Full Speed Ahead

Choosing powder control systems to maximize productivity and efficiency

#curing

With lean operations quickly becoming the standard over traditional production methods, time is all the more critical. Faster is most certainly proving to be better. For powder coating operations spraying more colors than ever, fast color changes are a must. Those color changes could take as little as 20 sec with spray-to-waste systems or 10 min with reclaim systems.

The heart of these speedier operations is improved process control. At their most basic level, these systems control various gun, pump and system parameters. They are designed to provide a means for operators to monitor and adjust gun and system operations.

Featured Content

The goal is to determine the equipment settings needed to produce one good part as efficiently as possible, and then use the same settings to spray each part the exact same way—and do it without waste, error and lost profits. Then, repeat the same actions as long as nothing changes.

Because change is inevitable, the most advanced control systems must allow for easy adjustments to be made by the operator or even go so far as to anticipate change and be able to make adjustments to accommodate it. Quality control is all about repeatability.

There have been many advances in process control technology over the years that have improved the powder coating process, but more recent advances have the newest process controls significantly raising the bar. These next-generation manual and automatic control systems continue to further allow users to reduce powder usage while saving time and energy, reducing housekeeping, better accommodating just-in-time demands for color changes and, most importantly, producing the highest possible cured film consistency.

Closing the Loop

Regulating the flow of powder to the guns at the optimal level is a key component to maximizing finishing results. The problem is that the compressed air feeding the powder system changes constantly and unpredictably. Air pressure rises and falls as other plant devices draw air. If left unchecked, this change in compressed air at the input to the powder regulators can cause the same sort of variation in the powder process.

That’s why the newest process control technologies have paid a great deal of attention to powder flow. Older technologies often relied on manual regulators, which could have some inherent limitations with accuracy (how consistently powder is delivered once the control is set or how close to the desired value the regulator can be adjusted from the beginning).

Most modern powder systems, whether manual or automatic, provide a closed-loop flow control over powder flow. Closed-loop flow control adjusts air pressure input to the pump, regardless of fluctuations in plant air pressure, to maintain consistent, repeatable powder flow. Such control means consistent, repeatable coating coverage for optimum finish quality and operating efficiency.

Operator ease is another important factor when considering process control technology. Generally, the more user-configurable presets available, the easier it is to build recipes for specific parts and powders. Presets allow operators to adjust gun control parameters such as flow rate, atomizing voltage and current.

Controlling Manual Guns

Many of today’s manual guns are focused on ease-of-use by the painter. These guns tend to be compact, lightweight and well-balanced, making them ideal to meet the performance demands of faster line speeds and shorter runs that come with leaner manufacturing. The system controls also feature procedures that are easy to learn to reduce training time required for operators.

With these new generation of guns comes the need for a new generation of controls. One of the latest innovations is the use of controls directly on the gun. The back of the gun features a keypad and display. Also included on the gun are a gun purge button and a mode selection button that allows for quick mode changes on the fly for both presets and powder flow rate. The gun is also linked to a controller that provides additional control capabilities, such as closed-loop digital flow control and automatic feedback current control.

Having controls directly on the gun allows the operator to know the exact gun setting without taking focus off the part being coated. This allows for even greater flexibility, enabling almost instant response to product and color demands that can change by the minute on the coating line.

Lean Systems

Such systems, with controls directly on the gun, can be used in reclaim or non-reclaim powder coating systems. Non-reclaim (lean) systems are being used where it may not be economically justifiable to reclaim powder coatings. One development that has allowed these lean systems to be economically feasible is dense-phase powder delivery, which provides enough boost in first-pass transfer efficiency to considerably narrow the cost gap between reclaim and spray-to-waste.

Dense-phase is a reference to the dense powder in the transport tubes. The control technology focuses on dense-phase powder transport with closed-loop digital flow technology. Moving more powder with less air results in higher transfer efficiency compared to conventional venturi-style pumps. Using less compressed air to propel the powder to the gun means less overspray, more powder on the part and greater powder material savings. With the improved transfer efficiency offered by dense-phase technology (more than 70% first pass transfer efficiency in some cases), many powder coaters are choosing to spray-to-waste rather than reclaim powder.

Such systems use a manual or automatic purgeable design in both suction and transport directions for ultra-fast color change. This added weapon in the color-change arsenal allows for automatic color changes in 20 sec or less in a lean cell. This super-fast color change capability allows guns and hoses to be rapidly purged for a second color.

One playground manufacturer is using dense-phase technology for spraying textures and metallics. The result has been an increase in line speed from 4 to 5.5 fpm. The same technology has also reduced color change time from 3.5 min to 45 sec, which has had a tremendous impact for a company that averages 40 color changes/shift and is running two shifts/day. Higher transfer efficiency has reduced scrap powder by as much as 80%.

Taking Lean to the Limit

New spray booth designs can help further “lean out” a company’s powder coating operation. In situations where color-change times of less than 10 min would not provide any further increase in production throughput, booths that can achieve 10-min color change with powder reclaim capability may be the best choice.

