Galvanizing, Powder Coat Give A1 Protection

Kansas City shop uses duplex coatings for extra corrosion resistance.

Frank Laster has only been in the powder coating industry for three years, but he can recognize a big need when he sees one.

The president of A1 Paint Powder Coating and Sandblasting in Kansas City, Missouri, came to the finishing industry from retail and the heating and cooling sector, where innovation and building a better mousetrap is a means of survival and not just profit.

Featured Content

What he saw when he joined A1—which his father had purchased in 2010—was the need for a coating that could impress fabricators with its corrosion protection and smooth finish.

“My sales experience in other industries taught me that the way to succeed is to do something for somebody that other people didn’t want to do,” Laster says. “It comes down to having an entrepreneurial spirit.”

With a gargantuan-sized powder coating line that measures 380 feet straight through, A1 is going after a niche market of large-size pieces that other coaters might have trouble finagling through.

The line includes a 60-foot oven, in addition to a 55-foot wet paint booth and a 40-foot sandblasting building. Everything fits just fine in a 61,000-square-foot building—a former shingle factory—located near I-435 that provides A1 plenty of room to wash, phosphate, dry, paint or powder coat, as well as bake, inspect and pack the coated parts for shipment without being exposed to the elements.

Frank Laster is the president of A1 Paint Powder Coating and Sandblasting in Kansas City, Missouri.

PowderGalv Coating

In addition to the above-average size of the booths and ovens, A1 has begun offering PowderGalv, a proprietary duplex coating that Laster stresses is a process, and not just a coating. It starts with a hot-dip galvanized coating on a part, followed by a powder coating that Laster says gives it excellent mechanical and anti-corrosion properties.

“Everybody I talk to is afraid of duplex coatings,” he says. “They have had big problems with it, and so they just avoid the process. To me, that’s an area I wanted to get into, only because so many others didn’t want to give it a try.”

Over the last several years, A1 was approached by several of its existing customers—many of whom make large, outdoor structures for water parks—asking about a better corrosion protection. In some outdoor environments, not only does the appearance of rust begin to break down the pieces, it is also aesthetically unappealing.

Fortunately, AZZ Galvanizing—which claims to be North America’s largest after-fabrication galvanizer—has a shop located right next door to A1’s shop. Laster and the AZZ people began talking about collaborating on a new coating process that would help solve some of those concerns.

“We just started testing pieces and experimenting, and we started to get some very good results,” says Laster, whose company was recently NACE CIP 1-certified.

Parts arrive at A1 for sandblasting and surface finishing, and are then galvanized before being taken to the powder coating booth and coater, where they are shipped off.

Zinc Protection

The process begins when the metal pieces are fabricated and delivered to AZZ for the protective base coating, which starts with a total immersion in a hot alkali solution to remove organic compounds. An acid pickling then removes rust or scale, followed by a fluxing that eliminates oxides from the surface of the steel and helps with the proper metallurgical bonding of the zinc coating that follows.

AZZ says that zinc corrodes at a rate 30 times slower than steel, so the hot-dip galvanizing starts with the steel being submerged in a bath of molten zinc. The steel reaches a bath temperature of about 840°F, at which time the zinc starts reacting with the steel to form a zinc/iron intermetallic layer on all surfaces of the piece, both inside and out.

Alter the hot-dip galvanized process is complete and inspected, AZZ delivers the parts to A1, where Laster and his staff start their PowderGalv process to prepare, treat and coat the material with a powder coating that finishes with a piece that has multiple mils of coating.

Laster says that, not only does the finish hold up well under harsh conditions, it has a better consistency of color and a smoother finish.

“We have had tremendous success with having such large size booths and ovens, but the biggest growth area for us has been developing the PowderGalv process and making it work for our customers,” he says.

Laster’s family purchased A-1 Paint Powder and Sandblasting from Eric and Christina Davis in 2010, who had started the company just four years earlier. Eric had more than 35 years in the coating industry, but he became ill in 2011 and reduced the amount of time he was involved in the operation.

A1’s finishing line is large, and includes a 60-foot oven, a 55-foot wet paint booth and a 40-foot sandblasting building.

Vast Experience

Laster’s father, Colonel Laster, and mother, Pat, purchased the Davis’ part of the business, and brought on son Frank to help run the operation.

Colonel Laster’s route to the coating industry has an interesting twist. He retired from the U.S. Army in 1987 and started a cattle feeding operation in nearby McLouth, Kansas. A few years later, he moved the operation to Syracuse, Kansas, and grew the business from feeding 1,000 to 10,000 head a year.

In the mid-2000s, Colonel added to his business empire by purchasing Sun Energy Ethanol Plant in Walsh, Colorado. They even entered the publishing field when he and Pat bought their hometown newspaper, the Syracuse Journal. In 2010, Colonel and Pat sold the newspaper and moved to Kansas City, where they purchased a partnership in A-1.

Pat had a full-time career as a registered nurse, in addition to raising a son and three daughters with Colonel. In 1994, she retired and moved with Colonel to western Kansas where she became an integral part of his ranching operations. Pat runs the business side of the various companies she and Colonel have owned and is now in charge of the business office at A-1.

Frank came into the mix in 2012, and also has a varied business background. He graduated from the University of Kansas and attended Field Artillery Officer Basic Course as a Second Lieutenant before serving in the U.S. Army Reserves. His business career began in 1991 when he joined Osco Drug—now known as CVS Pharmacy—and worked as a manager in Kansas and Missouri.

In 2002, Frank joined a heating, cooling and plumbing company as a sales associate, but left in 2006 to manage Colonel’s ethanol plant in Colorado. He returned to Kansas City a year later to the HVAC company as sales manager, turning it into one of the largest in the metro area.

