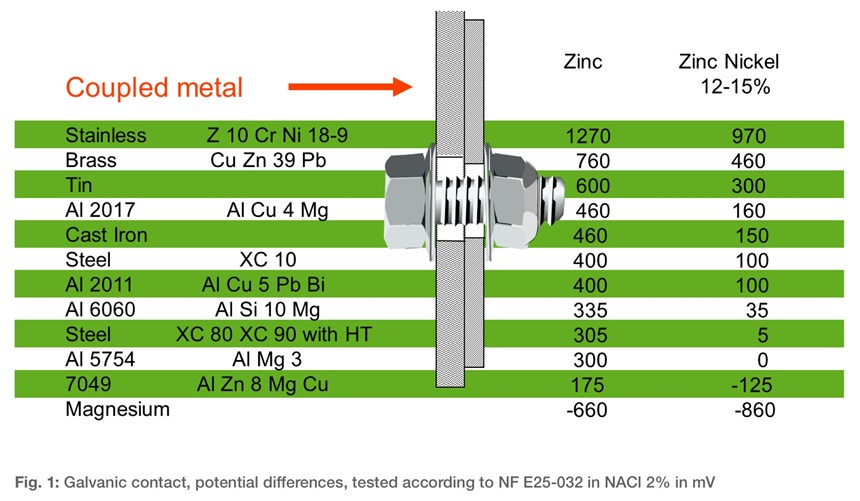

Fasteners for the automotive industry must be protected from corrosion to ensure a long service life. Typically, pure zinc or zinc alloys are used as cathodic corrosion protection layers that can provide 720 hours or even more of neutral salt spray resistance, depending on the chosen system. In addition, zinc-nickel systems easily withstand the majority of cyclic corrosion tests and reduce the risk of galvanic corrosion.

But a fastener may have many more requirements than just extended corrosion protection.

Featured Content

Appearance is usually an important criteria and depends on the type of zinc or zinc alloy, as well as the passivate. It can be colorless, silver, bluish, iridescent or black. Topcoats can influence and stabilize the appearance as well. Depending on the final application on the fastener, other properties, like hardness, wear resistance or electrical conductivity can come into play.

Arguably, the most important mechanical property of a fastener, however, is a defined coefficient of friction (CoF).

Friction is All Around Us

Whenever two objects in contact move against each other, friction is involved—sometimes more, sometimes less. For example, to make ball bearings work effectively, the coefficient of friction, often symbolized by the Greek letter μ, must be as low as possible, typically 0,0015. A CoF of 0,005 – 0,03 is what makes ice skaters slide over a frozen lake. In contrast, there are also situations where high friction is beneficial. To ensure for example that cars can stop safely, brake systems (brake pad vs. brake disk) have a CoF 0,4. The friction value between tires and the asphalt on the road is approximately 1,0—clearly, the higher the better, to keep cars where we want them.

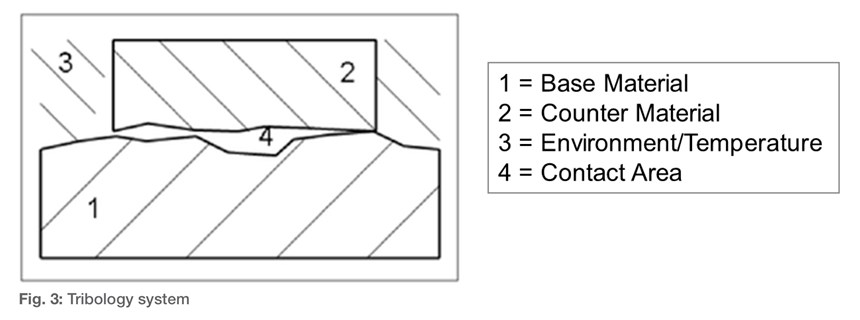

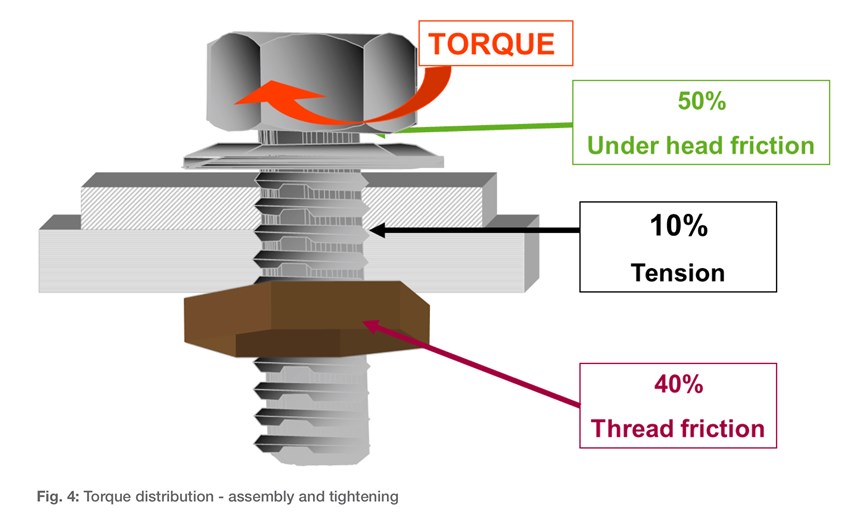

Friction is the resistance that one surface or object encounters when moving against another one. It is a system property, and all involved surfaces and parameters must be considered. For simplicity, here we are discussing only two-body friction. The CoF is important to establish the joint and the clamping force to keep the joint stable. The clamping force is very much influenced by the applied assembly force or the torque. The applied torque is distributed to different areas of the joint; approximately 90 percent results in friction and only about 10 percent in tension.

