the EN-plated 1155 steel receiver. It was surmised that this was because the receiver was subjected to a different heat treat cycle than the barrel.

As far as the functionality of the firing mechanisms, the EN-plated gun continued to function, both in firing and safety, throughout the testing, whereas the stainless steel gun failed after approximately 70 hours of salt spray exposure.

The stainless steel magazine boxes, being made of the more corrosion resistant 304 stainless steel, outperformed the EN-plated magazine boxes, but not by the overwhelming margin that the EN-plated barrel outperformed the stainless steel barrel. It should be noted again that the EN thickness on the magazine boxes was minimal at 0.0002-0.0004 in. Further, it can be reasonably surmised that if the EN-plated magazine boxes had been coated to a higher thickness, they would have performed much more comparably to the 304 stainless boxes in this corrosion testing.

When cost savings were calculated, there would be a savings of over $17.00 per gun when using EN-plated steel instead of the 416R or 304 stainless steel. With nearly 11,000 stainless steel units produced each year, a cost savings of $187,000/annum would be realized, with improved corrosion resistance and increased functionality.

Conclusions

While it is obvious that replacing stainless steel with coated steel is not feasible in every instance, from the two case studies above, it can be seen that electroless nickel-plated steel may be able to replace stainless steel in certain applications. It is the challenge of the industrious metal finisher, or the visionary manufacturer to find new applications where this strategy might work and empirically determine its chances of success.

Note: All information contained herein is used with the permission of the respective companies.

Footnotes

*Corresponding author:

Lloyd Ploof

Metal Chem Inc.

29 Freedom Court

Greer, SC 29650

Phone: (864) 877-6175

E-mail: marc@metalchem-inc.com

RELATED CONTENT

-

Choosing and Troubleshooting Copper Electroplating Processes

Learn more on this inexpensive and highly efficient process.

-

Gold and Silver Plating Basics

An overview of precious metal electroplating processes.

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.