In addition, Frank’s wife Christy joined the company and Pat has turned over the business operations to her.

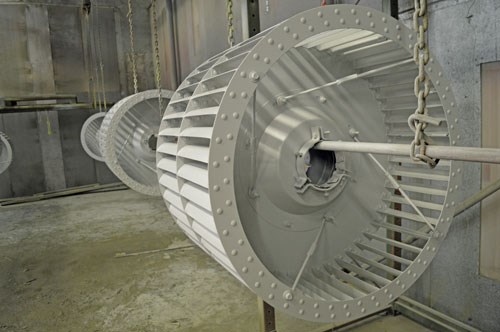

A1 also paints medium sized to larger parts, such as fans and turbines.

Growing the Business

When Colonel and Pat purchased A1 when Eric became ill, they asked Frank to become a partner in A-1, where he now handles customer relations and sales.

“We really liked what Eric had started here, and the approach he was taking to grow the coating business,” Frank says. “My goal in coming in was to take us to the next step, and I think we have an approach that will work.”

A1 hopes to grow their business by going after niche markets, namely the large parts that need coatings and corrosion resistance in harsh environments, two things that don’t always go hand-in-hand.

When Frank saw some of the larger parts coming into the shop, he decided to target that market and see where it could take them.

“It’s one thing to go after a niche market,” he says. “But you still have to do the process, and do it well.”

One of the selling points for A1 is not only having the large coating booths and ovens, but they having enough space in its facility to house parts and materials, as well as to maneuver parts through the lines. That includes making tight radius turns to send parts being cleaned or coated back through the facility to get finished or to be sent to the oven.

“Even with a 60-foot oven, I’ve seen similar facilities that had difficulty making the turns,” Frank says. “We can have 55-foot gates and even those department of transportation big, overhead signs, and they fit very well in our line. That’s a great option to have.”

Regional Coater

As Frank began surveying the regional market in Missouri, he found that there weren’t too many other coaters that could match his operation’s size. The closest he found was about five hours away from the Kansas City area, which made A1 stand out when companies needed large parts coated.

In fact, it’s made A1 more of a regional player, offering services to several Midwest states and major cities. Couple that with the PowderGalv formulation they are offering, and A1 has set itself apart from others in the services they offer to large-part manufacturers.

“We’ve really tested this process a lot,” Frank says. “When we started back in 2012, it didn’t work exactly as we wanted and we had some failures as we tested it. It wasn’t all flowers and roses; there was some manure there, too.”

One of the failures occurred several years ago with a company that makes large water park rides. But Laster and his team went about finding the reason why the coating failed, and they fine-tuned the process so that it won’t happen again.

The PowderGalv process has been successful in parts such as columns, light poles, rails, fencing, water parks, OEM parts, booms, manufactured truck racks, trailers, hoppers, tanks, large commercial cabinets, bridge beams, fire protection piping and structural frames. Customers have included Croft Trailers, Splashtacular Water Parks, Mark One Electrical, KC Fence, Dust and Pro Paper Products, Ferguson Fire and Fabrication, Brock Grain Systems, Associated Wholesale Groceries, American Fence Company and Chili’s restaurants.

The liquid coating projects have included tanks, railing, hand rails, beams, hoppers, truck mounted cranes, fire protection piping, railroad parts and others. Some of those customers included Kansas City International Airport, Crown Center, BNSF railroads, Boulevard Brewery and Missouri’s highway department.

Niche Customers

“It is nice to work with a business that stands behind their word,” says Michael Pistone, owner of Wrought Iron Works in Kansas City.

“A1 understands that painting is the last part of the project, and the importance of meeting promised delivery times,” says Travis Bowers, who worked for a steel company that used A1.

But with the size of its booths and ovens, Laster understands that his shop is not for everyone, and so he targets as new customers those with a certain revenue so there is a comparable fit in doing business with that customer.

A1 recently hired a new operations manager so that Laster could spend time each month talking to those manufacturers who could benefit from A1’s larger capabilities, as well as better develop its relationships with current customers.

“I’m always trying to find out what is new out there, and staying on top of things so we are not stagnant,” he says. “In addition to our metro area, we are talking with people all over the U.S. We have certainly opened ourselves up to a lot more people that we are talking with.”

Laster says the beauty of the coatings industry is that other shops—just like his at A1—try to specialize in certain niches that makes the market easier to target. There is the automated small batch coater, the medium size piece coater and other specialists that A1 is not competing with.

“I don’t want to do patio furniture or wheels,” Laster says. “We know who we are, and that is where our focus is. The best thing is that our PowderGalv is in its true infancy, and we think it will grow very well from here.”

In November, Laster gave a presentation at the Fabtech show in Chicago, speaking on the topic “Painting Over Hot Dip Galvanizing” along with Kevin Irving of AZZ Galvanizing. While Laster demonstrated the significant corrosion protection that PowderGalv gives parts, he isn’t as concerned that others will steal his thunder by adopting the process in their shops.

“I know the amount of trial and error, and the testing we did to get this right,” he says. “It goes back to why this market wasn’t served as well before, and it was because duplex coatings scare off some people. But what we have done with this is exciting for us and our customers, and it has worked out extremely well.”

For more information on A1 Paint Powder Coating and Sandblasting, please call 816-241-1200, or visit a1powdercoatingpainting.com.

Originally published in the December 2015 issue.

RELATED CONTENT

-

Painting Over Powder Coating

How safely can they apply their wet paint over our powder coated parts?

-

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment

-

A Current Affair: Examining the "No Amperage" Phenomenon

If you are performing a coating process that requires the use of a rectifier, you may have experienced the "no amperage" problem. Here's a look at the phenomenon and some solutions…