Getting HIP: Improving Die-Cast Substrates for Anodizing with Hot Isostatic Pressing

Hot isostatic pressing (HIP)—the simultaneous application of heat and high pressure—is a means to enhance die-cast substrates for metal finishing. This study deals with die-cast fuel pump components manufactured from alloy ADC6, a magnesium-containing aluminum alloy most similar to American designation 516.

Hot isostatic pressing (HIP)—the simultaneous application of heat and high pressure—is a means to enhance die-cast substrates for metal finishing. HIP consolidates component microstructure by refining complex phases and intermetallic compounds and healing over voids. Components of all sizes and shapes can be processed without distortion of complex features and surface tolerances. HIP improves component strength, ductility and fatigue life and yields a smooth, polished surface with more free aluminum available for formation of the anodic aluminum oxide.

Case Study: Fuel Pump Die Castings

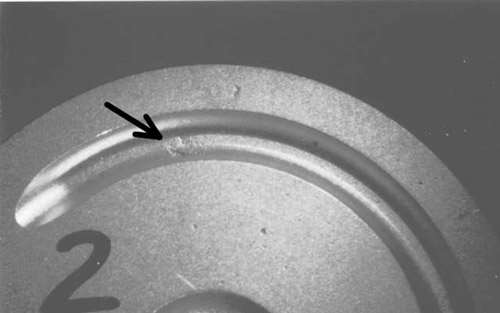

This study deals with die-cast fuel pump components manufactured from alloy ADC6, a magnesium-containing aluminum alloy most similar to American designation 516. Table 1 presents the chemistries for the two alloys. ADC 6 is a high-strength, low-alloy aluminum die-cast material. Whereas these alloys are unique in that they are among the die-cast alloys easiest to anodize, these particular castings posed problems during casting: the castings consistently exhibited porosity in critical areas for component operation. Consequently, process solutions were trapped within the porosity during anodizing, and the finished castings exhibited white residue upon drying, which led the customer to believe that anodizing was causing the problem. (See Figure 3.)

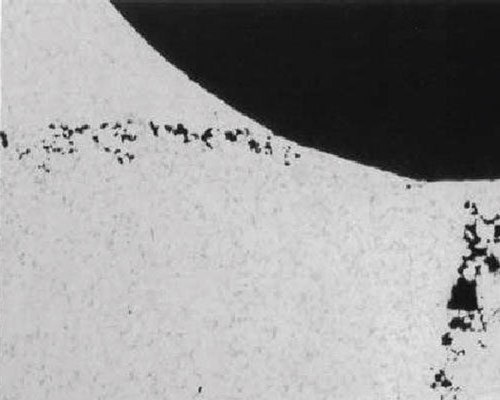

Metallographic analysis of the castings in the groove area determined the presence of porosity within the cast microstructure. Worst-case examples exhibited surface-connected porosity, which explained the solution entrapment that occurred during anodizing. More consistently, subsurface porosity was isolated within this area. See Figure 4.

A Good Candidate for Hot Isostatic Pressing

The conditions set up within the die-casting process yield repeatable results such that entire lots of material can exhibit corresponding defects. Such was the case for the fuel pump die castings. Under these circumstances, entire lots of material can be HIP processed, which can save money by way of bulk processing, but more so in the savings achieved in part salvage. In addition, the defects observed were mostly subsurface defects, indicating they were ideal candidates for successful processing through HIP.

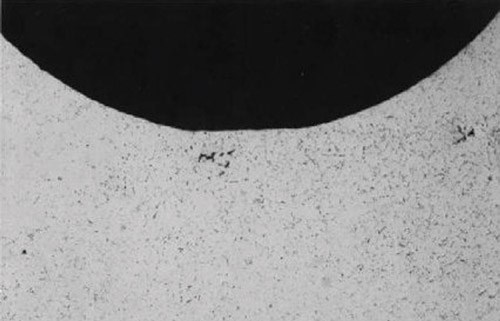

Samples were HIP’ed at 5200C and 100MPa in a sealed vessel that was evacuated and backfilled with inert gas. Metallographic examination determined the resultant cast microstructure exhibited almost no remaining porosity. See Figure 5.

The HIP process altered the microstructure of the die casting as well, appreciably solution treating the components, reducing the amount and coarseness of residual (Fe, Mn) 3SiAl2 (so-called Chinese Script Phase), but precipitating spherical Mg2Si particles. Comparative metallographic analysis before and after HIP suggest that the post-HIP samples would anodize more easily due to the more homogeneous surface. See Figure 6.

Summary And Conclusion

Aluminum components are often anodized as a means to enhance corrosion and abrasion resistance. In order for the anodizing process to successfully finish the surface with a uniform and continuous oxide, the surface must be as homogeneous and aluminum rich as possible.

In the case of surface refinement and subsequent anodizing, HIP can be considered in cases where the die-cast microstructure is overly complex, as the HIP process parameters often induce a level of solution treatment which homogenizes the microstructure. The elimination of near-surface porosity also provides a continuous surface for oxide growth, which could possibly be inadvertently opened through chemical processing.

Hot isostatic pressing is typically provided by an HIP service provider. Good communication between the die caster, metal finisher and end-user are critical to know when HIP should be recommended and implemented as part of manufacturing a high-reliability component.

Dr. Runge can be reached at CompCote International at 630-267-0225 or at jude.runge@compcote.com.