What Influences the Coefficient of Friction?

Roughly 85 percent of vehicle issues are caused by assembly problems, and many of these are related to insufficient joints. Therefore, the quality of the fasteners and most notably, the surface treatment of said fasteners, is of high importance. That’s why it also is important to understand the influencing factors that allow one to choose the best surface treatment system for each application.

As mentioned, friction is a system property, and therefore various other factors also have to be considered. Lubricants not only reduce friction but also control the actual value, provided that other factors remain unchanged. The type of corrosion protection layer has an influence as well; an organic-type coating will be different from an electrolytic-applied metallic layer. A soft zinc layer of approximately 80 HV will be different than a hard zinc-nickel layer of approximately 450 HV. The bearing surface typically consists of different materials such as carbon steel, heat-treated high-strength steel, aluminum and others. Mating nuts may be plain steel, zinc-plated, phosphated, oiled or so on. Other contributing factors are the thickness of the layer, cleanliness of the surfaces and part/counterpart geometry. It is important to understand that if any of these factors change appreciably, the entire friction system will change, as will the CoF.

There are three points in the lifecycle of a fastener in which friction plays an important role: first, when the joint is initially fastened; second, during use of the assembled product; and finally, when the joint is unscrewed. Some joints are permanent, meaning they are fastened one time and are designed to not be unscrewed again. Other joints undergo repeated screw/unscrew cycles over their lifetime, such as wheel nuts.

What is the correct CoF?

Unfortunately, there is no “perfect” CoF. In addition to the aforementioned influencing factors, the assembly parameters have to be taken into consideration as well. Today, the automotive industry typically requests CoF values in the range of 0,10 to 0,19, with an accepted tolerance of ±0,03.

In the case of too low a friction value, (less than 0,08), there is a potential risk of self-loosening of the joint. If the CoF is too high, there is a risk of too low clamping forces, resulting in a joint failure due to incomplete tightening or complete fracture of the screw. The industry often requests higher friction values of 0,21 or 0,24 for specific joints. This is the main task for topcoats: high CoF, but in a much tighter range. A plated surface without a topcoat may have a comparable CoF but is nearly impossible to control within ±0,03.

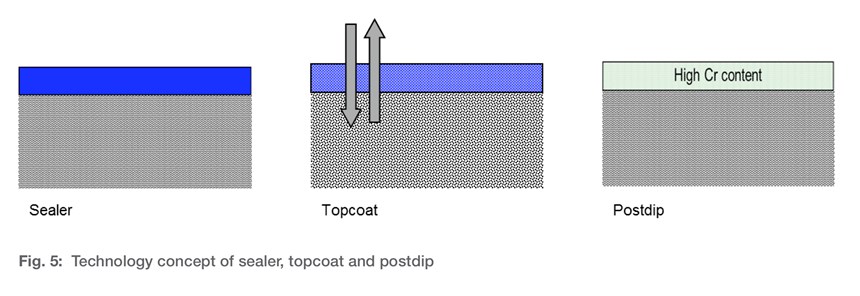

Sealers, topcoats and post-dips are available as post-treatments for zinc- and/or zinc-alloy-plated fasteners, but what exactly are sealers, topcoats and post-dips in the world of electroplating?

Sealers are organic (acrylic) polymers. As the term “sealer” suggests, their main task is to seal the surface. This is accomplished by closing all of the pores of the surface to maintain a distinct separation between the plated layer beneath the sealer and the hostile surrounding environment. Basically, a sealer is “waterproofing” for metal. It is important to know that mechanical damage, such as chipping from stones, will decrease their protective effect.

Topcoats contain organic and inorganic materials. The former is often a polyethylene wax and the latter component can be, for example, silica nano-particles. These nano-scaled silica particles enhance the re-hydration of the passivate and act as a corrosion inhibitor. The organic wax provides necessary friction control.

Finding the optimum topcoat requires an exact knowledge of the complete tribology system with all involved parameters. This is only possible in a cooperative dialog between customer and supplier.

Post-dips, such as chrome salts, are inorganic. They mainly increase the layer weight of the passivate film and therefore the corrosion-protection properties. On black passivates, the post-dip fills the spongy structure.

Due to the incorporated silicon dioxide particles, certain products can increase the salt spray resistance of a plated fastener by 100 hours or more; those particles are also responsible for a self-healing property of the entire system. These products can assist in achieving a better appearance of passivated parts, because they reduce the iridescence of blue or transparent passivates and help to get more uniform and deeper black passivates. The type and quantity of wax are responsible for controlling the coefficient of friction. Thus, a tailored CoF can be designed according to customer requirements. The typical variance is ±0,03.

Friction is critical for the assembly and therefore a quality parameter for fasteners. Again, it is not a single parameter but a complex system that needs to be analyzed thoroughly. Topcoats can control the friction of fasteners in narrow ranges, regardless of whether high, medium or low friction is required. They can be tailored to customer requirements, and different formulations are available for different uses, like fastening against steel and/or aluminum.

Rainer Venz is managing director at Coventya International GmbH in Germany. Visit coventya.com.

RELATED CONTENT

-

Copper Plating on Aluminum and Aluminum Alloys

How can I plate copper on aluminum?

-

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

-

Smut and Desmutting

Question: I am new to this industry and have heard about smut and desmutting operations.