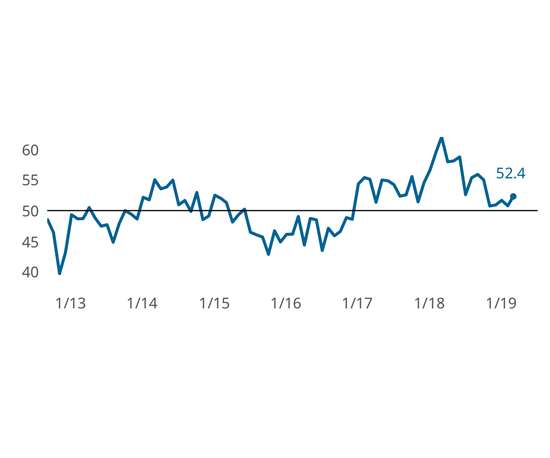

Finishing Activity Up Modestly in First Quarter of 2019

Gardner Intelligence’s Michael Guckes reports the March Finishing Index was 52.4.

The Gardner Business Index: Finishing Index closed the first quarter of 2019 with a March reading of 52.4. Compared to the Finishing Index’s all-time high (reached a year ago), the Finishing Index has fallen 17 percent. This should not overshadow the fact that March marked the Finishing Index’s 27th consecutive month of activity expansion. Further, the Finishing Index has rebounded three percent since it’s most recent nadir in November. The latest Finishing Index reading was supported by a sharp increase in production activity, followed by supplier deliveries and new orders. Employment, exports and backlogs all pulled the index lower. Both exports and backlogs experienced contracting activity in March.

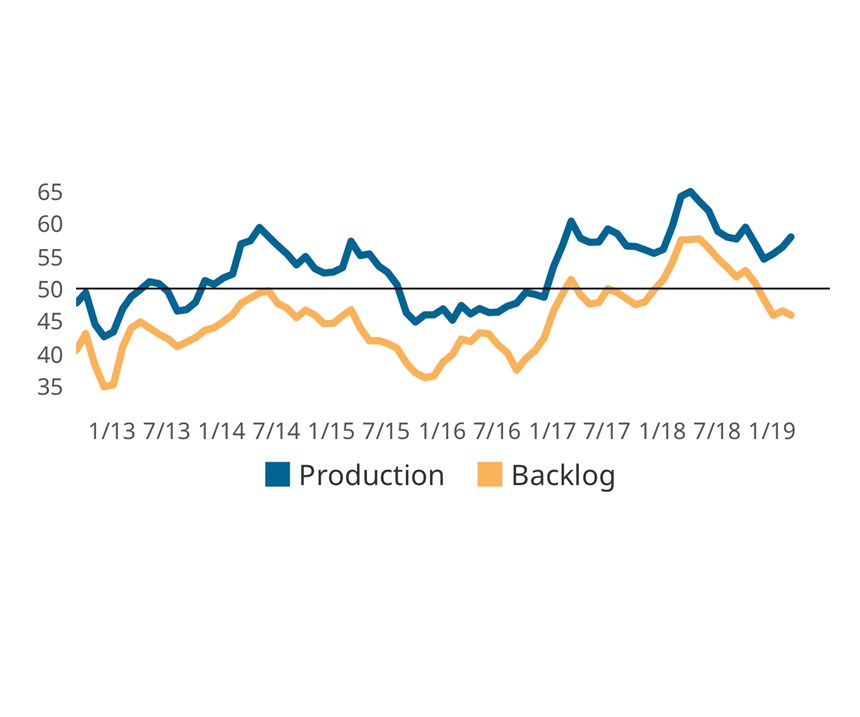

Activity in new orders rebounded after registering a surprising contractionary reading in February. Part of the reason for the improvement in new orders may have been due to improved export activity, which registered its best reading since May 2018. The month’s relatively stronger reading for production as compared to new orders put pressure on backlogs which fell to a two-year low. Production activity has outpaced new orders activity in every month since December of 2018. As a result, it is not a coincidence that backlogs readings during that period have reported contracting activity.

RELATED CONTENT

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

Smut and Desmutting

Question: I am new to this industry and have heard about smut and desmutting operations.

-

Aluminum Anodizing

Types of anodizing, processes, equipment selection and tank construction.

.jpg;width=70;height=70;mode=crop)