Evaluating Coating Options

Software facilitates direct cost comparisons

Liquid or powder? Spray to waste or reclaim? Is a system with fast color change capability the right choice? These are just a few of the many questions coaters often have when developing the most economical coating processes for themselves and their customers.

New software from Nordson Corporation, Industrial Coating Systems (Amherst, OH), can help users with the decisions mentioned above and more. The company’s nVision Tools lets users develop multiple interactive computer models for both powder and liquid coating lines to evaluate many options quickly and thoroughly and make decisions based on hard economic comparisons.

Featured Content

“The software lets users test the effect of any process variable on overall profitability,” explains Ken Kreeger of Nordson’s Industrial Coating & Automotive Systems division. “Detailed ‘what if’ scenarios allow for various input data so users can input what they know in the most convenient format to help them make educated decisions.”

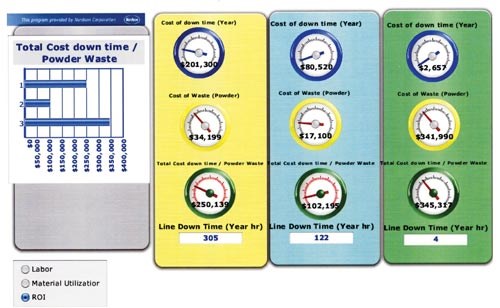

An example cited by Kreeger is the decision to reclaim versus using a spray-to-waste system in a powder coating operation. “Using this model, we can experiment with virtually any number of scenarios, changing such parameters as number of color changes per day, work days in a year, line burdened cost, number of guns, pounds of powder used per hour, transfer efficiency and powder cost per pound,” Kreeger says.

“Plant supervisors and operators may focus on factors such as transfer efficiency, but another key parameter, especially in plants where the value of goods sold is very high and the plant is operating at high capacity utilization, is lost production time,” Kreeger adds. “The value of lost production can rapidly tip the scale in favor of any approach that maximizes the productive ‘up time’ of the paint line.”

Kreeger outlines the variables in several possible production scenarios. “For example, suppose your coating operation only does three color changes a day and works 244 days a year with burdened cost of $660/hr,” he says. “Burdened cost is the cost of production downtime, and may range from $400/hr to as high as $4,500/hr.

“The systems have eight auto guns spraying 20 lb/hour of powder with 50% transfer efficiency. Powder cost is $3/lb.”

Plugging all these values into the nVision software, users would discover that a cyclone reclaim booth with 90% recovery efficiency and 10-min color change capability is the lowest-cost option.

“But suppose you add new colors to the product line and now require 12 color changes each day,” Kreeger posits. “Using all the same parameters as before, the outcome would be much different. With the additional nine colors, it would now be more profitable to use a reclaim booth with 90% recovery efficiency and 10-min color change capability.”

According to Kreeger, the package is not limited to powder coating operations; it also offers features for evaluating liquid paint operations such as an interactive electrostatic calculator. Users can see the economic effects of changing process parameters such as gallons of paint sprayed per year, volume solids, film thickness, cost of paint and transfer efficiency.

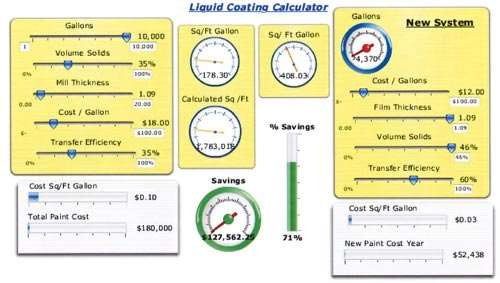

Kreeger provides another example: Comparison of an air electrostatic spray system with a system using a rotary atomizer, which offers higher transfer efficiency and the ability to use coatings with a higher volume of solids.

“Suppose your coating operation uses 10,000 gal/yr of paint containing 35% solids at a cost of $18/gal,” Kreeger says. Dry film thickness is 1.09 mil, and transfer efficiency is 35%. By switching to a rotary atomizer, you can increase both the percent solids in the coating material and transfer efficiency.

“If transfer efficiency increases from 35% to 60% and percent solids increases from 35% to 45%, annual paint cost savings are more than $127,000 or 71%,” he explains. “Even if percent solids remained at 35%, the increased transfer efficiency would result in substantial annual savings.”

Other questions the software can help answer include powder versus liquid application and the effects of changes in line speed and parts per hook. “By plugging in such variables as hours per day running, shifts per day, days per year and parts per hanger, you can calculate how many more parts per year can be coated by increasing line speed and/or hanging more parts per hook,” Kreeger says. “The software can be a useful tool in visualizing which variables will have the most effect on production on your coating lines.”