Canopies for these booths are typically made of specially engineered, nonconductive plastic composite materials that do not attract powder. What little powder does collect on the inside surfaces is easily blown off, either intermittently during operation to keep the amount of “in-process” powder to an absolute minimum, or during the color-change process. These booths utilize controls that determine a specific and most effective sequence of operations to facilitate fast cleaning of the powder feed system, spray guns and interior booth surfaces in preparation for the next color to be sprayed.

If the painting operation is the limiting factor in production throughput and the capability to change colors in as little as 20 sec brings a better return than what the customer would otherwise save in reclaimed powder, booths designed to take full advantage of the ultra-fast, color-change capability of dense-phase powder delivery are the answer.

Referred to as “lean cell” booths, these large, open-face painting stations provide laminar air flow from directly behind the spray guns, which can be either manual or automatic, into the side-draft collector module. Sized with the proper air draw capacity, this type of booth enables any airborne powder from the last color sprayed, and from gun purging during color change, to be effectively evacuated from the coating area and quickly drawn into the collector module, preventing any cross-contamination when the next color is introduced.

What enables changing color with powder in as little as 20 sec is an integrated system comprised of a bank of unique, dense-phase, color-change valves, a single powder delivery pump and a number of dedicated-color powder delivery hoppers. Specialized controls enable an operator to simply press one button to activate purging of the previous color and press another button to select the next powder color. Everything else is completely automatic.

During the color-change sequence, the powder delivery hose, pump and gun are purged using compressed air in a series of controlled low- and high-pressure bursts. Low-pressure pulses remove the bulk of the powder in the delivery path, and high-pressure pulses “scrub” the internal surfaces clean. The next color is then introduced into the powder hose and gun, and the next part on the conveyor, separated by only a few feet from the previously sprayed part, is ready to be coated with the new color.

Total Control

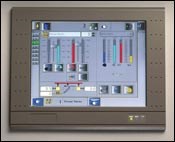

Not long ago, powder coaters had to have a separate control for each gun—even in automatic powder coating systems. Now, there are control systems that integrate all powder control functions and provide a touch-screen graphical interface for a single view of all system settings. These systems typically feature closed-loop digital flow technology and provide for recipe-driven automatic control of all system parameters.

Parameters can include booth airflow, spray gun air control, electrostatic control, powder pump operation, gun triggering, part detection and gun motion control. Setting each of these manually for every gun, every part and every powder would be physically impossible—and each manual setting has the potential for error, which could be compounded when making dozens or hundreds of changes at a time.

Integrated control systems allow all parameters to be stored together as a single part recipe that can be activated with a few keystrokes. Some of today’s systems can accommodate up to 250 presets to optimize system performance over the widest variety of part profiles and configurations.

These advanced controls can also accept input from part identification sensors for gun triggering and in/out positioning of guns. Some systems even offer multiple language capabilities and voice prompts to tell the operator what product and color are coming next. This can be a big help in situations with operator turnover.

More Than Just Hardware

While control of application equipment and hardware functionality can help to optimize operating efficiency and overall system efficiency, specific production requirements (to increase productivity, add more color choices, speed color changes and so on), can oftentimes dictate a different course of action to select the coating system that’s best for a given situation.

Today, computer modeling tools are being used to test key parameters, such as lost production time, impact of color change or transfer efficiency, to help finishers take more control of their coating operation decisions. Yet, the number of variables and possible permutations can be daunting and the calculations prone to error.

Several companies now offer a number of interactive software packages for both powder and liquid coating lines that help finishers in choosing their best alternative for future coating requirements based on hard economic comparisons. Bringing visibility to these alternatives, users can quickly and thoroughly evaluate the data for upgrading or converting to a different finishing method. These tools test and evaluate the effect of any variable on overall profitability using detailed “what if” scenarios that allow for various input data so users can input what they know in the most convenient format to help them make educated decisions.

Some packages offer calculations in both English and metric units, as well as for multiple currencies. Process variables included among several computer modeling tools currently available are: booth sizing, color change, color change for automatic systems, color change for manual systems, extrusion production, gun mover speed, process controls, liquid to powder conversion, pipe coating, production estimator, recycling system, system efficiency, transfer efficiency, ROI from liquid UV, and liquid electrostatic payback.

As more and more powder coating operations manage multiple colors and look for faster color changes to meet lean operation requirements, they are investigating the next generation of process controls to improve their coating line and their bottom line. The right coating technology and process controls can save 15–30% in material costs through higher transfer efficiency, as well as provide a return on investment through reduced downtime, less energy used, less wear and tear on equipment, greater productivity and more consistent quality in both reclaim and spray-to-waste systems.

RELATED CONTENT

-

Pretreatment for Painting

Better adhesion, enhanced corrosion and blister resistance, and reduced coating-part interactions make pretreatment a must.

-

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

-

Painting Over Powder Coating

How safely can they apply their wet paint over our powder coated parts?